Nylon slice process wastewater treatment device and its treatment method

A wastewater treatment and process technology, which is applied in the field of nylon slicing process wastewater treatment devices, can solve the problems of exhaust gas being discharged into the atmosphere and the effect of reducing ammonia nitrogen is not obvious, and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

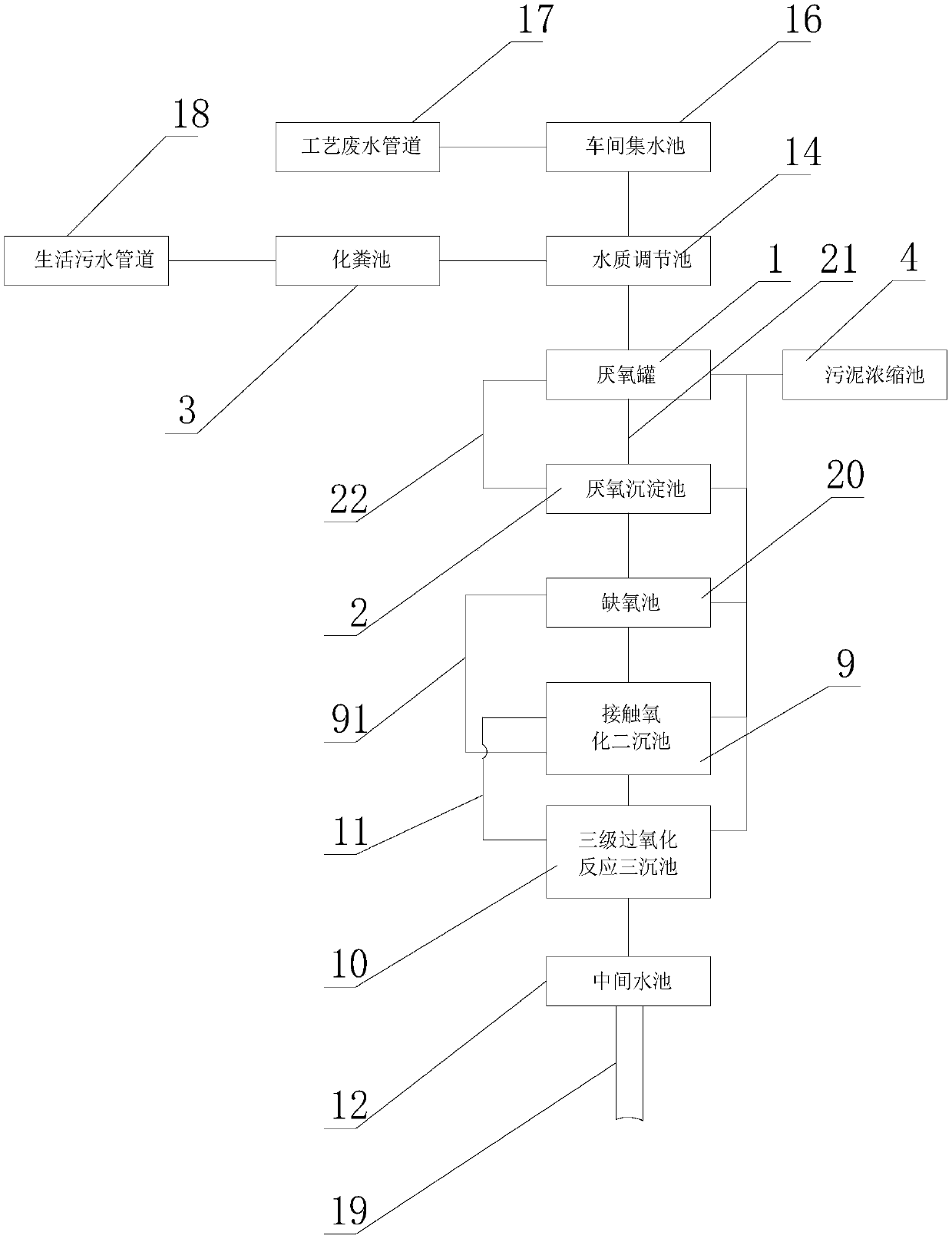

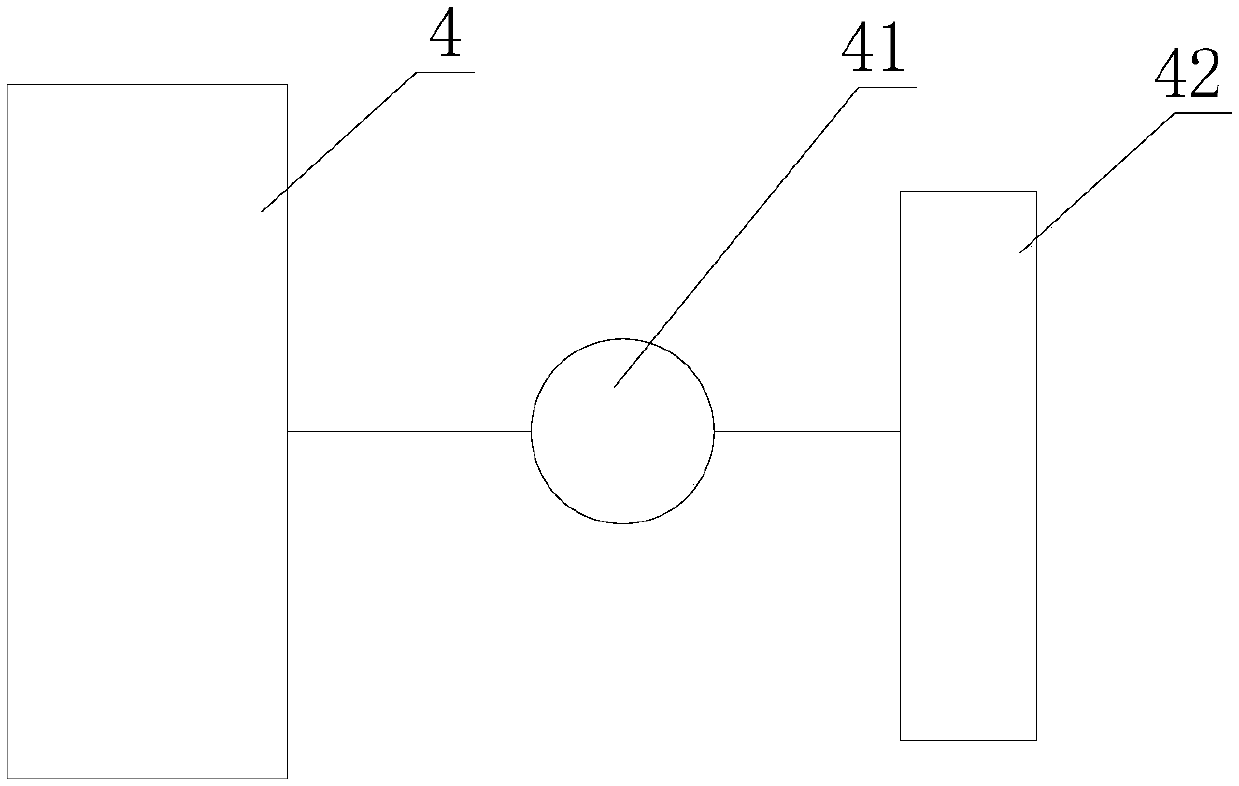

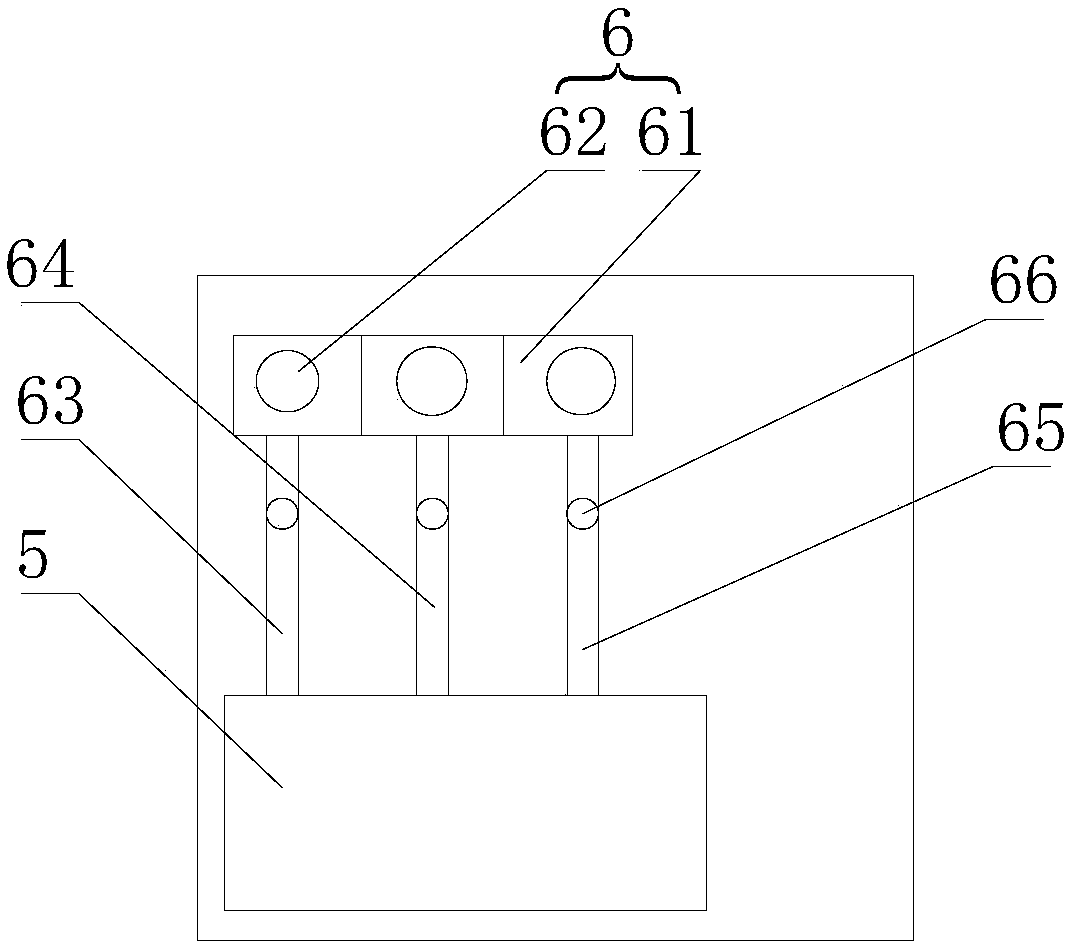

[0026] Such as figure 1 , figure 2 , image 3 As shown, the nylon slicing process wastewater treatment device includes an anaerobic tank 1, an overflow pipe 21 is arranged on the anaerobic tank 1, and an anaerobic sedimentation tank 2 and an anoxic tank are sequentially arranged on the overflow pipe 21 along the overflow direction. 20. Contact oxidation secondary settling tank 9, tertiary peroxidation reaction tertiary settling tank 10, anoxic tank 20 is connected with a sealed pipe connected with the oil furnace fan, anaerobic settling tank 2 is provided with a convenient anaerobic settling tank 2. The first return pipe 22 for sludge return, the first return pipe 22 is connected to the anaerobic tank 1, and the contact oxidation secondary settling tank 9 is provided with a second return flow that facilitates the return of the mixed solution in the contact oxidation secondary settling tank 9 The pipe 91 and the second return pipe 91 are connected to the anoxic tank 20, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com