Method for extracting and separating dimethylformamide in wastewater by adopting eutectic solvent

A technology of dimethylformamide and low eutectic solvent is applied in the field of chemical waste solvent treatment and recovery, which can solve the problems of large pollution, high toxicity and easy volatility of extractants, and achieves simple and easy process operation, low toxicity, and reduced The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

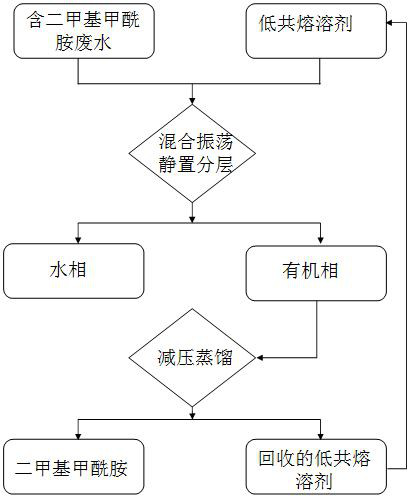

[0027] The flow chart of the present invention is as follows figure 1 shown.

[0028] Prepare 10 g of a deep eutectic solvent containing 70% by mass of caprylic acid and 30% by mass of lauric acid, and prepare 10 g of simulated wastewater containing 30% by mass of dimethylformamide, mix the two phases and perform shaking extraction at 30 °C 2h, after the extraction, the layers were separated by standing. Take the organic phase and the aqueous phase to detect the concentration of dimethylformamide, the results show that the distribution coefficient of dimethylformamide is 0.571, and the selectivity coefficient is 11.6.

[0029] The organic phase after extraction was placed in a rotary evaporator, distilled at 120° C. and a vacuum of 97 kPa for 2 h, and fractions were collected under this condition. The DMF content in the fraction separated by vacuum distillation is 87wt%, and the rest is composed of 13wt% caprylic acid and a trace amount of lauric acid. The fractions collect...

Embodiment 2

[0031] Prepare 10 g of a deep eutectic solvent containing 90% by mass of caprylic acid and 10% by mass of lauric acid, and prepare 10 g of simulated wastewater containing 20% by mass of dimethylformamide. Mix the two phases and perform shaking extraction at 30 °C. 2h, after the extraction, the layers were separated by standing. The organic phase and the aqueous phase were taken to detect the concentration of dimethylformamide. The results showed that the distribution coefficient of dimethylformamide was 0.627 and the selectivity coefficient was 9.8.

[0032] The organic phase after extraction was placed in a rotary evaporator, distilled at 120° C. and a vacuum of 97 kPa for 2 h, and fractions were collected under this condition. The DMF content in the fraction separated by vacuum distillation is 85wt%, and the rest is composed of 15wt% caprylic acid and a trace amount of lauric acid. The fractions collected by the first vacuum distillation were placed in a rotary evaporator...

Embodiment 3

[0034] Prepare 10 g of a deep eutectic solvent containing 70% by mass of caprylic acid and 30% by mass of lauric acid, select 10 g of simulated wastewater containing 20% by mass of dimethylformamide, mix the two phases and perform shaking extraction at 15 °C 2h, after the extraction, the layers were separated by standing. The organic phase and the aqueous phase were taken to detect the concentration of dimethylformamide. The results showed that the distribution coefficient of dimethylformamide was 0.521, and the selectivity coefficient was 10.5.

[0035] The organic phase after extraction was placed in a rotary evaporator, distilled at 120° C. and a vacuum of 97 kPa for 2 h, and fractions were collected under this condition. The DMF content in the fraction separated by vacuum distillation is 85wt%, and the rest is composed of 15wt% caprylic acid and a trace amount of lauric acid. The fractions collected by the first vacuum distillation were placed in a rotary evaporator, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com