Automatic mould closing system and mould closing method for cabin casting mould

A casting mold and cabin technology, which is applied in the direction of casting mold handling equipment, casting equipment, metal processing equipment, etc., can solve the problems of low box closing efficiency and poor quality consistency of box closing, so as to maintain stability and realize automatic production. , the effect of reducing labor intensity

Inactive Publication Date: 2022-05-31

新江科技(江苏)有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Aiming at the problems existing in the prior art, the object of the present invention is to provide an automatic box closing system and box closing method for cabin casting molds. This solution effectively solves the problem of the low efficiency of traditional manual box closing through the combination of mechanized equipment and systems. , The problem of poor consistency of box-closing quality reduces the number of operators in the box-closing process and reduces the labor intensity of workers. At the same time, the box-closing system organically combines the molding link with the pouring link, which improves the transfer efficiency between different processes and realizes Automated production of cabin products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

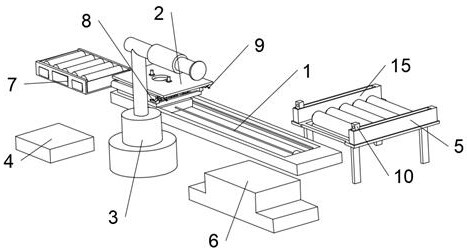

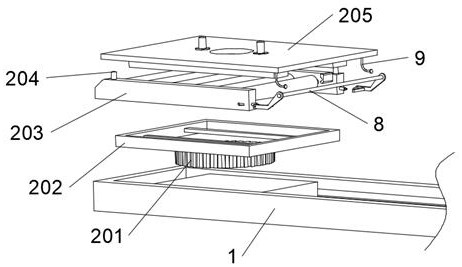

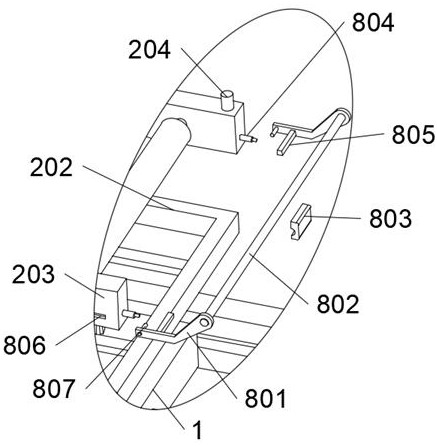

The invention discloses an automatic mold closing system and method for cabin casting molds, and belongs to the technical field of casting mold closing. The automatic mold closing system for cabin casting molds comprises a lead screw conveying base table, a mold closing working sliding table is fixedly connected to the lead screw conveying base table, and a casting mold grabbing robot is arranged behind the left side of the lead screw conveying base table; a casting mold transfer pouring roller way is arranged in front of the right side of the lead screw conveying base table, a manual operation table is arranged in front of the left side of the lead screw conveying base table, and the problems that traditional manual mold closing efficiency is low and mold closing quality consistency is poor are effectively solved through combined use of systems of mechanical equipment; compared with the prior art, the mold closing system has the advantages that the number of operators in the mold closing procedure is reduced, the labor intensity of workers is reduced, meanwhile, the molding link and the pouring link are organically combined, the transfer efficiency among different procedures is improved, and automatic production of cabin products is achieved.

Description

A cabin casting automatic box closing system and box closing method technical field The present invention relates to the technical field of casting box closing, more specifically, to a kind of cabin casting mold automatic box closing system and Closing method. Background technique Sand casting refers to a casting method for producing castings in sand molds. Steel, iron and most non-ferrous alloy castings can be Obtained by sand casting method. Because the molding materials used in sand casting are cheap and easy to obtain, the casting mold is easy to manufacture, and the single casting cost is low. Part production, batch production and mass production can all be adapted, and it has been the basic process in casting production for a long time. [0003] After the sand mold is dried, the process that the sand mold and the sand core are combined to form a mold according to the requirements of the casting process drawing is a closed box. combine The box is an important ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D33/04B22D33/02

CPCB22D33/04B22D33/02

Inventor 古金涛张旭亮邹文兵陈斌李宝辉昝林潘龙刘壮家崔恩强余国康

Owner 新江科技(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com