Method for producing propylene oligomer

A manufacturing method, a technology of propylene tetramer, applied in the direction of organic chemistry methods, chemical instruments and methods, hydrocarbons, etc., can solve the problems of short catalyst life, weak mechanical strength of solid phosphoric acid catalyst, etc., and achieve the effect of prolonging catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

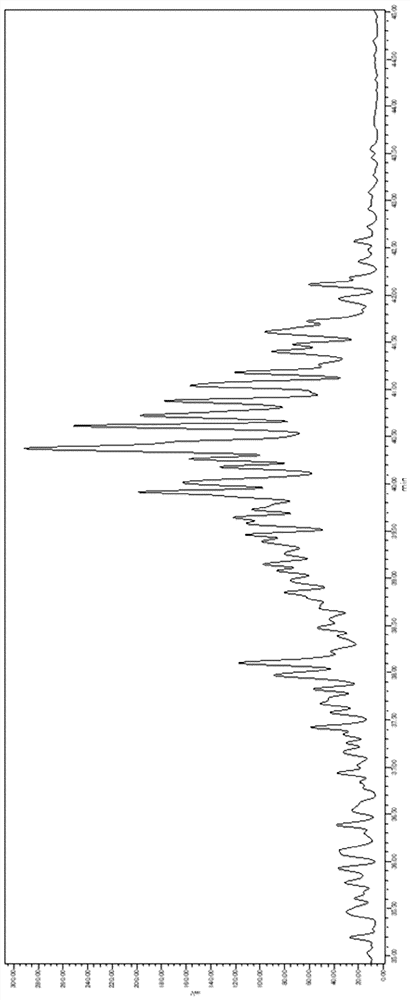

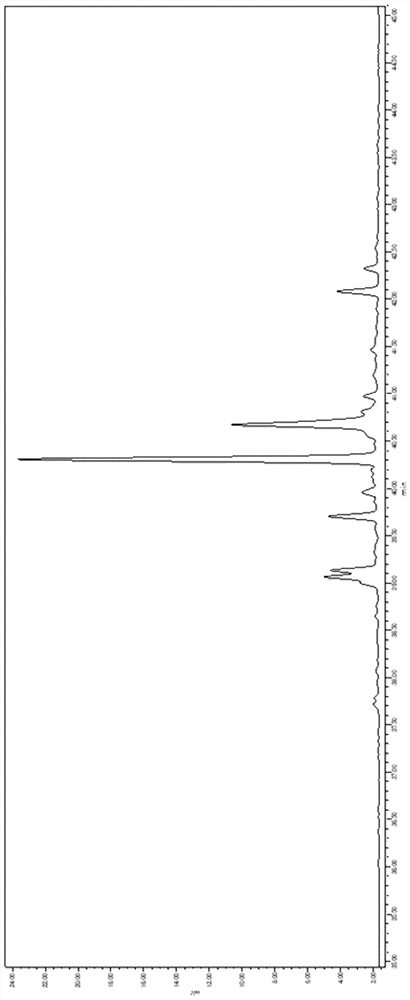

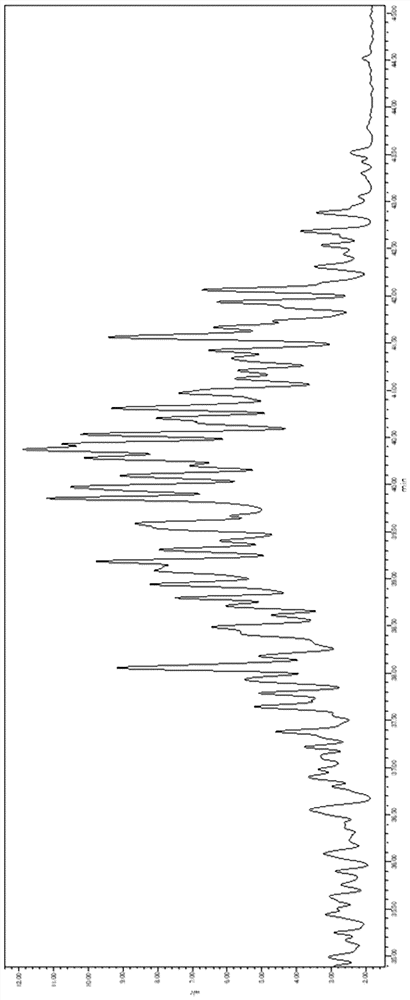

Image

Examples

no. 1 approach

[0036] The first embodiment of the present application is a technique related to a method for producing a propylene oligomer, which includes a step of: in the presence of at least one selected from the group consisting of a crystalline molecular sieve-containing catalyst and a phosphoric acid-containing catalyst, under a An oligomerization step of oligomerizing propylene at a temperature of 160° C.; a fractional distillation step of obtaining a fraction containing propylene trimers, propylene tetramers, or mixtures thereof; and, in the presence of a catalyst containing phosphoric acid , an isomerization step of isomerizing propylene trimers, propylene tetramers, or their mixtures contained in the aforementioned fractions.

[0037] Hereinafter, the first embodiment will be described in detail.

[0038] [Production method of propylene oligomer]

[0039] The method for producing a propylene oligomer according to the first embodiment includes a step of subjecting propylene to a t...

no. 2 approach

[0146] A second embodiment of the present application is a technique related to a method for producing a propylene oligomer, comprising: in the presence of at least one selected from the group consisting of catalysts containing phosphoric acid, under the condition of less than the critical pressure of propylene A step of isomerizing an oligomer containing a propylene trimer, a propylene tetramer, or a mixture thereof.

[0147] By isomerizing oligomers mainly composed of propylene trimers, propylene tetramers, or their mixtures, the isomerization reaction can be carried out in small batches, and a low branching degree can be obtained with high selectivity. The oligomer of the target degree of polymerization. In addition, the oligomer containing propylene trimer, propylene tetramer, or a mixture thereof as a main component exists in the form of a liquid phase even under a reaction pressure lower than the critical pressure of propylene. Therefore, the production method of the pr...

no. 3 approach

[0200]The third embodiment of the present application is a propylene oligomer in which the concentration of 4,6,6-trimethyl-3-nonene in the propylene tetramer is 30 mass % or more. Further, a third embodiment of the present application is a technique related to a method for producing a propylene oligomer, wherein the method for producing the propylene oligomer comprises: subjecting propylene to a catalyst in the presence of a crystalline molecular sieve-containing catalyst. In the step of oligomerization, the BET specific surface area of the crystalline molecular sieve obtained by the nitrogen adsorption method is set to a [m 2 / g], and the micropore specific surface area of the aforementioned crystalline molecular sieve obtained by analyzing the adsorption isotherm measured by the nitrogen adsorption method by the t-plot method is set as b [m 2 / g], a / b is 1.8 or less.

[0201] In addition, the "micropore" in this invention means the pore whose diameter is 2 nm or less a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com