Three-dimensional porous substrate material for negative electrode of lithium metal battery as well as preparation method and application of three-dimensional porous substrate material

A lithium metal battery, three-dimensional porous technology, applied in nanotechnology for materials and surface science, battery electrodes, lithium batteries, etc., can solve the problems of battery safety and electrical cycle instability, and achieve high mechanical flexibility and excellent electrical conductivity permanent, easy-to-composite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

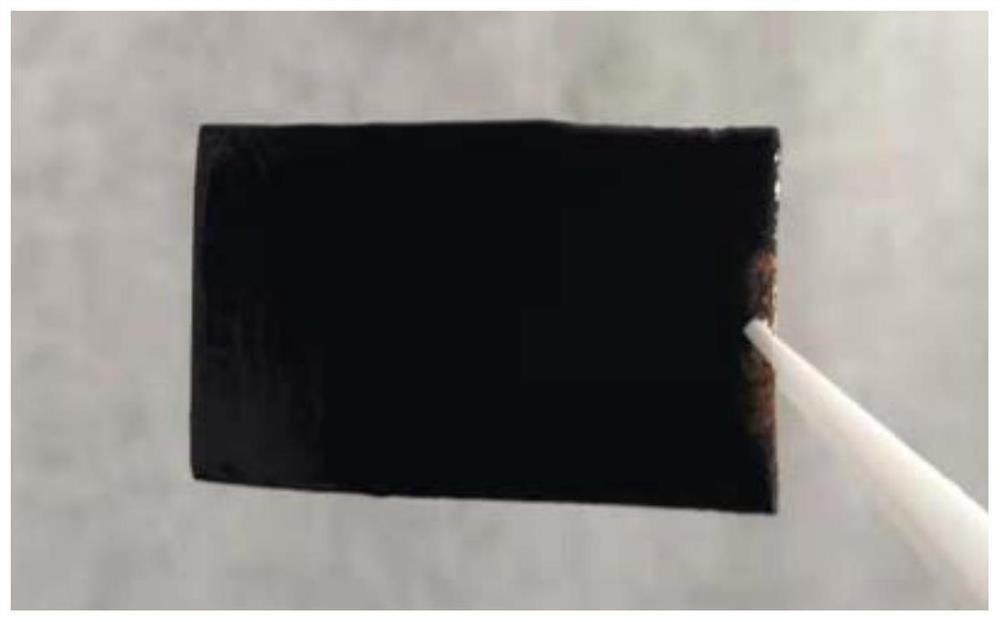

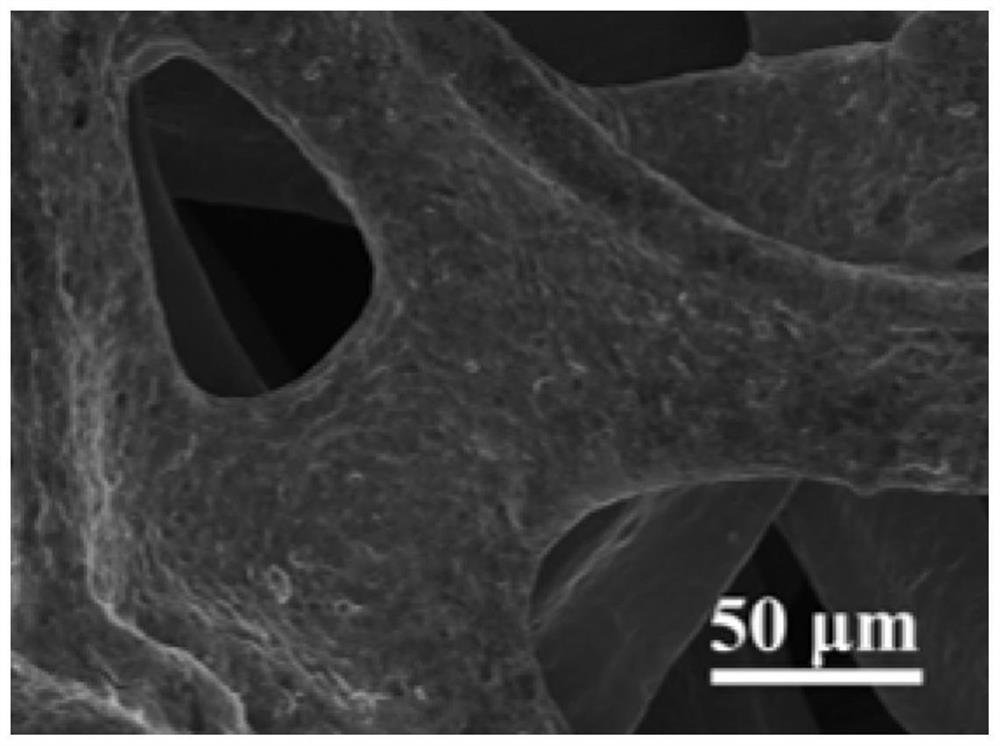

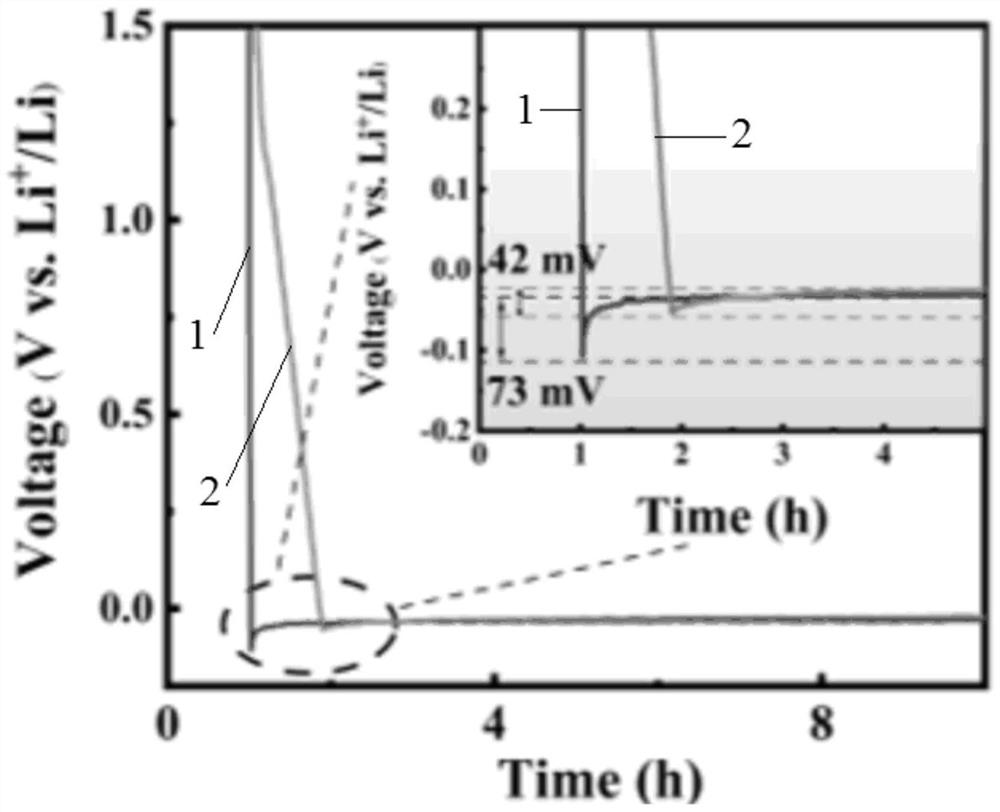

[0040] Specific Embodiment 1: In this embodiment, a three-dimensional porous base material for lithium metal battery negative electrode is composed of metal foam and metal carbon / nitride; the metal carbon / nitride is Mxenes, and the chemical formula is M n+1 x n T x , wherein M is a transition metal element, X is C or N; n=1, 2 or 3, and T is O, OH or F.

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the heat transfer coefficient of the foamed metal: > 6w / (m 2 k), mechanical strength: ≥2.5MPa, tensile strength: 5-18Kpa, pore diameter: 0.1-10mm, porosity: 60-98%, through-porosity: ≥98, bulk density: 0.5-1.5g / cm 3 , PPI (number of holes per inch): 5-130. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the metal foam is Cu foam, Ni foam, NiCrFe foam, ZnCu foam, NiCu foam, NiCrW foam or NiFe foam. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com