Motor controller, power assembly, control method and electric vehicle

A technology of a motor controller and control method, applied in motor control, AC motor control, electric vehicles, etc., can solve the problems of uneven heating of three-phase windings, small heating power, and three-phase unbalance, and achieve improved symmetry and Reliability, increase heating power, and improve the effect of heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the technical solutions provided by the embodiments of the present application, the application scenarios of the technical solutions provided in the present application are firstly introduced below.

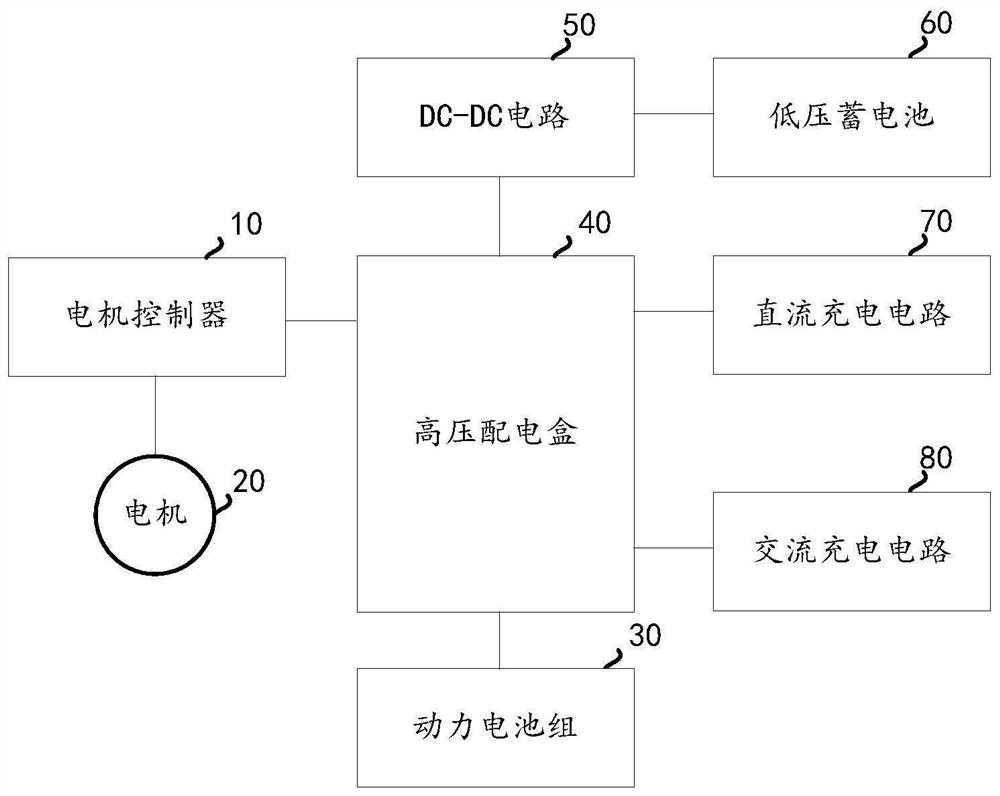

[0059] see figure 1 , which is a schematic diagram of a schematic electrical system of an electric vehicle provided in an embodiment of the present application.

[0060] The electrical system of the illustrated electric vehicle mainly includes a motor controller 10 , a motor 20 , a power battery pack 30 , a high-voltage power distribution box 40 , a DC-DC circuit 50 , a low-voltage battery 60 , a DC charging circuit 70 and an AC charging circuit 80 .

[0061] Among them, the power battery pack 30 is used to provide high-voltage direct current, and a part of the high-voltage direct current is converted into alternating current through the high-voltage power distribution box 40 and the motor controller 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com