Design method of layered double-metal hydroxide steel bar corrosion inhibitor based on density functional theory

A technology of density functional theory and layered bimetal, which is applied in chemical instruments and methods, aluminum compounds, design optimization/simulation, etc., can solve problems such as waste of experimental resources, experimental failure, blind goals, etc., to save experimental costs, Effects of shortening the research cycle and rationally designing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An example of a method for designing a layered double metal hydroxide steel bar rust inhibitor based on density functional theory according to the present invention, comprising the following steps:

[0030] (1) Mg 4 Al 2 (OH) 12 CO 3 ·3H 2 The O primitive cell model is imported into Materials Studio software, and a 3×3×1 supercell is constructed through the Supercell button; 3 2- Delete, replace some Mg atoms with Al atoms, so that Mg / Al=2; use the CASTEP module, the parameters are: GGA-PBE functional, supersoft pseudopotential, cut-off energy is 340eV, k point value is 3 × 3 × 1 ; Optimize NO in a 10×10×10 cubic crystal lattice 3 - The structure of the optimized NO 3 - uniformly placed between the supercell layers. and use the same steps to build Mg 2 Al-Cl LDHs model; calculation of Mg 2 Al-NO 3 LDHs, Mg 2 Binding energies of Al-Cl LDHs.

[0031] (2) The Fe original cell model was imported into Materials Studio software to optimize the structure of the...

Embodiment 2

[0038] Another example of a method for designing a layered double metal hydroxide steel bar rust inhibitor based on density functional theory according to the present invention, comprises the following steps:

[0039] (1) Mg 4 Al 2 (OH) 12 CO 3 ·3H 2 The O primitive cell model is imported into Materials Studio software, and a 3×3×1 supercell is constructed through the Supercell button; 3 2- Delete, replace some Mg atoms with Al atoms, so that Mg / Al=2; use the CASTEP module, set the parameters: GGA-PBE functional, supersoft pseudopotential, cut-off energy of 340eV, k point value of 3 × 3 × 1 ; Optimize NO in a 10×10×10 cubic crystal lattice 2 - The structure of the optimized NO 2 - uniformly placed between the supercell layers. and use the same steps to build Mg 2 Al-Cl LDHs model; calculation of Mg 2 Al-NO 2 LDHs, Mg 2 Binding energies of Al-ClLDHs.

[0040] (2) Import the Fe original cell model into the Materials Studio software to optimize the structure of th...

Embodiment

[0046] The results of the example are as follows:

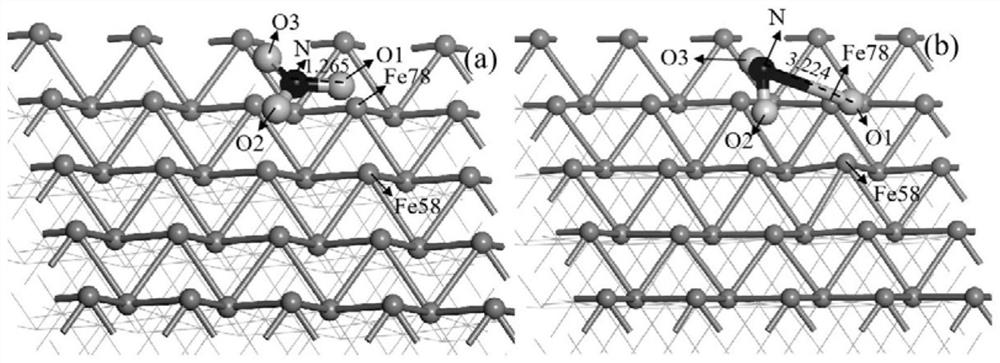

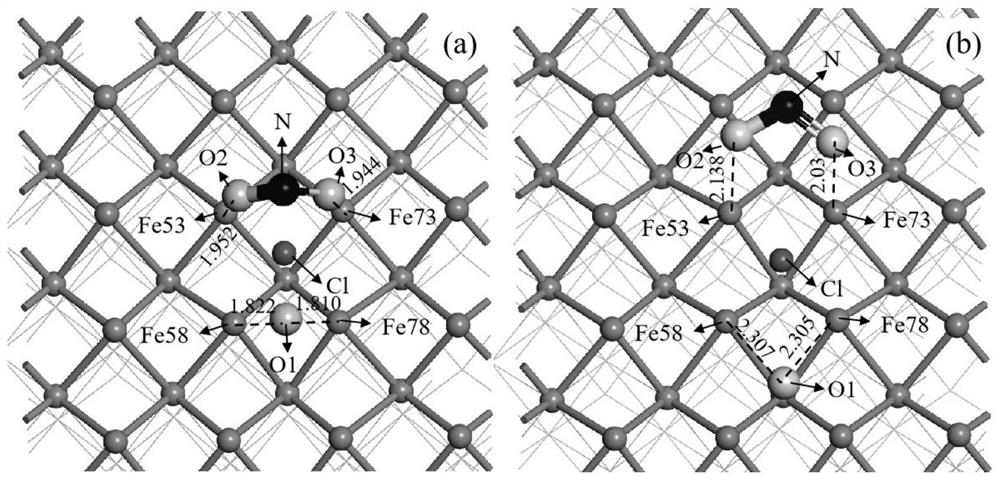

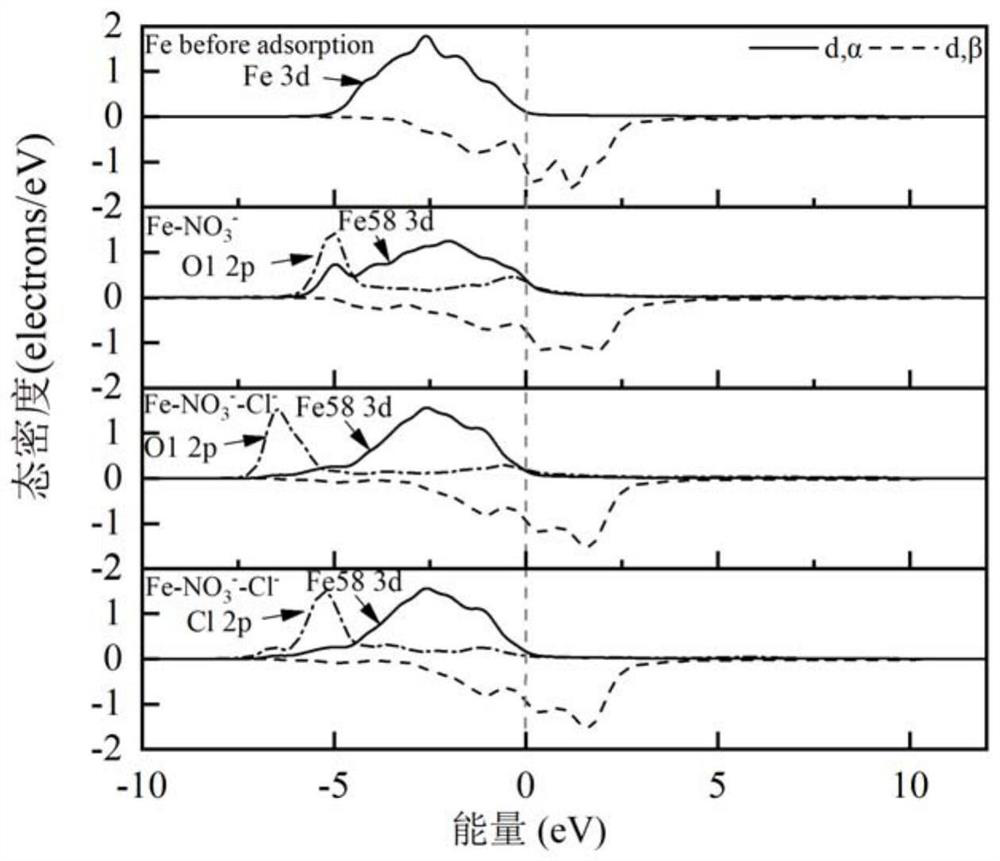

[0047] Table 1 is the Mg in Examples 1 and 2 2 Al-NO 3 LDHs, Mg 2 Al-NO 2 LDHs, Mg 2 Lattice constants and binding energies of Al-Cl LDHs, where Mg 2 Al-NO 3 The binding energy of LDHs is -45.534 eV, Mg 2 The binding energy of Al-Cl LDHs is -49.965 eV; the ion exchange sequence Cl - >NO 3 - , so Mg 2 Al-NO 3 LDHs have efficient chloride ion capture ability. figure 1 is Mg in Example 1 2 Al-NO 3 NO of LDHs 3 - The configuration before and after adsorption on Fe(100), the N-O1 is broken after adsorption, and the bond length is given by become And O1 moves between Fe58 and Fe78; the Mulliken charge before and after adsorption in Table 2 shows that Fe58 and Fe78 transfer 0.52e outward, of which 0.36e is transferred due to the adsorption of O1, and the other part is transferred to N; indicating that N-O1 Bond breakage is due to NO 3 - Redox with Fe(100). figure 2 Adsorption of NO on Fe(100) Surface 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com