Red mud-based soil stabilizer and preparation method thereof

A technology of soil stabilizer and red mud, which is applied in chemical instruments and methods, soil conditioning materials, solid waste management, etc., can solve the problems of pollution, high storage cost, and low utilization rate of red mud, and achieve excellent comprehensive performance and enhanced Large utilization rate and far-reaching practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

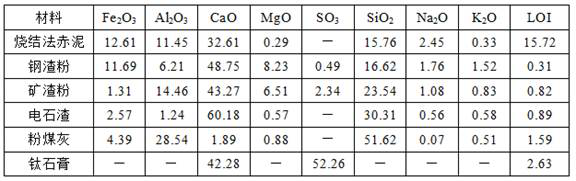

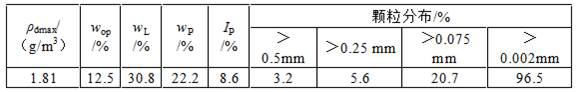

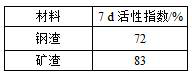

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of 1# red mud-based soil stabilizer

[0033] Raw material ratio: red mud 70%, enhancer (carbide slag) 25%, activator (sodium hydroxide) 5%;

[0034] Preparation method: firstly, the red mud and carbide slag are dried to a moisture content of less than 1%, mixed with sodium hydroxide, and then sent to a pulverizer to grind to a particle size of less than 300 mesh to obtain a finished product of 1# red mud-based soil curing agent .

[0035] Add the prepared 1# curing agent to the soil at a dosage of 4%, measure the optimum moisture content, add water at the optimum moisture content of the mixture, mix and compact it uniformly, and maintain it according to the test method. , test the properties of the solidified soil, as shown in Table 4.

Embodiment 2

[0036] Example 2 Preparation of 2# red mud-based soil stabilizer

[0037] Raw material ratio: red mud 50%, enhancer (carbide slag: steel slag powder = 2:1) 40%, activator (titanium gypsum) 10%;

[0038] Preparation method: first, coarsely grind red mud, carbide slag, steel slag powder and titanium gypsum into particles with a particle size of less than 5 mm, dry to a moisture content of less than 1%, and then send the mixture prepared in proportion to a pulverizer Grind to a particle size of less than 300 mesh to obtain a finished product of 2# red mud-based soil curing agent.

[0039] Add the prepared 2# curing agent to the soil according to the mixing amount of 4%, 6% and 8% respectively, measure the optimum moisture content, add water with the optimum moisture content of the mixture, mix and compact it uniformly, according to the test method After curing, after the maturity period, the properties of the solidified soil were tested, as shown in Table 4.

Embodiment 3

[0040] Example 3 Preparation of 3# red mud-based soil curing agent

[0041] Raw material ratio: red mud 30%, enhancer (P.O 42.5 cement) 60%, activator (sodium silicate) 10%;

[0042] Preparation method: dry the red mud to a moisture content of less than 1%, then send the red mud, P.O 42.5 cement and sodium silicate mixture prepared in proportion to a pulverizer and grind to a particle size of less than 300 mesh to obtain 3# Red mud-based soil stabilizer product.

[0043] Add the prepared 3# solidifying agent into the soil according to the mixing amount of 4%, measure the optimum moisture content, add water at the optimum moisture content of the mixture, mix and compact it uniformly, and maintain it according to the test method. , test the properties of the solidified soil, as shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com