A kind of polishing method of gallium antimonide single wafer

A single-wafer, gallium antimonide technology, applied to polishing compositions containing abrasives, grinding/polishing equipment, grinding/polishing safety devices, etc. and other problems, to achieve the effect of low surface roughness, simple process and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

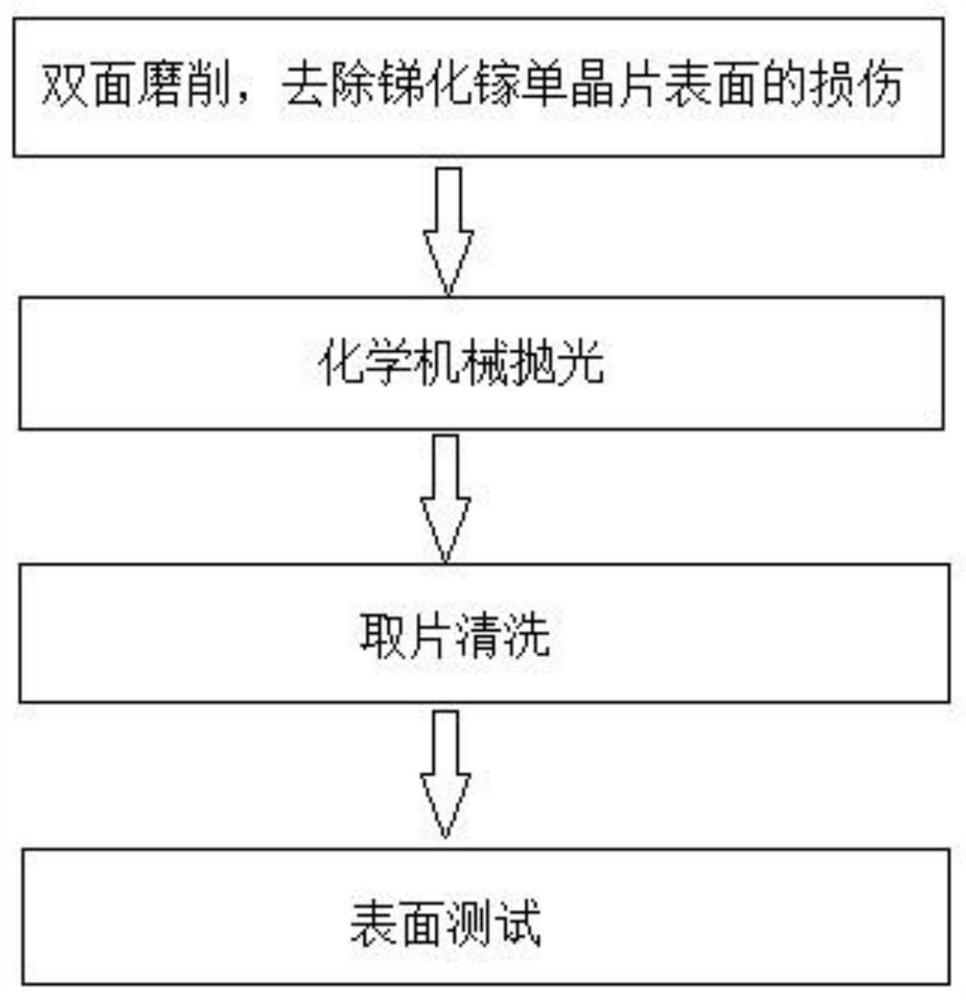

Method used

Image

Examples

Embodiment 1

[0033] (1) Remove the damage on the surface of the gallium antimonide single wafer; use quartz wax to evenly paste the gallium antimonide single wafer on the ceramic carrier and use natural curing, wipe off the excess quartz wax with alcohol, and then pass it through a grinding machine. Use 6000 mesh grinding wheel, 4000 rpm for double-sided grinding, and the removal amount is controlled to 40um.

[0034] (2) Chemical mechanical polishing: The polishing cloth is made of black synthetic leather, the velvet length of the polishing cloth is 225um, and the aperture of the polishing cloth is 50-90um.

[0035] The polishing liquid is made by mixing the following components according to the mass percentage: 50nm SiO 2 Suspended abrasive 1.2%, sodium dichloroisocyanurate 0.5%, sodium bicarbonate 2%, sodium pyrophosphate 0.25%, sodium benzenesulfonate 0.25%, and the balance is deionized water.

[0036] The technological parameters of the polishing process are as follows: the polishing...

Embodiment 2

[0040] The polishing process of the gallium antimonide single wafer provided in this embodiment is basically the same as the above-mentioned embodiment 1, except that the pile length of the polishing cloth is 350um, and the aperture diameter of the polishing cloth is 30-70um.

[0041] The polishing liquid is made by mixing the following components according to the mass percentage: 50nm SiO 2 Suspended abrasive 1.2%, sodium dichloroisocyanurate 0.25%, sodium bicarbonate 2%, sodium pyrophosphate 0.25%, sodium benzenesulfonate 0.25%, and the balance is deionized water.

[0042] The technological parameters of the polishing process are as follows: the polishing pressure is 200g / cm 2 , the polishing speed is 40-100 rpm, the polishing liquid flow is 30 mL / min, and the polishing time is 50 min.

Embodiment 3

[0044] The polishing process of the gallium antimonide single wafer provided in this embodiment is basically the same as that of the above-mentioned embodiment 1, except that the pile length of the polishing cloth is 225um, and the diameter of the polishing cloth is 50-90um.

[0045] The polishing liquid is made by mixing the following components according to the mass percentage: 50nm SiO 2 Suspended abrasive 1.2%, sodium dichloroisocyanurate 0.25%, sodium bicarbonate 2%, sodium pyrophosphate 0.25%, sodium benzenesulfonate 0.25%, and the balance is deionized water.

[0046] The technological parameters of the polishing process are as follows: the polishing pressure is 200g / cm 2 , the polishing speed is 70 rpm, the polishing liquid flow is 30 mL / min, and the polishing time is 50 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com