Integral forming method of LCM (Liquid Crystal Module) with complex structure workpiece and workpiece

A technology of overall forming and complex structure, applied in the field of LCM, can solve complex problems, achieve long production cycle, improve slow fiber infiltration speed, and ensure dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

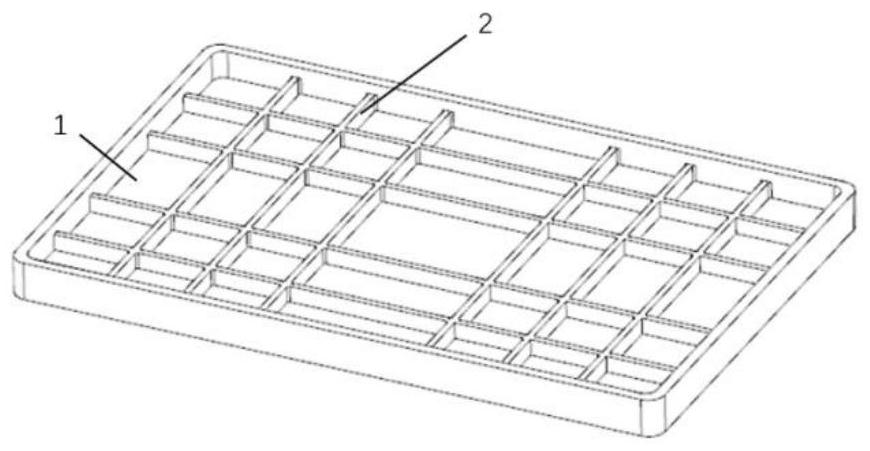

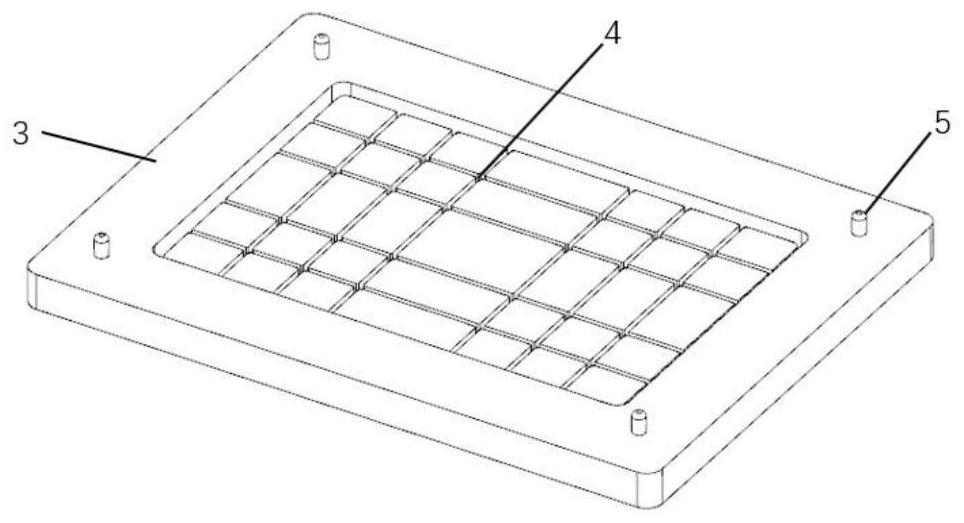

[0046] In this embodiment, the mold structure see image 3 and Figure 4 , wherein the first lower film 3 includes grooves 4 and positioning columns 5; the first upper mold 6 includes injection ports 7, exhaust ports 8, sealing grooves 9 and positioning holes 10. Wherein groove 4 is the characteristic structure of this mould.

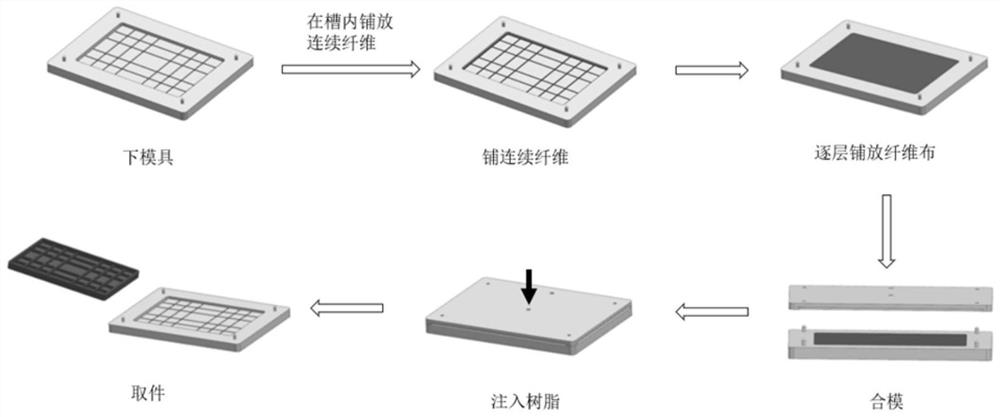

[0047] Such as figure 1 As shown, the specific process of using the resin transfer molding process to produce parts with ribs is as follows:

[0048] 1) Lay T964 continuous glass fiber in the groove in the lower mold, and then lay 16 pieces of cut EBX1200 (+45 / -45) EP biaxial glass fiber cloth (60cm×40cm) layer by layer in the mold cavity middle.

[0049] 2) Paste sealant in the sealing groove of the upper mold, and then close the mold.

[0050] 3) Take SWANCOR 2511-1A epoxy resin, 2511-1BS curing agent, 1800g in total, mix evenly at 30°C according to the ratio of 10:3, connect the injection port with the resin through a catheter, open the injectio...

Embodiment 2

[0054] In this embodiment, the mold structure is as Figure 7 As shown, the second lower membrane 13 includes a buckled cavity 14 and a positioning post 15 . The cavity 14 of the buckle is a characteristic structure of the mould.

[0055] Such as Figure 5 As shown, the specific process of using the vacuum-assisted resin transfer molding process to produce parts with buckles is as follows:

[0056] 1) Paste the sealant around the cavity of the lower mold, and do not tear off the white paper on the sealant at this time.

[0057] 2) Lay 6mm chopped carbon fiber in the cavity corresponding to the buckle position of the mold, so that the chopped carbon fiber fills the buckle cavity, and then lay 5 pieces of cut T300 woven carbon fiber cloth (10cm×6cm) layer by layer placed in the mold cavity.

[0058] 3) Cut the vacuum bag into a rectangle of 14cm×10cm, cut out a 5mm injection port and a 3mm exhaust port on the vacuum bag with scissors, tear off the white paper on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com