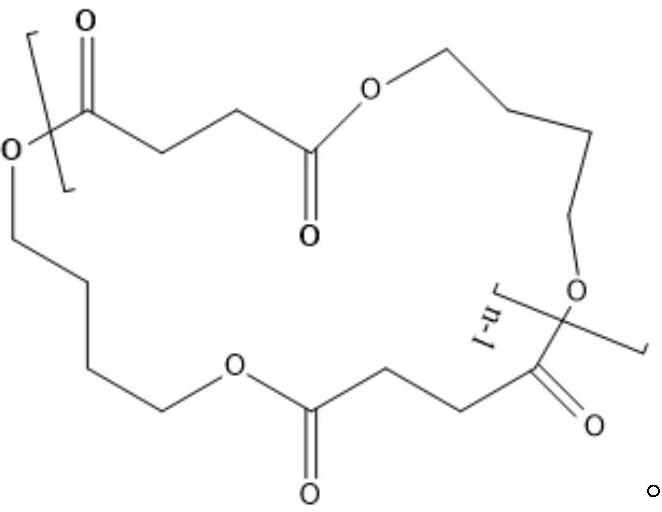

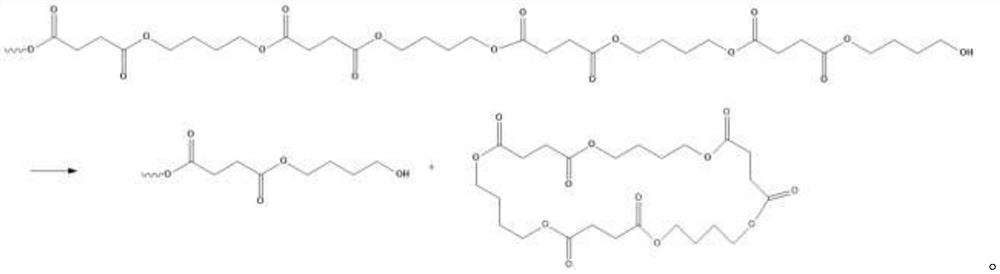

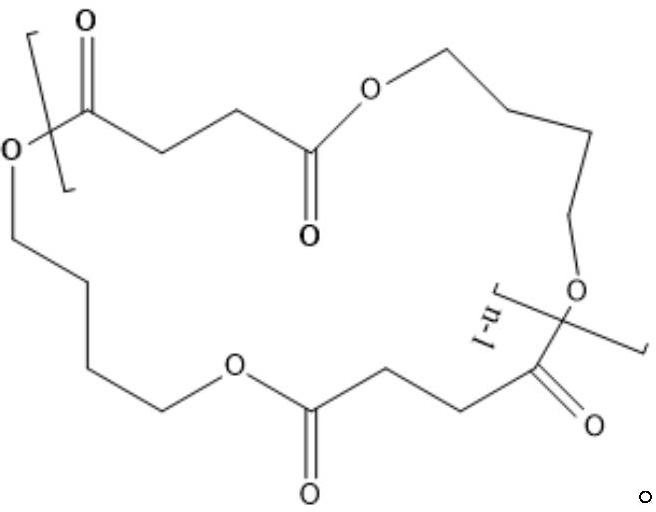

Preparation method of poly (butylene succinate) with low cyclic byproduct

A technology of polybutylene succinate and cyclic by-products is applied in the field of preparation of polybutylene succinate, which can solve the problems of uncontrollable molecular weight, poor mechanical properties, complicated operation, etc. Post-processing steps, excellent mechanical properties, and the effect of controlling molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Weigh 0.5g of stannous chloride and 50g of 50 mesh 4A molecular sieve, dissolve in 150g of ethanol, ultrasonicate at 20°C for 3 hours, and dry at 80°C until the weight becomes constant to prepare catalyst A.

Embodiment 2

[0057] Weigh 2.5g of stannous chloride and 50g of 100-mesh 4A molecular sieve, dissolve in 500g of ethanol, ultrasonicate at 60°C for 10 hours, and dry at 150°C until the weight is constant to prepare catalyst B.

Embodiment 3

[0059] Weigh 1.5g of stannous chloride and 50g of 200 mesh 4A molecular sieve, dissolve in 300g of ethanol, ultrasonicate at 40°C for 5 hours, and dry at 110°C until the weight becomes constant to prepare catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com