Adhesive composition

A composition and adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of deterioration and weak weather resistance, and achieve less absorption and sufficient ultraviolet rays. The effect of absorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

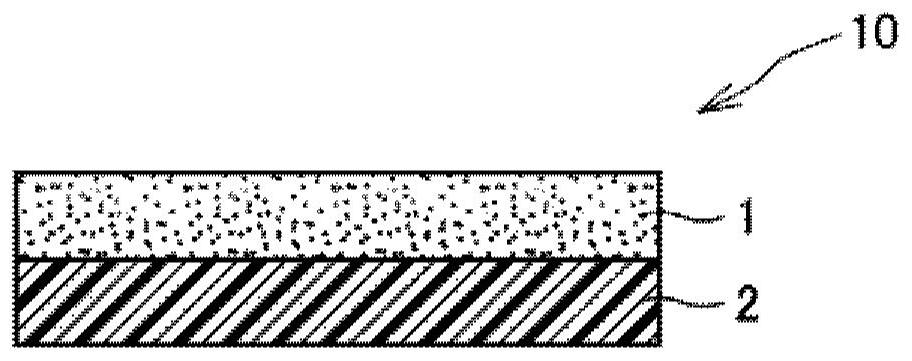

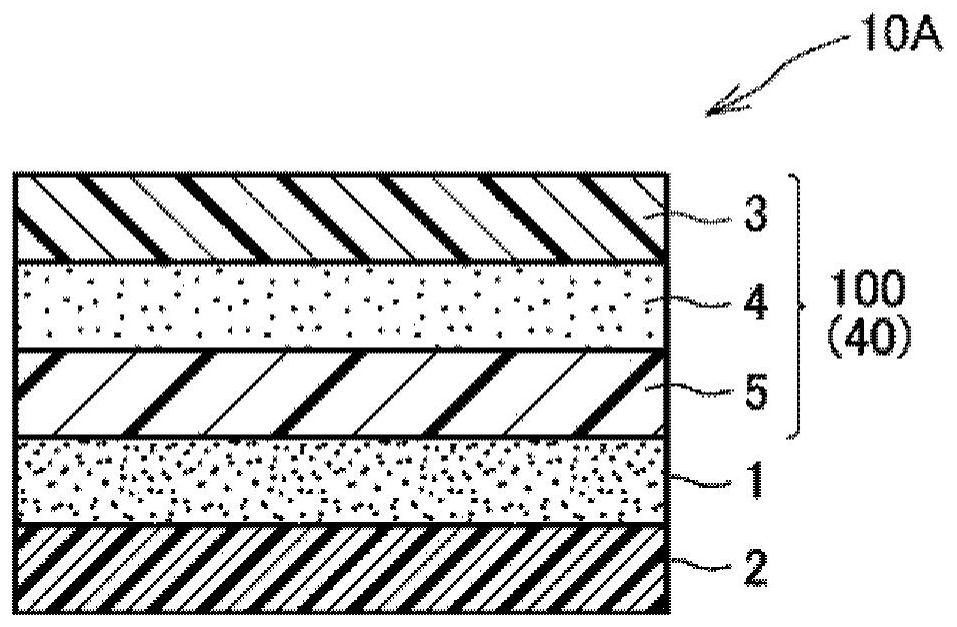

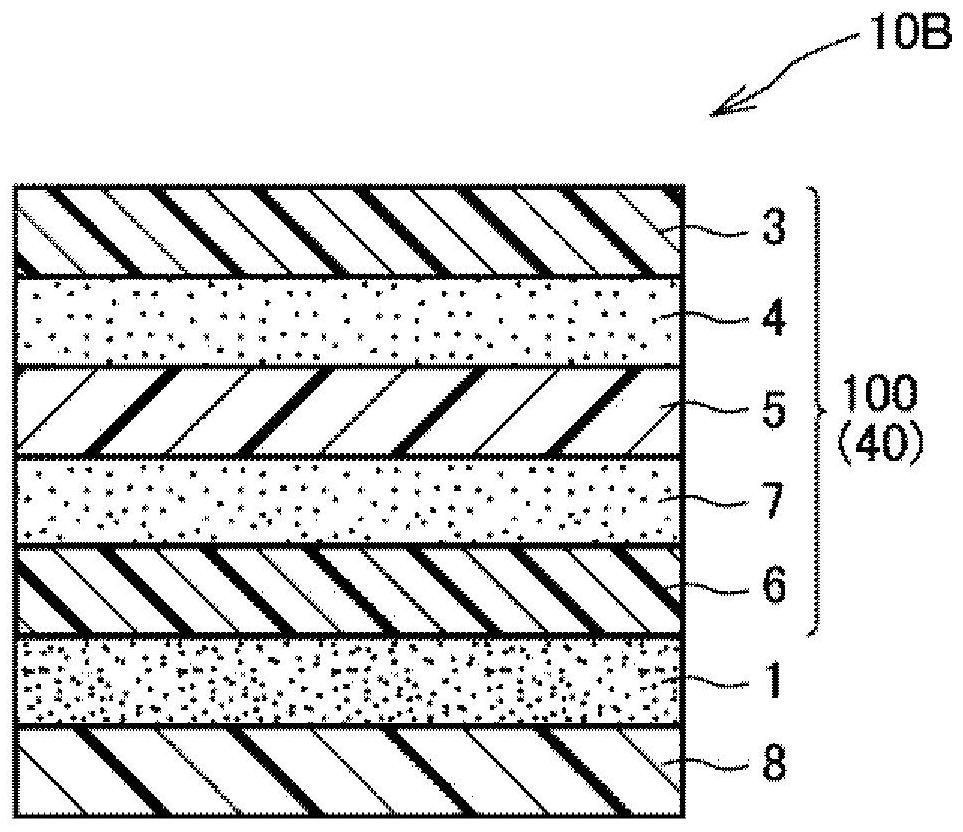

Image

Examples

Embodiment 1

[0354] (Example 1): Preparation of Adhesive Composition (1)

[0355] A crosslinking agent (F) (manufactured by Tosoh Co., Ltd.: trade name "CORONATE L ", isocyanate compound, solid content 75%) 0.3 part, silane compound (G) (manufactured by Shin-Etsu Chemical Co., Ltd.: trade name "KBM3066") 0.28 part, radical curable component (E) (Shin-Nakamura Chemical Co., Ltd. Made by the company: trade name "A-DPH-12E", 10 parts of hexafunctional (meth)acrylate compound), initiator (D) (manufactured by ADEKA Co., Ltd.: trade name "NCI-730", as oxime ester photoradical generator based on a compound) 1.5 parts, light selective absorption compound (B) (manufactured by Fujifilm Co., Ltd.; "FUV002B") 2.5 parts, light selective absorption compound (C-1) (manufactured by Otsuka Chemical Co., Ltd.: commercial product "RUVA-93", 2-[2'-hydroxy-5'-(methacryloyloxyethyl)phenyl]benzotriazole) 10 parts, and then make the solid content concentration 14% Ethyl acetate was added to obtain an adhesive c...

Embodiment 2~5 and comparative example 1~11

[0357] Except having changed each component and content of each component as shown in Table 1 or Table 2, it carried out similarly to Example 1, and produced the adhesive composition (2) - adhesive composition (16). In addition, the compounding quantity of a crosslinking agent is the mass part which is an active ingredient, and acrylic resin (A1) is the mass part of a solid content.

[0358] [Table 1]

[0359]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com