Preparation method of high-precision gradient pore filter element

A gradient porosity and high-precision technology, applied in the field of powder metallurgy, can solve the problems of poor bonding between the membrane layer and the tube body, complex manufacturing process, difficult precision control, etc., and achieve the effect of improving filtration efficiency, simple process and high filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

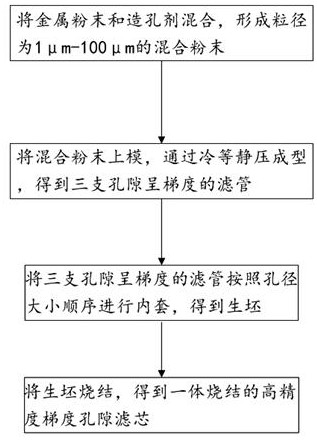

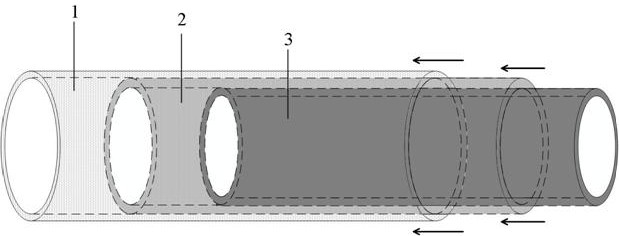

[0040] like figure 1 As shown, the present invention provides a preparation method of a high-precision gradient pore filter element, comprising:

[0041] Step 1. Mix the metal powder and the pore-forming agent to form a mixed powder with a particle size of 1 μm-100 μm. The specific preparation of the mixed powder includes the following steps:

[0042] Step 101, the raw material of the outermost large-pore filter element is the first mixed powder mixed with metal powder and pore-forming agent, wherein the mass fraction of the pore-forming agent in the first mixed powder is 30w%-50w%; The raw material is the second mixed powder mixed with metal powder and pore-forming agent, wherein the mass fraction of the pore-forming agent in the second mixed powder is 20w%-40w%; the raw material of the innermost small-pore filter element is mixed with metal powder and pore-forming agent The third mixed powder, wherein the mass fraction of the pore-forming agent in the third mixed powder is ...

Embodiment 1

[0060] The following mixed powder raw materials select nickel carbonyl powder with a particle size of 5 μm, adjust the addition amount of urea to carry out the gradient change of pores, and the preparation method is as follows:

[0061] Step 1: Preparation of mixed powder raw materials: The raw materials are 5μm carbonyl nickel powder and urea, wherein the addition amount of urea in the first filter tube of the outermost layer is 30t%; the addition amount of urea in the second filter tube of the middle layer is 20w%. The amount of urea added in the third filter tube of the layer is 10w%. The carbonyl nickel powder and urea were respectively mixed with deionized water to make a mixed solution and canned, and then placed on a roller ball mill and mixed for 3 hours to make the powder mixed evenly. After the mixing is completed, it is dried in an electric furnace, and the powder is stirred during the drying process until the powder is completely dried. Then, the mixed dry materia...

Embodiment 2

[0067] The following mixed powder raw materials select carbonyl nickel powder with particle sizes of 5 μm, 10 μm and 15 μm, adjust the addition amount of urea to 15%, and carry out gradient change of pores. The preparation method is as follows:

[0068] Step 1: Preparation of mixed powder raw materials: As the raw material of the first filter tube in the outermost layer, take 15 μm nickel carbonyl powder and add 15w% urea; as the raw material of the second filter tube in the middle layer, take 10 μm nickel carbonyl powder and add 15w% urea. The raw material of the three filter tubes is 5μm nickel carbonyl powder and 15w% urea is added. The mixing and drying method was the same as that of Example 1, and the mixed powder with a particle size of 50 μm was sieved with a screen. The sieved mixed powder was put into the ball mill and mixed for 3 hours. After the mixing was completed, the subsequent pressing was waited for. Prepare the mixed powder raw materials of the three filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com