New energy automobile part surface electrophoresis device treatment integrated device

A technology for new energy vehicles and electrophoresis devices, applied in electrophoretic plating, electrolytic coatings, coatings, etc., to achieve the effect of saving resources and improving convenience in painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

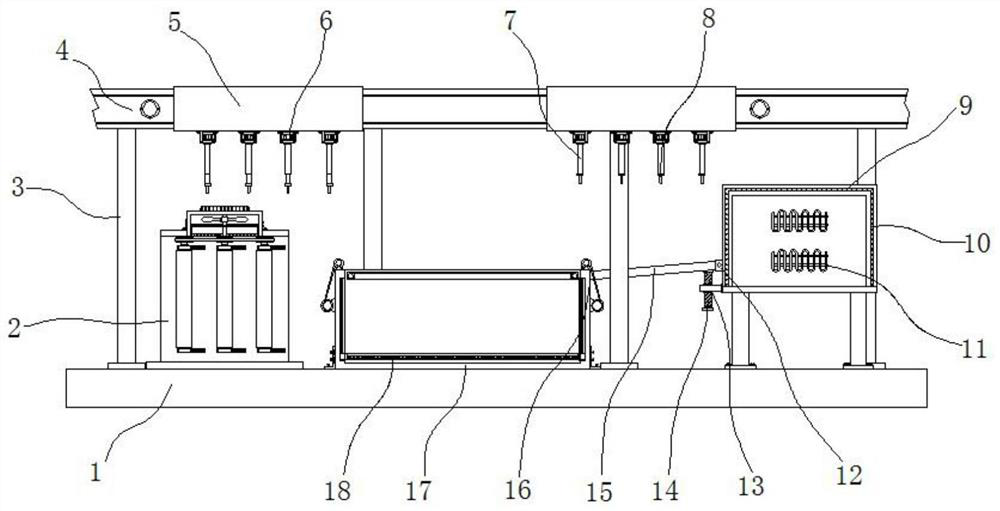

[0029] Example 1: see Figure 1-5 , an integrated device for surface electrophoresis treatment of new energy auto parts, including a base 1, a pillar 3, a drying box 9 and a paint pool 17, one side of the top of the base 1 is provided with a cleaning mechanism 2, and two ends of the top of the base 1 are provided. There are a plurality of groups of pillars 3 fixedly connected respectively, and a transmission mechanism 4 is fixedly connected between the top ends of the pillars 3. The transmission mechanism 4 is movably connected with a plurality of groups of boxes 5, and the bottom end of the box 5 is fixedly connected with four groups of hydraulic cylinders 6. The output end of the hydraulic cylinder 6 is fixedly connected with a telescopic rod 7, and the bottom end of the telescopic rod 7 is fixedly connected with a hook 8, the other side of the top of the base 1 is fixedly connected with a drying box 9, and the outer side of the drying box 9 is fixedly connected. An insulati...

Embodiment 2

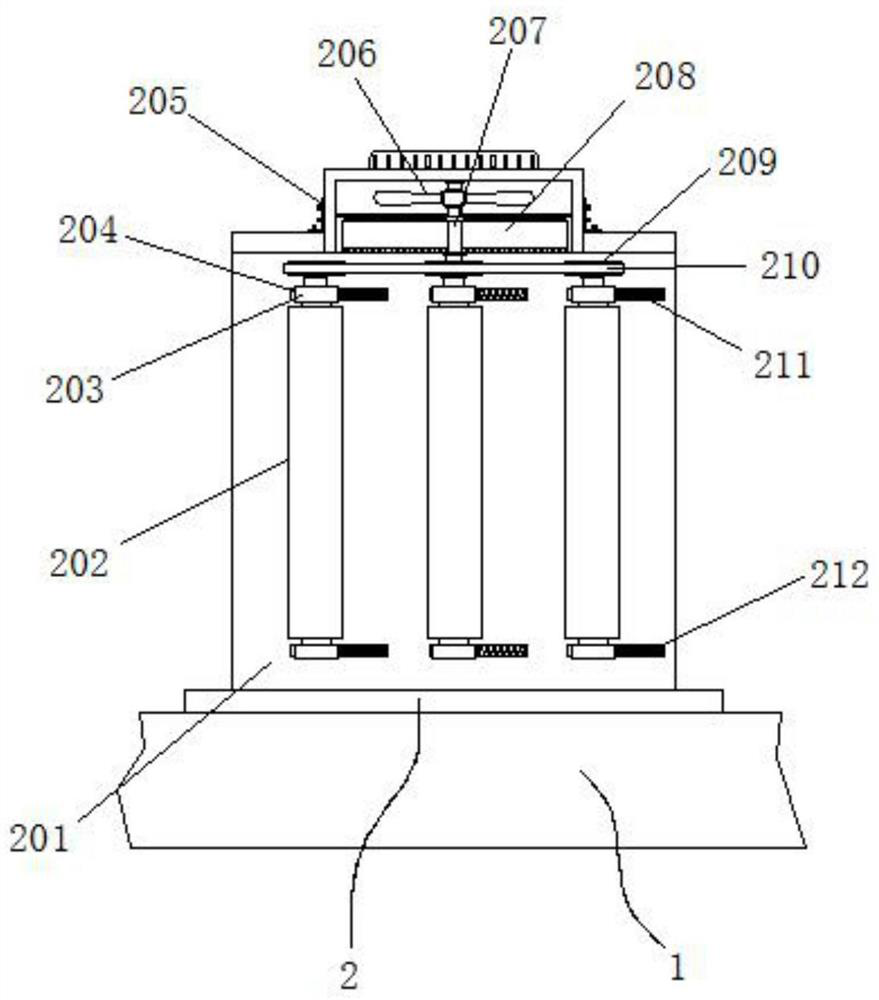

[0033] Embodiment 2: The cleaning mechanism 2 consists of a plate 201, a brush cylinder 202, a fixed block 203, a slider 204, a casing 205, a negative pressure fan 206, a transmission rod 207, a collection frame 208, a linkage belt 209, a runner 210, a sliding The groove 211 and the return spring 212 are formed. The plate 201 is fixedly connected to both sides of one side of the top of the base 1, respectively. Three sets of chute 211 are respectively set at the top and bottom of one end of the plate 201, and the inner side of the chute 211 is fixedly connected with a reset A spring 212, one side of the return spring 212 is fixedly connected with a slider 204, and one end of the slider 204 is fixedly connected with a fixed block 203, and a brush cylinder 202 is movably connected between the top and bottom ends of the inner side of the fixed block 203, and the brush cylinder A runner 210 is fixedly connected to the top of the plate 202 through the fixed block 203, a linkage belt...

Embodiment 3

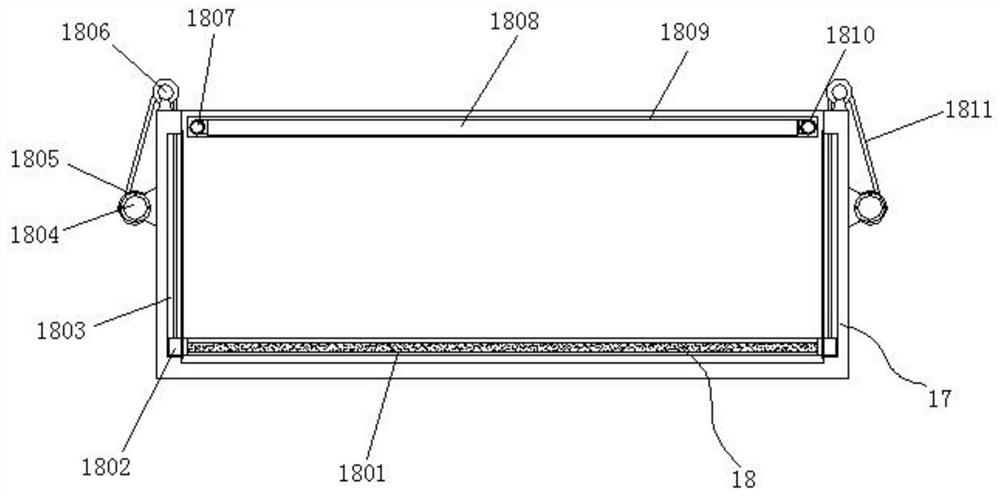

[0037] Embodiment 3: The slag scraping mechanism 18 is composed of a filter disc 1801, a connecting block 1802, an active chamber 1803, a first motor 1804, a winding disc 1805, a guide wheel 1806, a transverse screw 1807, a cleaning roller 1808, a through groove 1809, a sleeve The cylinder 1810, the rope 1811, the second motor 1812 and the waste box 1813 are composed. The movable chambers 1803 are respectively arranged at both ends of the inside of the paint pool 17. The inner of the movable chamber 1803 is provided with a connecting block 1802, and the A filter disc 1801 is fixedly connected between one side, the winding disc 1805 is movably connected to both sides of the outer side of the paint pool 17, and one end of the winding disc 1805 is fixedly connected with a first motor 1804, and the model of the first motor 1804 can be YVF-801-4P, the guide wheels 1806 are movably connected to both sides of the top of the paint pool 17, one side of the take-up disc 1805 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com