Oxygen-increasing phosphorus-free concentrated washing liquid and preparation method thereof

A technology of concentrated washing liquid and solution, applied in the field of detergent, can solve the problems of not being able to adapt to fast production, slow dissolution speed, etc., achieve the effect of saving packaging and transportation, and enhancing the effect of decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

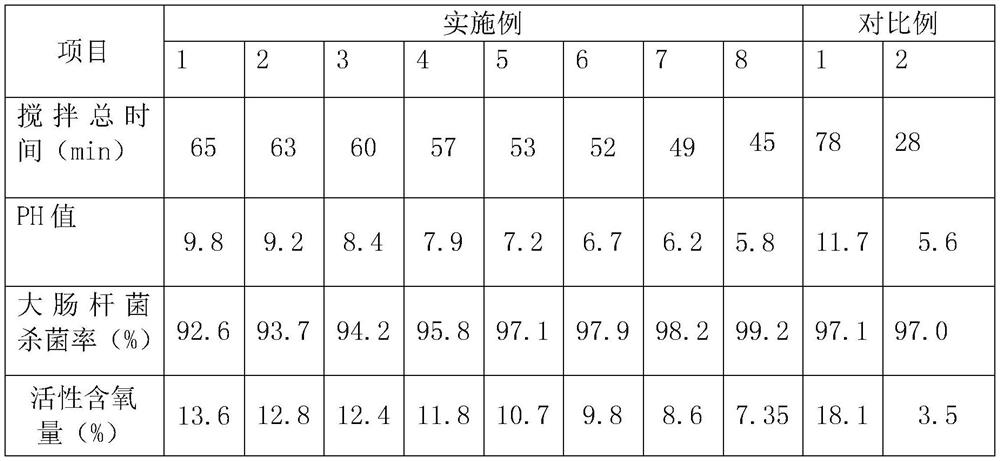

Examples

Embodiment 1

[0037] This embodiment provides an oxygen-enhanced, phosphorus-free concentrated washing solution, which includes the following raw materials in parts by weight: 5 parts of sodium percarbonate, 3 parts of potassium carbonate, 2 parts of citric acid monohydrate, 30 parts of active substances, 0.2 parts of essence and paraben 0.1 part of gold ethyl ester and the rest are water.

[0038] The active substance is prepared from the following components in parts by weight: 10 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 15 parts of linear alkyl benzene sulfonate sodium, 3 parts of sodium lauryl sulfate, and 2 parts of cocoamide.

[0039] The preparation method of oxygen-enhanced phosphorus-free concentrated washing solution comprises the steps:

[0040] S1: respectively called quasi-sodium percarbonate, potassium carbonate, citric acid and water;

[0041] S2: turn on the mixer, adjust the rotational speed to 13 revolutions per minute, add 7KG of water to the mixer, a...

Embodiment 2

[0049] This embodiment provides an oxygen-enhanced and phosphorus-free concentrated washing solution, which includes the following raw materials by weight: 5 parts of sodium percarbonate, 3 parts of potassium carbonate, 3 parts of citric acid monohydrate, 31 parts of active substances, 0.2 parts of essence and paraben 0.1 part of gold ethyl ester and the rest are water.

[0050] The active substance is prepared from the following components in parts by weight: 10 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 15 parts of linear alkyl benzene sulfonate sodium, 3 parts of sodium lauryl sulfate, and 2 parts of cocoamide.

[0051] The preparation method of oxygen-enhanced phosphorus-free concentrated washing solution comprises the steps:

[0052] S1: respectively called quasi-sodium percarbonate, potassium carbonate, citric acid and water;

[0053] S2: turn on the mixer, adjust the rotational speed to 13 revolutions per minute, add 7KG of water to the mixer, add cit...

Embodiment 3

[0061] This embodiment provides an oxygen-enhanced, phosphorus-free concentrated washing solution, comprising the following raw materials in parts by weight: 5 parts of sodium percarbonate, 3 parts of potassium carbonate, 4 parts of citric acid monohydrate, 32 parts of active substances, 0.2 parts of essence and paraben 0.1 part of gold ethyl ester and the rest are water.

[0062] The active substance is prepared from the following components in parts by weight: 10 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 15 parts of linear alkyl benzene sulfonate sodium, 3 parts of sodium lauryl sulfate, and 2 parts of cocoamide.

[0063] The preparation method of oxygen-enhanced phosphorus-free concentrated washing solution comprises the steps:

[0064] S1: respectively called quasi-sodium percarbonate, potassium carbonate, citric acid and water;

[0065] S2: turn on the mixer, adjust the rotational speed to 13 revolutions per minute, add 7KG of water to the mixer, add c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com