Water-based epoxy anticorrosive paint for heat exchanger and preparation method of water-based epoxy anticorrosive paint

A technology of water-based epoxy and anti-corrosion coatings, applied in the field of coatings, can solve the problems of anti-corrosion, anti-scaling, poor anti-scaling ability, difficulty in meeting environmental protection requirements, etc., to improve anti-corrosion performance and mechanical properties, excellent storage stability, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

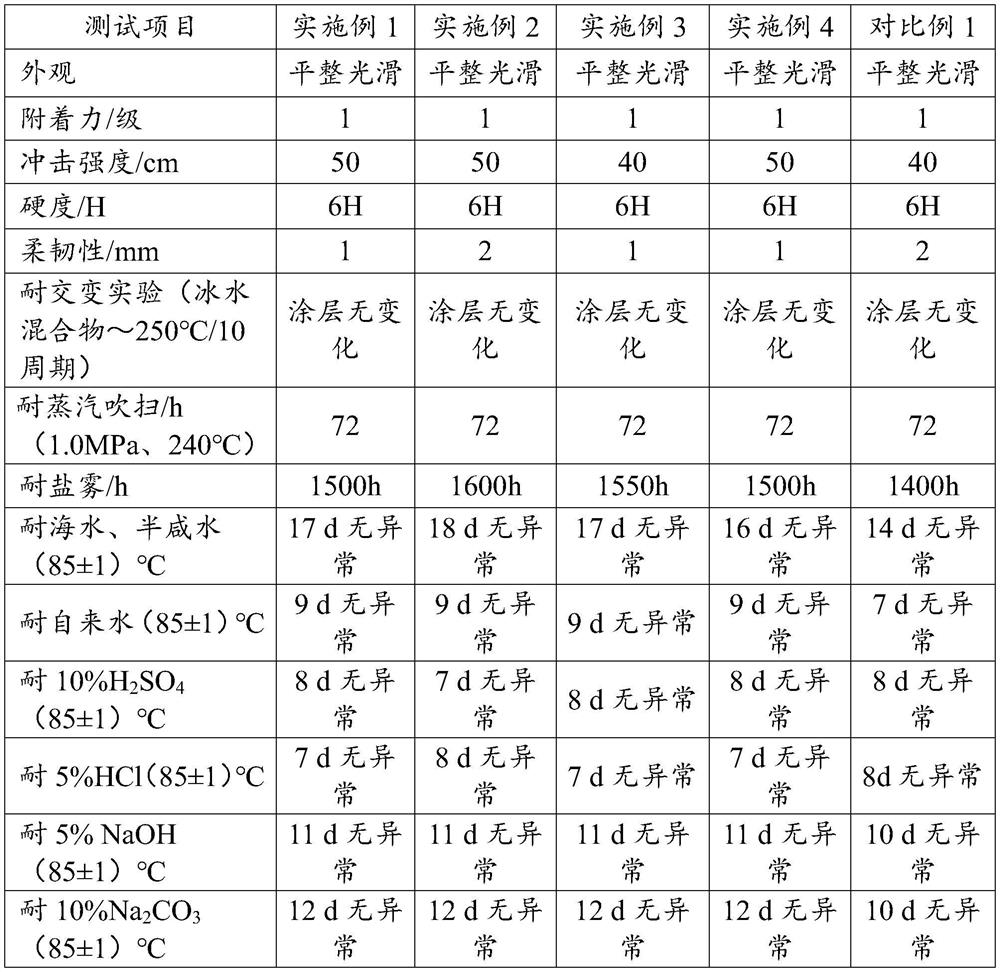

Embodiment 1

[0029] The water-based epoxy anti-corrosion coating for heat exchangers in this embodiment mainly includes the following raw materials in parts by mass: 240 parts of water-based epoxy emulsion CTW-6062, 12 parts of water-based silicone emulsion MPF 52E, 24 parts of amino resin CYMEL 303, 2.4 parts of catalyst CYCAT 4040, 195.1 parts of water-based pigment paste, 1.8 parts of defoamer BYK-019, 0.8 parts of leveling agent RM-2020, 1.2 parts of anti-flash rust agent Roybo 60, 2.4 parts of deionized water.

[0030] Among them, the water-based pigment filler slurry in this embodiment mainly includes the following raw materials in parts by mass: 45.1 parts of deionized water, 10.6 parts of dispersant EFKA-4595, 0.5 parts of wetting agent BYK-331, 9 parts of graphene slurry GRF- GAC-01, 58 parts of titanium dioxide R-902, 14.5 parts of 800-mesh graphite powder, 4.6 parts of 1000-mesh aluminum tripolyphosphate, 4.6 parts of 1000-mesh zinc phosphate, 10 parts of 2000-mesh mica powder,...

Embodiment 2

[0035] The water-based epoxy anti-corrosion coating for heat exchangers in this embodiment mainly includes the following raw materials in parts by mass: 240 parts of water-based epoxy emulsion CTW-6062, 20 parts of water-based silicone emulsion MP 50E, 24 parts of amino resin CYMEL 327, 2.4 parts of catalyst CYCAT 4040, 182 parts of water-based pigment paste, 1.8 parts of defoamer BYK-022, 0.8 parts of leveling agent BYK-346, 1.2 parts of anti-flash rust agent Roybo 60, 2.4 parts of deionized water.

[0036] Among them, the water-based pigment filler slurry in this embodiment mainly includes the following raw materials in parts by mass: 45.1 parts of deionized water, 12.6 parts of dispersant BYK-190, 0.5 parts of wetting agent BYK-331, 5 parts of graphene slurry TY08W3000, 51 parts of titanium dioxide R-902, 22 parts of 800-mesh graphite powder, 4.6 parts of 1000-mesh aluminum tripolyphosphate, 2 parts of 1000-mesh zinc phosphate, 10 parts of 2000-mesh mica powder, 10 parts of ...

Embodiment 3

[0041] The water-based epoxy anti-corrosion coating for heat exchangers in this embodiment mainly includes the following raw materials in parts by mass: 240 parts of water-based epoxy emulsion CTW-6062, 12 parts of water-based silicone emulsion MPF 52E, 34 parts of amino resin CYMEL 350, 3.6 parts of catalyst BYK-450, 195.1 parts of water-based pigment paste, 1.8 parts of defoamer 901W, 0.8 parts of leveling agent RM-2020, 1.2 parts of anti-flash rust agent Roybo 60, 3 parts of deionized water.

[0042] Among them, the water-based pigment filler slurry in this embodiment mainly includes the following raw materials in parts by mass: 45.1 parts of deionized water, 10.6 parts of dispersant EFKA-4595, 0.5 parts of wetting agent BYK-331, 60 parts of titanium dioxide R-960, 14.5 parts of 800-mesh graphite powder, 4 parts of graphene slurry TY08W3000, 4.6 parts of 1000-mesh aluminum tripolyphosphate, 4.6 parts of 1000-mesh zinc phosphate, 10 parts of 2000-mesh mica powder, 10 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com