Device for preparing light-cured water-carrying capsule and preparation method of light-cured water-carrying capsule

A light-curing device and light-curing technology, applied in microcapsule preparations, microsphere preparation, etc., can solve the problems of incomplete curing, uncontrollable droplet falling speed, and difficult to control the sphericity of water-carrying capsules, and improve concentricity. degree and sphericity, the effect of high water-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

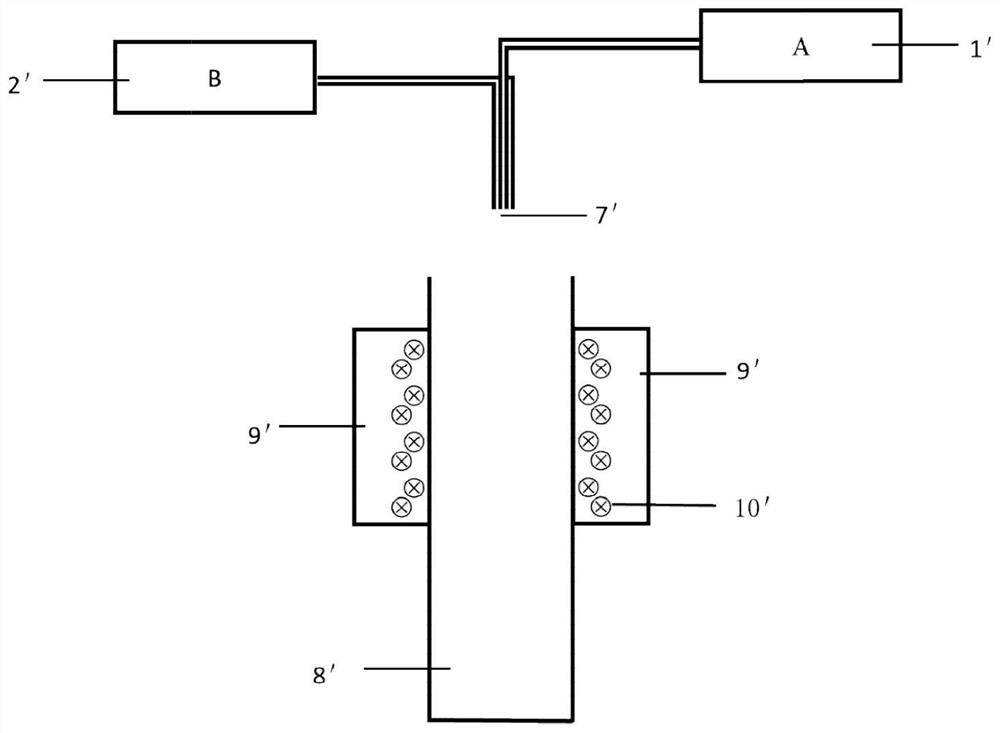

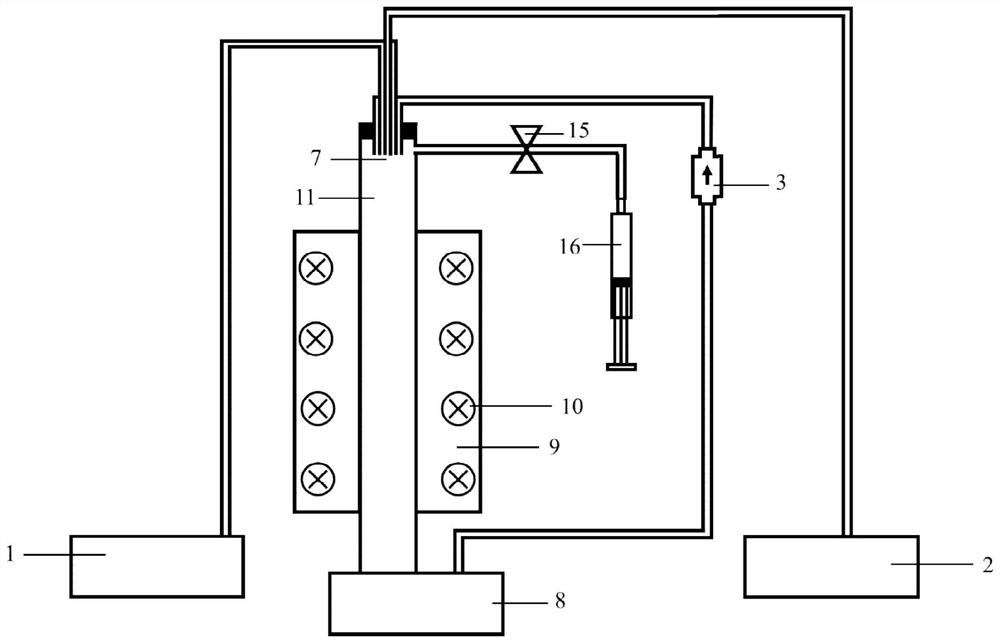

[0070] The water-carrying capsules were prepared by the millifluidic method, and the millifluidic method was image 3 shown.

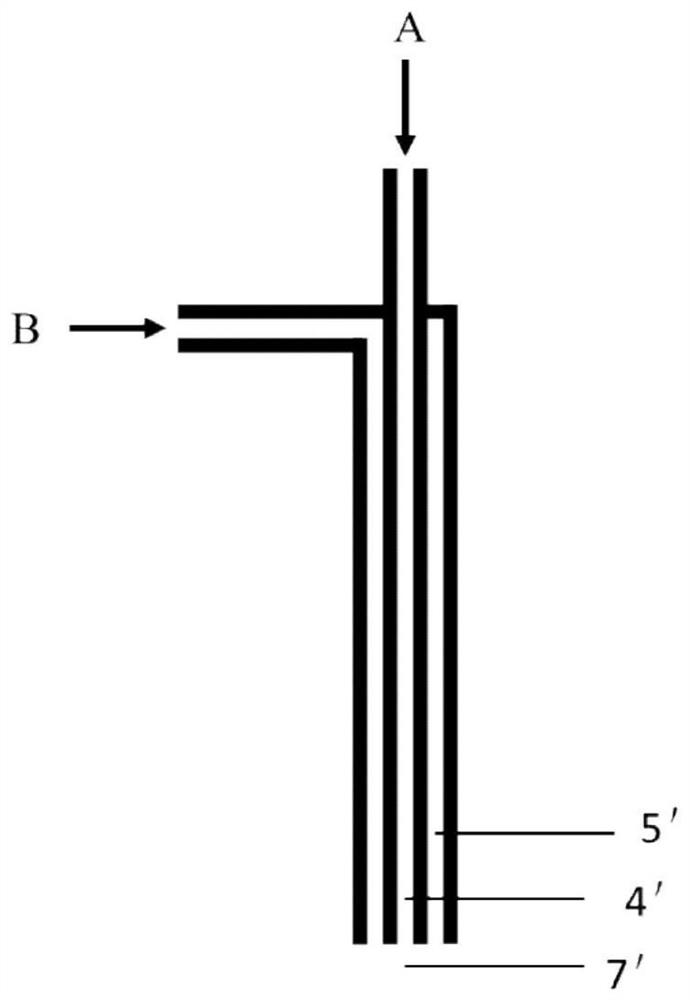

[0071] Using the aqueous solution of 1wt% Tween 80 as the inner phase, pumped by the inner phase pump 1, the flow rate is set to 0.20mL / min, and squeezed from the inner layer outlet 4 (inner diameter 0.67mm, outer diameter 1.07mm) of the three-layer coaxial needle 7 out;

[0072] 82% urethane acrylate prepolymer, 15% hydroxyethyl methacrylate, 3% diphenyl-(2,4,6-trimethylbenzoyl) oxyphosphorus as the mesophase (mesophase viscosity 1000mPa· s, 25°C), pumped by the mesophase pump 2, the flow rate is set to 0.04mL / min, and extruded from the middle outlet 5 (inner diameter 1.6mm, outer diameter 2.1mm) of the three-layer coaxial needle; with 3wt% polyethylene The alcohol solution (viscosity 100mPa·s) is the external phase, pumped by the external phase pump 3, the flow rate is set to 8mL / min, inhaled from the collector 8, from the three-layer coaxial needl...

Embodiment 2

[0075] The water-carrying capsules were prepared by the millifluidic method, and the millifluidic method was Figure 3-5 shown.

[0076] Take water as the inner phase, pump through the inner phase pump 1, the flow rate is set to 0.20mL / min, and extrude from the inner layer outlet 4 (inner diameter 0.67mm, outer diameter 1.07mm) of the three-layer coaxial needle 7; with 97% polyurethane Acrylate prepolymer (viscosity 14000mPa s, 25℃), 3% diphenyl-(2,4,6-trimethylbenzoyl) oxyphosphorus as mesophase, pumped by mesophase pump 2, flow rate Set to 0.04mL / min, extrude from the middle outlet 5 of the three-layer coaxial needle (inner diameter 1.6mm, outer diameter 2.1mm); take 3wt% polyvinyl alcohol solution (viscosity 100mPa·s) as the external phase, through the external phase pump 3 Pumping, the flow rate is set to 8 mL / min, sucked from the collector 8, and extruded from the outer layer outlet 6 of the three-layer coaxial needle (inner diameter 3mm, outer diameter 3.5mm). The thre...

Embodiment 3

[0078] Same as Example 1, the difference is that 95wt% epoxy acrylate prepolymer (viscosity 10000mPa s, 25°C), 5wt% diphenyl-(2,4,6-trimethylbenzoyl) ) oxyphosphorus as an intermediate phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com