Efficient machining method and system for micromotor shell

A processing method and motor housing technology, applied in the direction of metal processing equipment, manufacturing motor generators, metal processing machinery parts, etc., can solve the problems of low production efficiency and cumbersome processing process, and achieve reduced labor intensity, efficient collection, and convenient The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

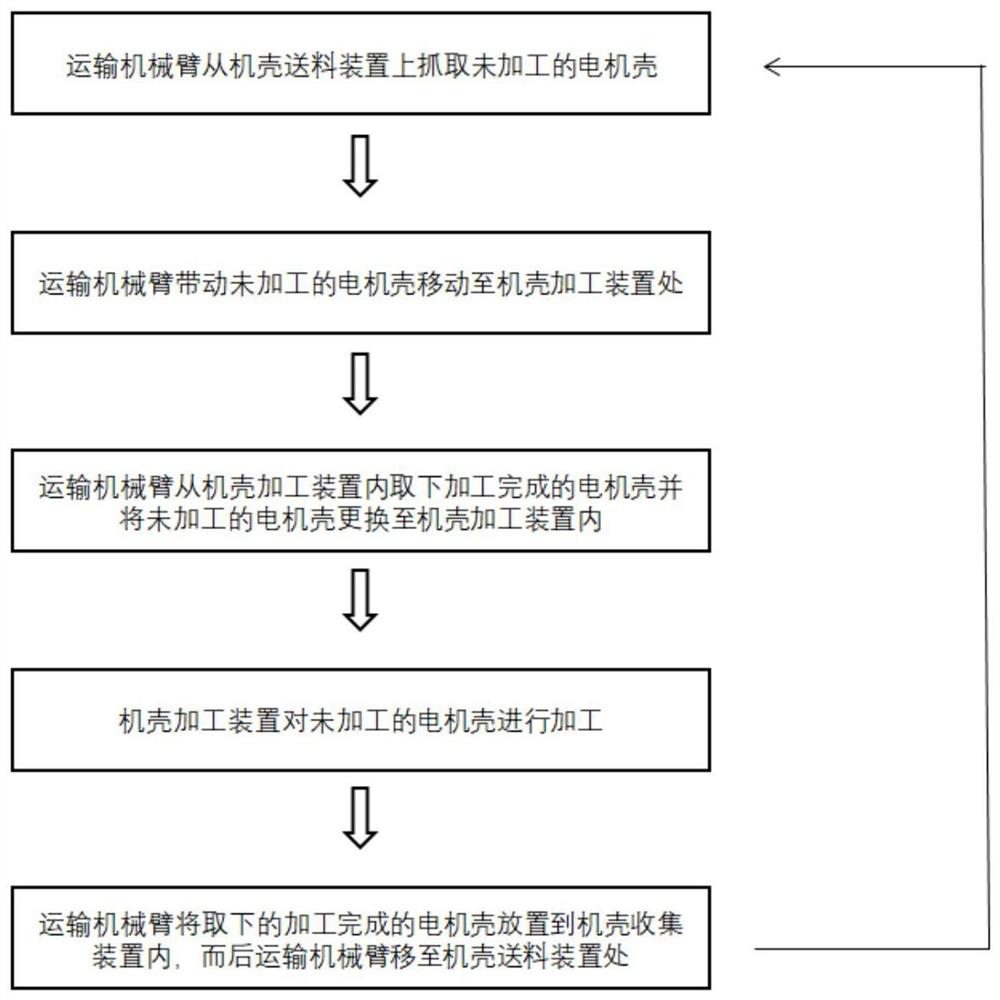

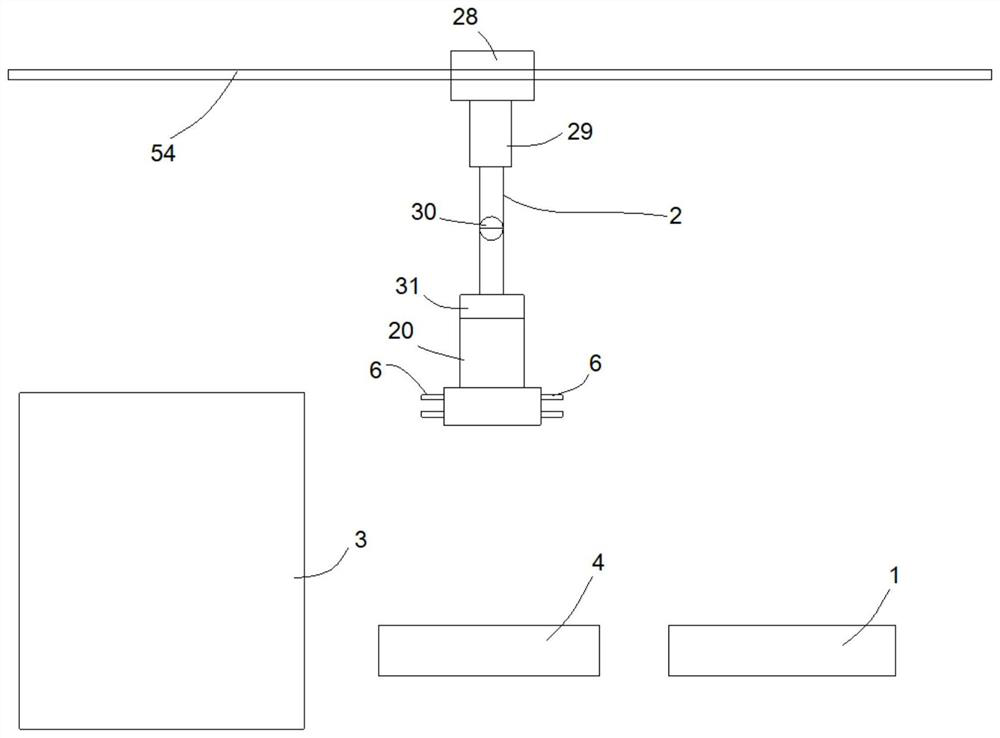

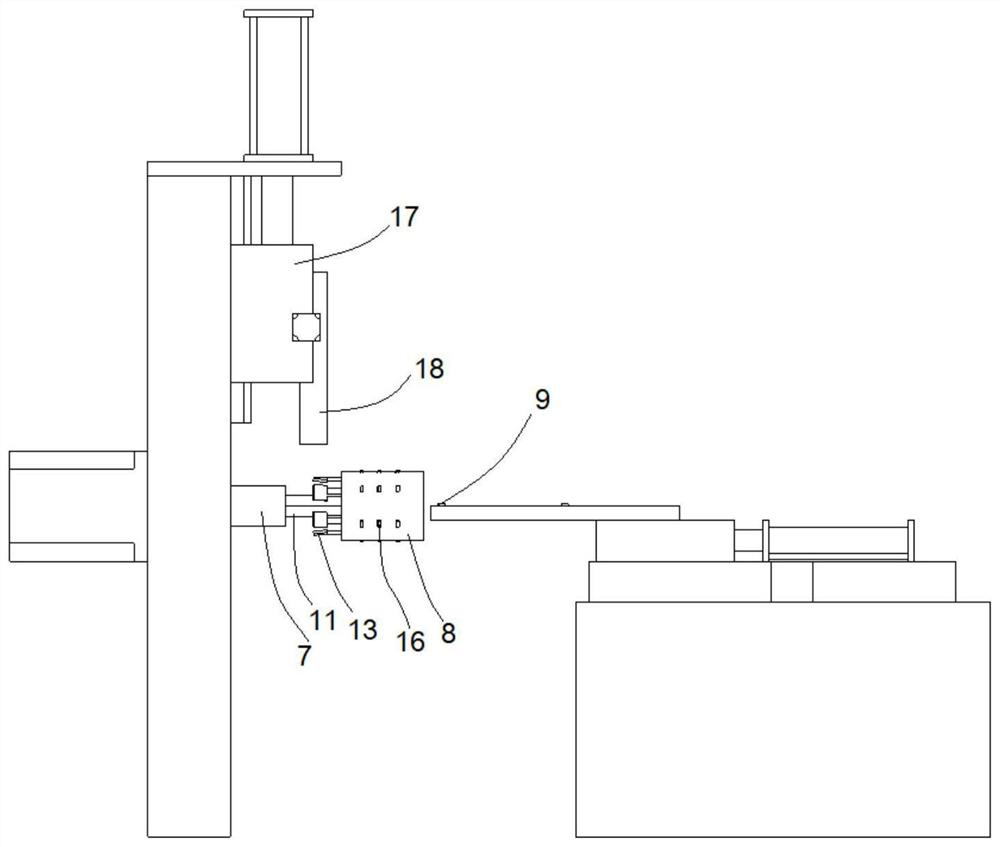

[0029] as attached Figures 1 to 10 The described high-efficiency processing method and system of a micro-motor shell include a shell feeding device 1, a transport robot arm 2, a shell processing device 3 and a shell collecting device 4, the shell of the micro-motor is a circular tube, and the shell of the micro-motor is Referred to as the motor casing 5, the processing steps of the motor casing 5 are as follows:

[0030] Step 1: The transportation robot arm 2 grabs the unprocessed motor casing 5 from the casing feeding device 1;

[0031] Step 2: The transport robot arm 2 drives the unprocessed motor casing 5 to move to the casing processing device 3;

[0032] Step 3: The transportation robot arm 2 removes the processed motor casing 5 from the casing processing device 3 and replaces the unprocessed motor casing 5 into the casing processing device 3;

[0033] Step 4:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com