Compound feed for forcibly moulting laying hens and preparation method of compound feed

A technology of forced molt and compound feed, which is applied in the field of animal nutrition and feed science, can solve the problem of nutritional requirements beyond the pursuit of nutrient concentration, and achieve the goals of promoting animal growth and production efficiency, improving the quality of livestock and poultry products, and improving the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

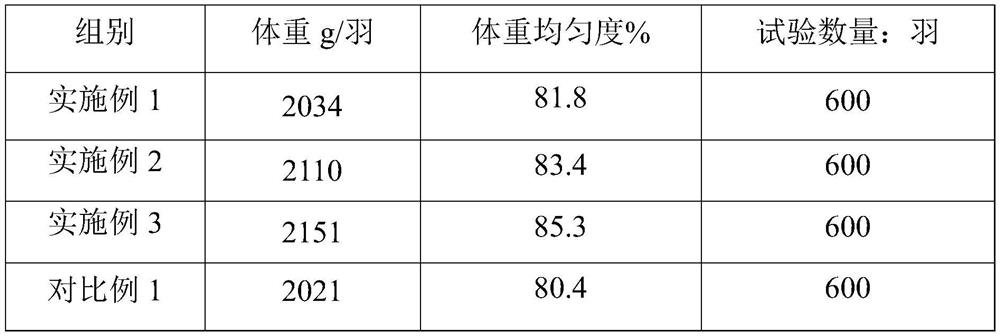

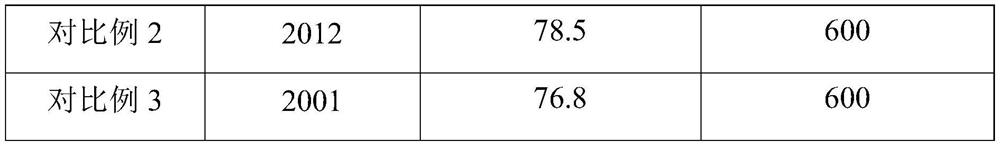

Examples

Embodiment 1

[0040] A compound feed for forced moulting laying hens, comprising the following raw materials in parts by mass:

[0041] 50 parts of corn, 15 parts of soybean meal, 2 parts of sesame meal, 3 parts of corn gluten powder, 1 part of vegetable cake, 2 parts of licorice protein, 2 parts of red date powder, 1 part of Eucommia leaf powder, 7 parts of stone powder, 0.5 part of oil, 0.2 part of salt 0.6 parts of amino acids, 0.5 parts of calcium hydrogen phosphate, 0.2 parts of multivitamins, 0.1 parts of compound trace elements, 0.06 parts of compound enzyme preparations, 0.1 parts of baking soda, 2 parts of Chinese herbal compound packs, and 0.2 parts of probiotic preparations.

[0042] The steps that preparation method comprises are as follows:

[0043] S1. Amino acids, compound enzyme preparations, compound vitamins and compound trace elements are prepared separately for use;

[0044] S2. Weighing cereals, soybean meal, sesame meal, corn gluten powder, licorice protein, red date ...

Embodiment 2

[0051] A compound feed for forced moulting laying hens, comprising the following raw materials in parts by mass:

[0052] Accurately weigh 55 parts of corn, 18 parts of soybean meal, 4 parts of sesame meal, 5 parts of corn gluten powder, 2 parts of vegetable cake, 3 parts of licorice protein, 4 parts of red date powder, 3 parts of Eucommia leaf powder, 8 parts of stone powder, and 0.8 parts of oil , 0.25 parts of table salt, 0.8 parts of amino acids, 0.8 parts of calcium hydrogen phosphate, 0.2 parts of multivitamins, 0.2 parts of compound trace elements, 0.08 parts of compound enzyme preparations, 0.2 parts of baking soda, 3 parts of Chinese herbal medicine compound packs, and 0.3 parts of probiotic preparations.

[0053] The steps that preparation method comprises are as follows:

[0054] S1. Amino acids, compound enzyme preparations, compound vitamins and compound trace elements are prepared separately for use;

[0055] S2. Weighing cereals, soybean meal, sesame meal, corn...

Embodiment 3

[0062] A compound feed for forced moulting laying hens, comprising the following raw materials in parts by mass:

[0063] Accurately weigh 60 parts of corn, 25 parts of soybean meal, 5 parts of sesame meal, 3 parts of corn gluten powder, 3 parts of vegetable cake, 5 parts of licorice protein, 6 parts of red date powder, 5 parts of Eucommia leaf powder, 9 parts of stone powder, and 1.0 part of oil , 0.3 parts of table salt, 0.9 parts of amino acids, 1.2 parts of calcium hydrogen phosphate, 0.3 parts of multivitamins, 0.3 parts of compound trace elements, 0.1 parts of compound enzyme preparations, 0.3 parts of baking soda, 5 parts of Chinese herbal medicine compound packs, and 0.5 parts of probiotic preparations.

[0064] The steps that preparation method comprises are as follows:

[0065] S1. Amino acids, compound enzyme preparations, compound vitamins and compound trace elements are prepared separately for use;

[0066] S2. Weighing cereals, soybean meal, sesame meal, corn gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com