Automatic counting method for underground drill rods based on machine vision

A machine vision and automatic counting technology, applied in the fields of instrumentation, calculation, image data processing, etc., can solve the problem that the counting accuracy needs to be improved, and achieve the effect of improving the tracking speed, improving the counting accuracy, and narrowing the search range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

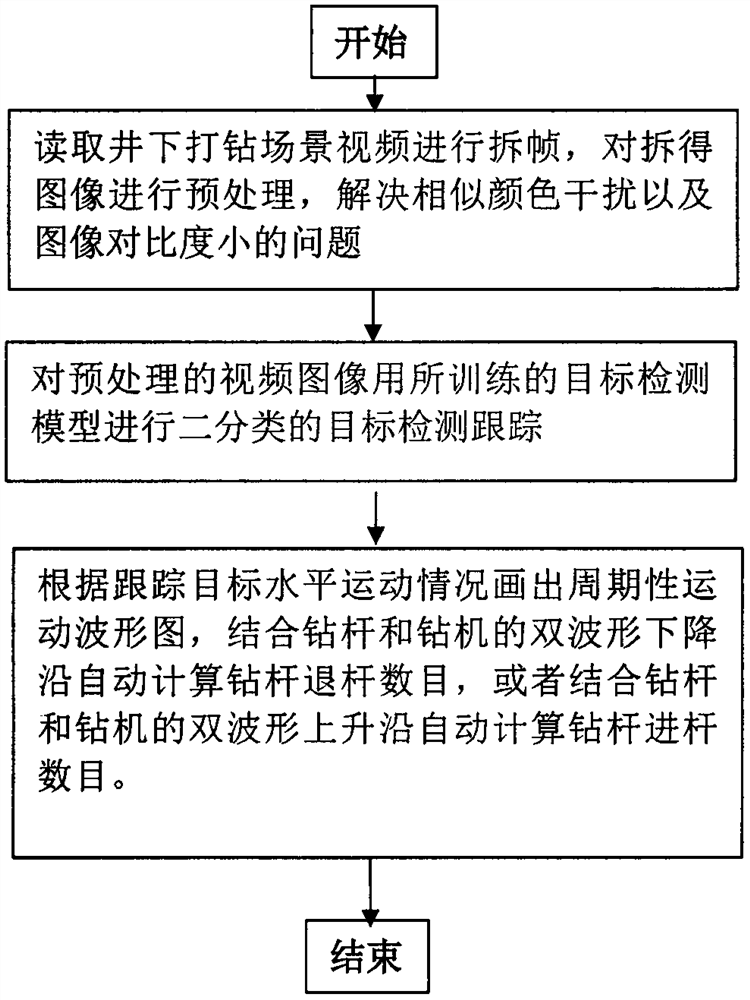

Method used

Image

Examples

Embodiment Construction

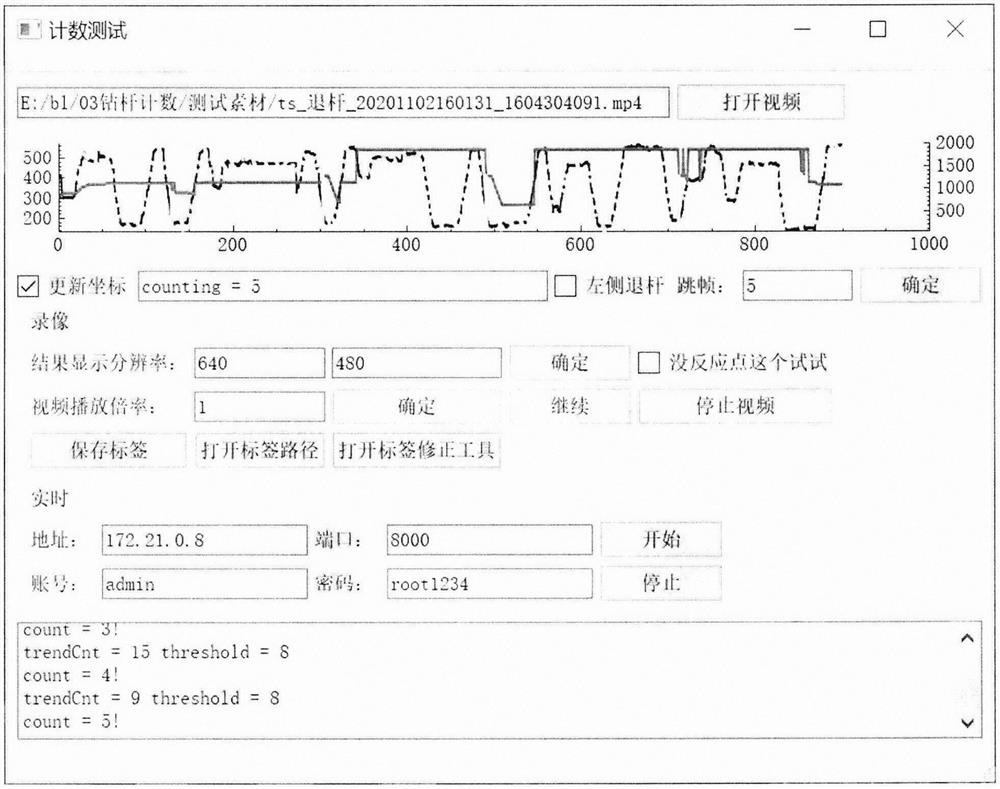

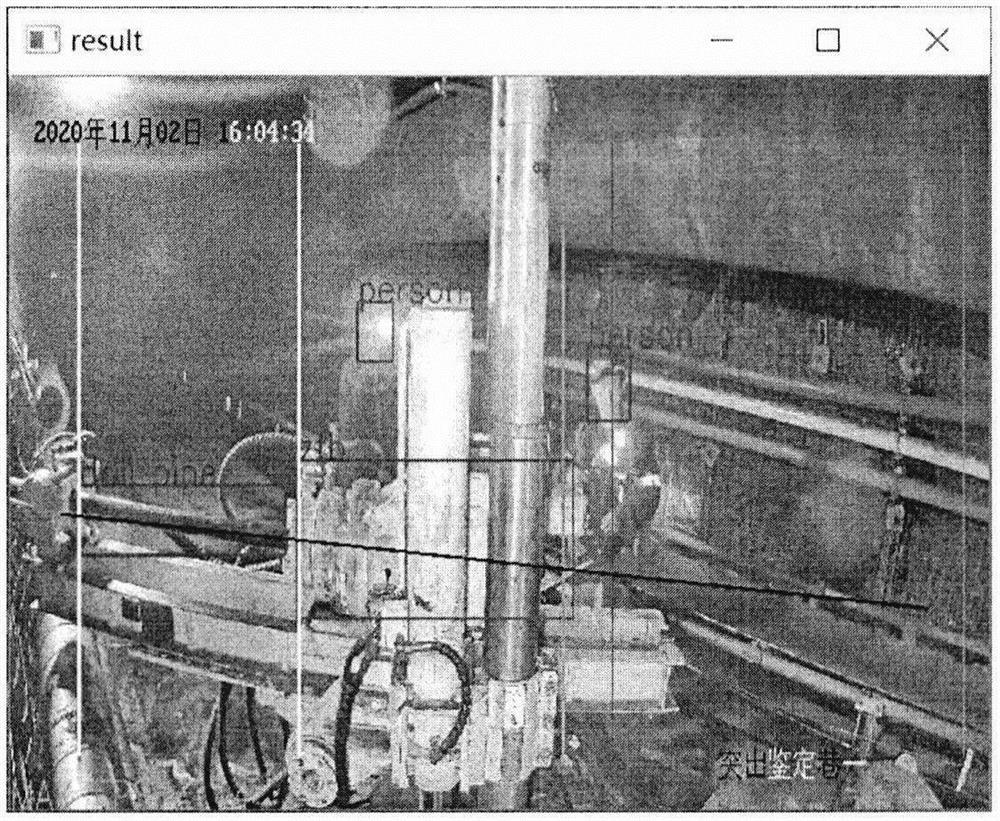

[0031] Example. Built a machine vision-based drill pipe counting software system, such as figure 2 As shown, the application relates to the software part of the system, as mentioned above, the implementation steps are as follows:

[0032] (1) Read the downhole video surveillance file, or directly pass the downhole drilling video from the camera. For the convenience of the experiment, the method of directly opening the video file is adopted. By clicking the start button, the target tracking situation can be checked, and the user can choose the result display Resolution and number of skipped frames, such as figure 2 ;Screen images of drill pipes and rig areas in the monitoring area, and remove similar color interference and noise reduction from the images through histogram equalization; after the sample image is read, it is converted into a grid of 416*416 size, and gray bars are added for To prevent distortion, the image will then be divided into three grid images (13*13, 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap