Application of iron-based amorphous alloy as stainless steel grain refiner

An iron-based amorphous alloy and grain refiner technology, applied in the field of stainless steel, can solve the problems of decreased toughness and plasticity of alloys, large density difference, etc., and achieve the effect of improving corrosion resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

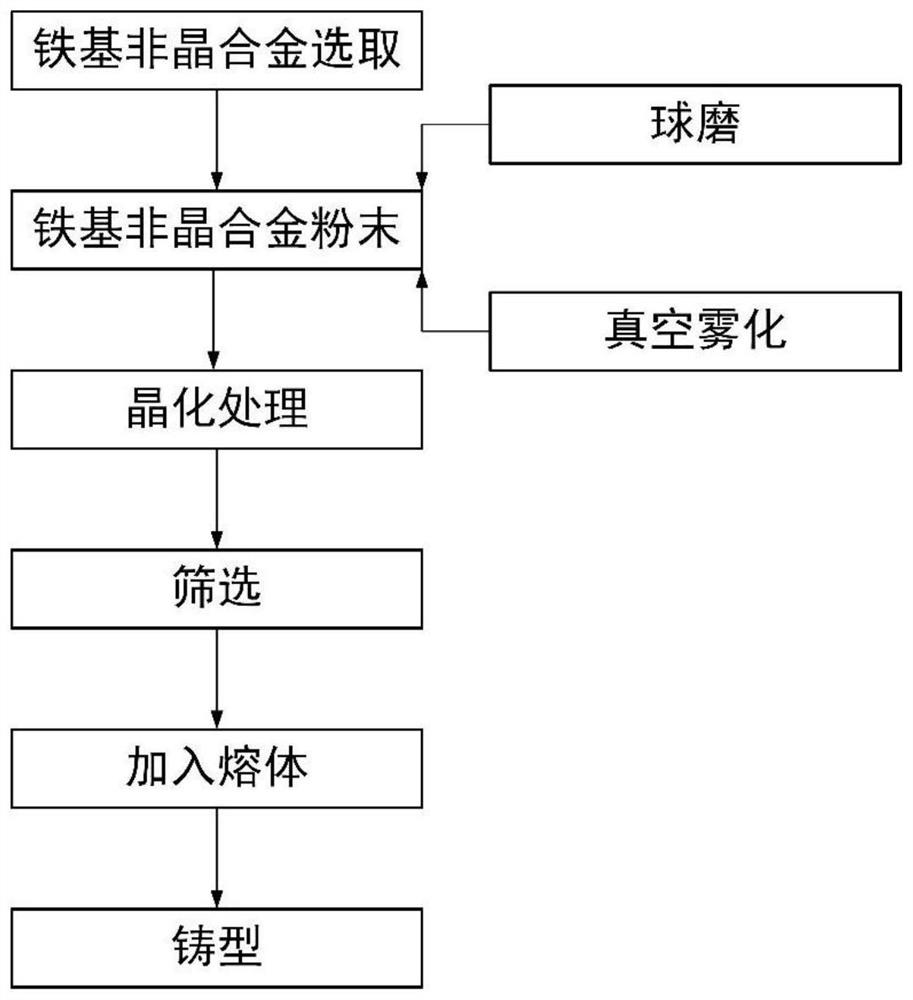

[0026] Figure 1 For the present invention embodiment of the route, according to Figure 1 The process of using iron-based amorphous alloys as a refining agent can refine the solidification structure of stainless steel castings or ingots. In the present embodiment, Fe, Mo, C, B are selected to prepare an iron-based amorphous alloy Fe 65 Mo 14 C 15 B 6 The mass percentage of the elements contained is Fe: 69.56wt.%; Mo: 25.74wt.%; C: 3.45wt.%; B: 1.24wt.%. According to the above element mass percentage content, prepare Fe 65 Mo 14 C 15 B6 Strip 100g, Prepared Fe in vacuum arc melting technology 65 Mo 14 C 15 B 6 The master alloy ingot, and then the amorphous strip is prepared by rotary quenching technology, and the amorphous strip is ball milled, the ball ratio range is 25:1, the speed is 300 rpm, and the ball grinding time is 12 hours to obtain the amorphous alloy powder.

[0027] The prepared amorphous alloy powder was vacuum heat treated at 5 °C above the transition temperature ...

Embodiment 2

[0030] In the present embodiment, Fe, Mo, C, B are selected to prepare an iron-based amorphous alloy Fe 65 Mo 14 C 15 B 6 The mass percentage of the elements contained therein is Fe: 69.56wt.%; Mo: 25.74wt.%; C: 3.45wt.%; B: 1.24wt.%, iron-based amorphous alloy Fe 65 Mo 14 C 15 B 6 The preparation method is substantially the same as the preparation method described in Example 1, only the following differences: the ball material ratio range is 40:1, the speed is 700 rpm / min, the ball milling time is 36 hours; the condition of vacuum heat treatment is 5 minutes above the conversion temperature of the amorphous alloy glass; the crystallized powder is over 1000 mesh sieve.

[0031] Take 10g of the sieved crystallized powder using the press press and wrapped with iron foil, and then added to the 20kg temperature above the melting point of 60 ° C above the melting point of 1Cr12Ni3MoWV stainless steel melt, electromagnetic stirring and maintenance of temperature for 3min, pouring into...

Embodiment 3

[0033] In the present embodiment, Fe: Cr, Mo, C, B and Y are selected to prepare an iron-based amorphous alloy Fe48 Cr 15 Mo 14 C 15 B 6 Y 2 The mass percentage of the elements contained in it is Fe: 51.29wt.%; Cr: 14.92wt.%; Mo: 25.70wt.%; C: 3.45wt.%; B: 1.24wt.%; Y: 3.40wt.%. Fe is prepared in vacuum arc melting technology 48 Cr 15 Mo 14 C 15 B 6 Y 2 The mother alloy ingot, and then the amorphous strip is prepared by rotary quenching technology, and the amorphous strip is ball milled, the ball material ratio is 25:1, the speed is 700 rpm, and the ball grinding time is 12 hours to obtain the amorphous alloy powder.

[0034] The prepared amorphous alloy powder was vacuum heat treated at 15 °C above the transition temperature of its amorphous alloy glass, kept warm for 3 minutes, and the crystallized powder was obtained. Then the crystallized powder is passed through a 1000 mesh sieve, the crystallized powder after taking 2g of sieving is pressed by a blank press and wrapped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com