Tail gas exhaust system, exhaust method and semiconductor equipment

A technology of exhaust and suction system and exhaust gas, which is used in semiconductor/solid-state device manufacturing, electrical components, program-controlled manipulators, etc., can solve problems such as low production efficiency, and achieve the effect of simple structure, good exhaust gas removal effect, and prevention of by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

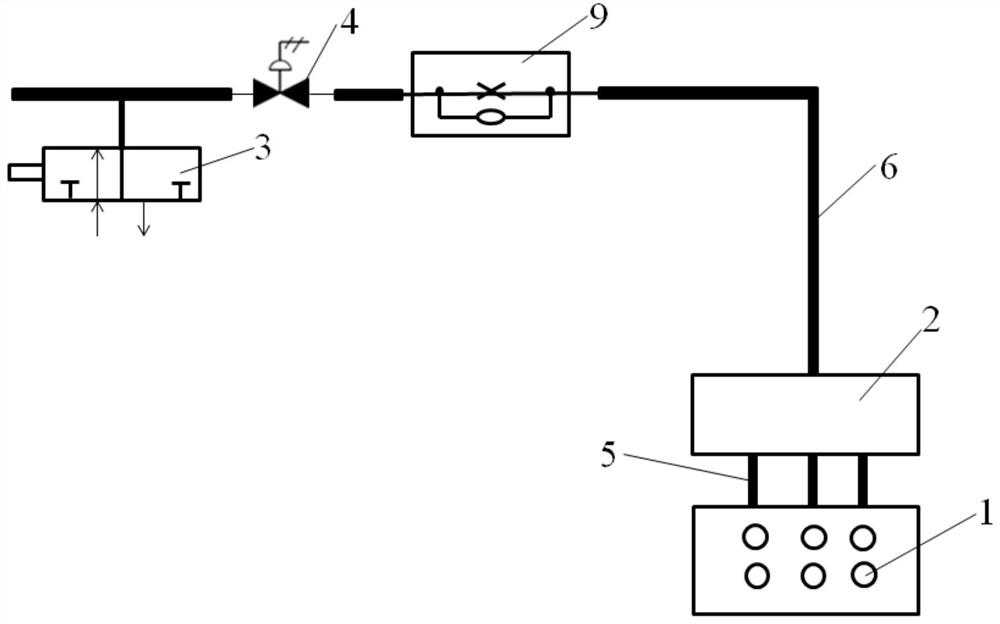

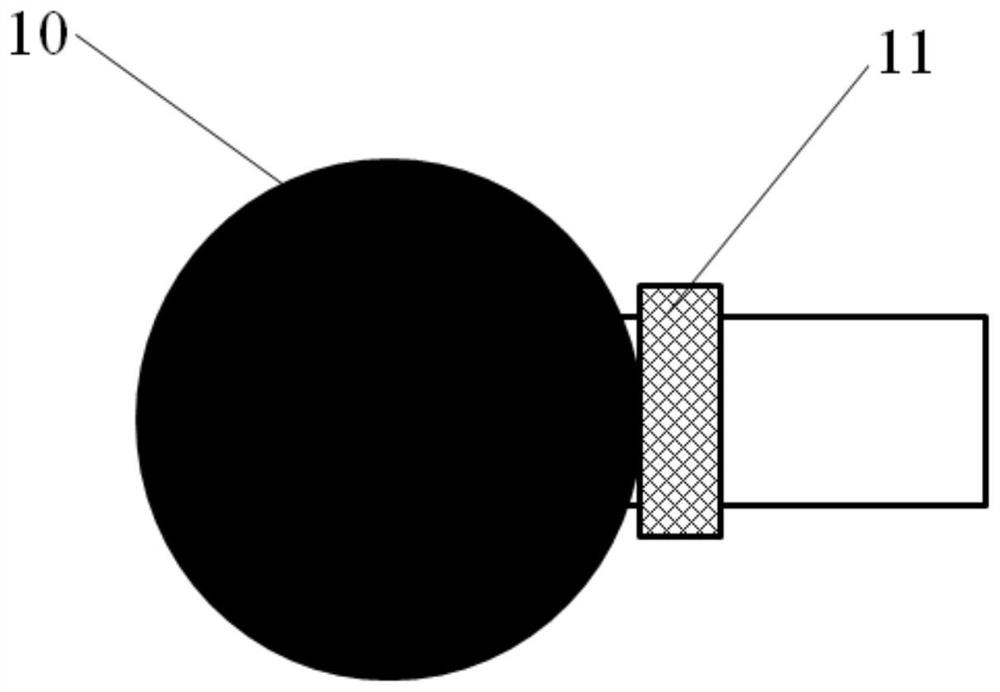

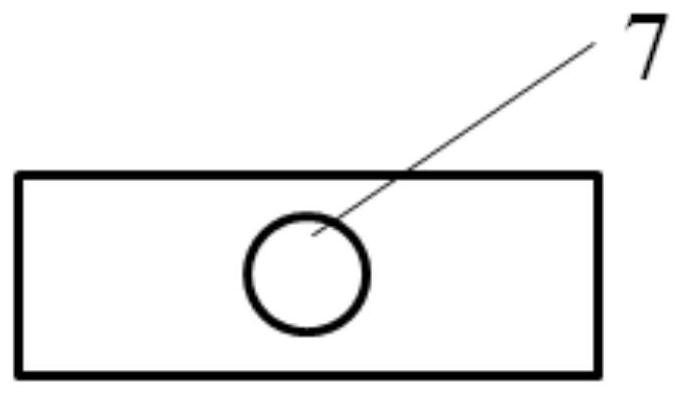

[0047] A specific embodiment of the present invention discloses a tail gas removal system, which is used to discharge the tail gas used in the process and remaining on the surface of the wafer. like figure 1 As shown in the figure, the exhaust gas removal system includes a plurality of micropores 1 arranged on the surface of the end effector arm and an exhaust gas suction system communicated with the micropores on the surface of the end effector arm. -Split), solenoid valve 3, pneumatic valve 4, discharge line and air extraction device (not shown in the figure).

[0048] It should be noted that, since the purpose of arranging the micro-holes is to remove the residual gas adsorbed on the surface of the wafer, the arrangement position of the micro-holes needs to be close to the wafer. Therefore, the preferred embodiment is to place the micro-holes on the surface of the end effector arm.

[0049] In a possible implementation manner, the region with micro-holes on the end effect...

Embodiment 2

[0062] Yet another embodiment of the present invention discloses a method for removing exhaust gas using the exhaust gas removal system of the first embodiment. The exhaust gas removal process will be described in detail below.

[0063] First, in the standby state of the equipment, turn on the exhaust gas removal system to exhaust for a certain period of time, the exhaust gas is sucked through a plurality of micropores on the surface of the end effector arm, mixed in the inner cavity of the multi-branch mixing chamber, and then passed through the second The exhaust line enters the atmosphere transfer module. The exhaust gas removal time depends on the situation, generally a few seconds to tens of minutes.

[0064] As for the timing of turning on the exhaust gas removal system, it can also be turned on when a wafer is placed on the end effector arm. Alternatively, turn on the exhaust gas removal system when the semiconductor manufacturing equipment is idle.

[0065] Next, th...

Embodiment 3

[0069] Another embodiment of the present invention discloses a semiconductor device including the exhaust gas removal system of the first embodiment.

[0070] Compared with the prior art, the present invention can achieve at least one of the following beneficial effects:

[0071] (1) The present invention does not solve the problem that the by-products are scattered on the wafer and cause defects in the wafer by replacing the end-effector arm after the by-product is generated, but through structural improvement (that is, setting micro-holes on the surface of the end-effector arm) ) Exhaust exhaust gas to prevent the generation of by-products, and fundamentally solve the problem of wafer defects caused by by-products scattered on the wafer.

[0072] (2) The tail gas removal system of the present invention has a simple structure and good effect of tail gas removal, and the product yield is improved after using the tail gas removal system.

[0073] (3) By controlling the diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com