Wafer processing device and method

A processing device and processing method technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of inability to remove flue gas, loss of wafer yield, etc., to prevent the equipment from becoming larger and expand the manufacturing space , The effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

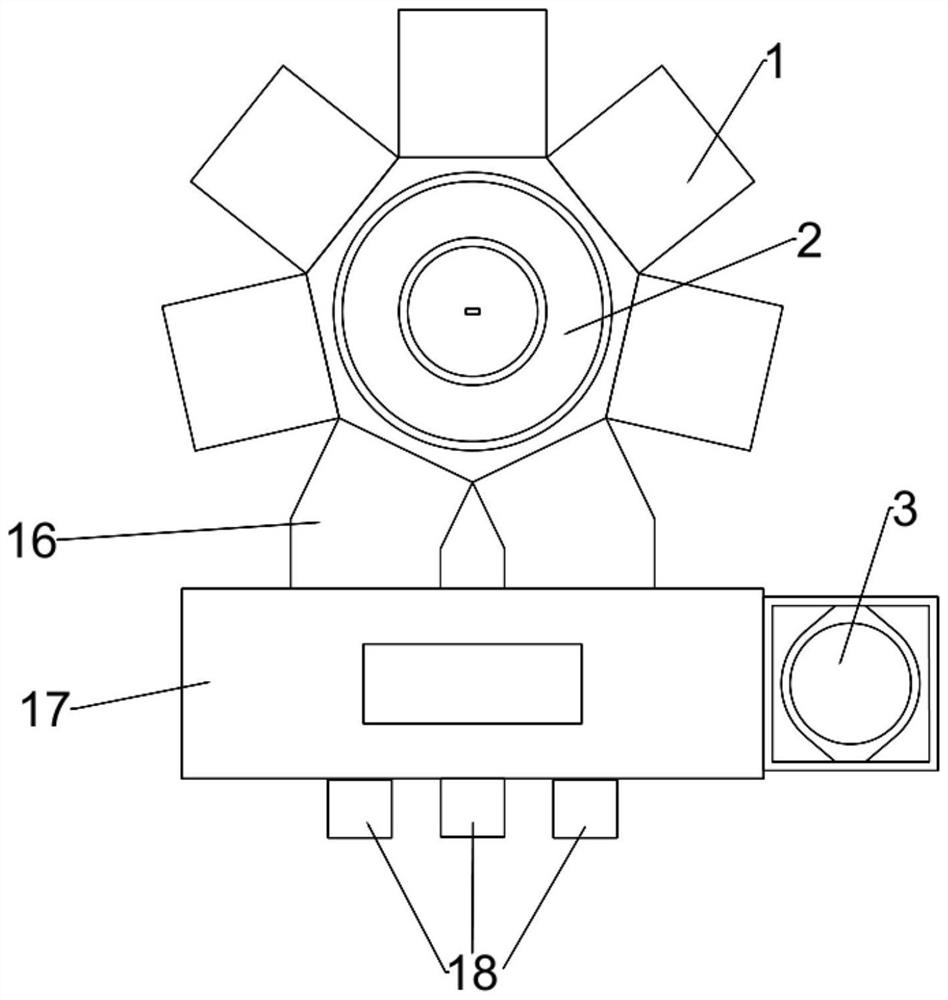

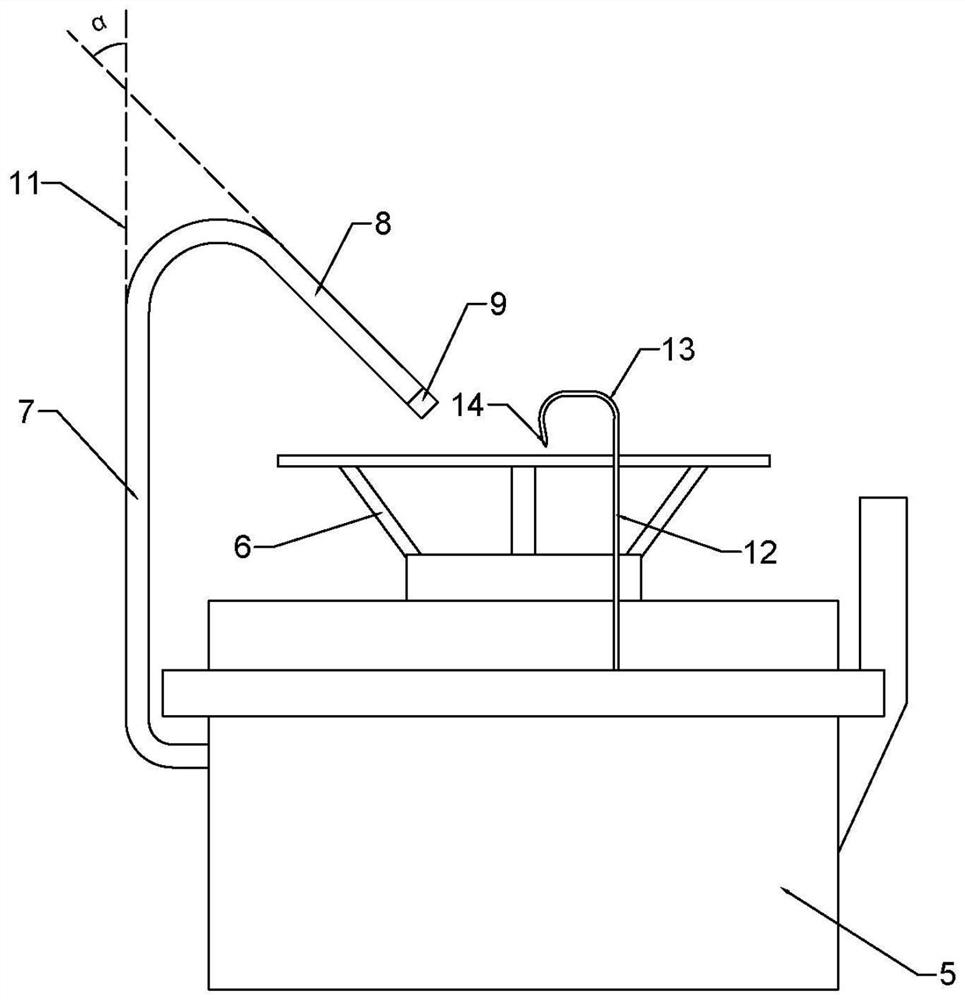

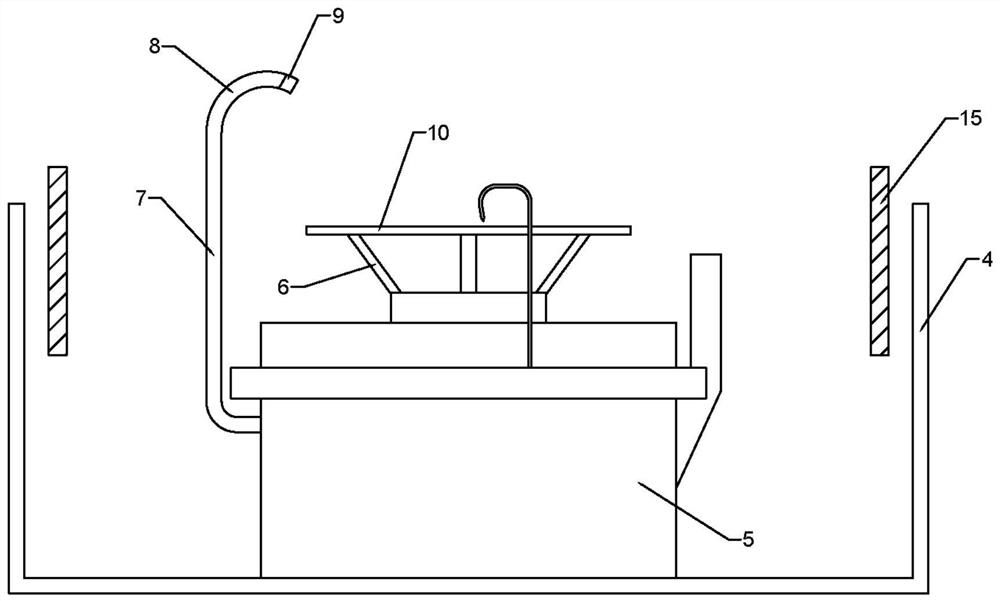

[0038] A specific embodiment of the present invention discloses a wafer processing device, such as figure 1 shown. The wafer processing apparatus includes a process chamber 1 , a transfer chamber 2 , a cleaning system 3 , a pre-evacuation chamber 16 , an atmospheric transfer chamber 17 and a rack 18 . Process chambers may include etch chambers or deposition chambers or injection chambers. The transfer chamber 2 is provided with a transfer robot, and the transfer of the wafer between the process chamber 1 and the transfer chamber 2 and between the transfer chamber 2 and the cleaning system 3 is completed by the transfer robot.

[0039] In a possible implementation manner, the cleaning system 3 is set in the wafer processing device, so that the wafers processed by the etching chamber, the deposition chamber or the injection chamber can directly enter the cleaning system 3 for cleaning.

[0040] In order to prevent the volume of the cleaning system 3 from becoming larger after ...

Embodiment 2

[0055] Another embodiment of the present invention discloses a wafer processing method, which includes the transfer robot in the transfer chamber picking up the wafer and placing it in the process chamber, and after the wafer is processed, the transfer robot picks up the wafer again and places it in the cleaning The system is cleaned and dried.

[0056] Because the wafer manufacturing process usually requires multiple processes, there are also multiple processes that generate fumes, such as etching processes, deposition processes, and implant processes. In the wafer processing method of the present invention, after each fume-generating process is completed, the wafer is immediately sent to the cleaning system for cleaning and drying without any delay, so that the fume will not flow on the wafer. The surface is solidified, so that the removal of smoke is more thorough, and effectively prevents yield loss.

[0057] The etching process is taken as an example below to describe th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com