Heat pump type belt type low-temperature sludge drying machine

A technology of sludge drying and low temperature, which is applied in dehydration/drying/thickened sludge treatment, heat recovery system, energy-saving heating/cooling, etc. The problem of low working efficiency of the chemical machine is achieved, and the dew point temperature rises, the evaporation is promoted, and the dehumidification effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

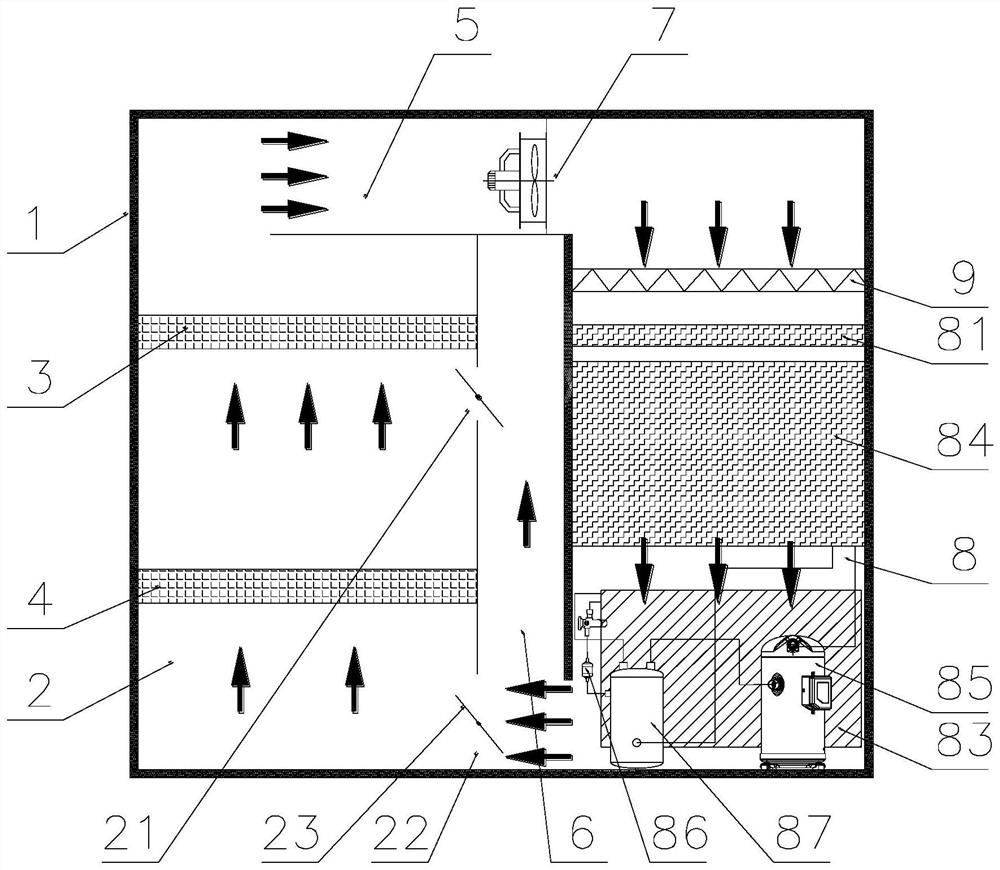

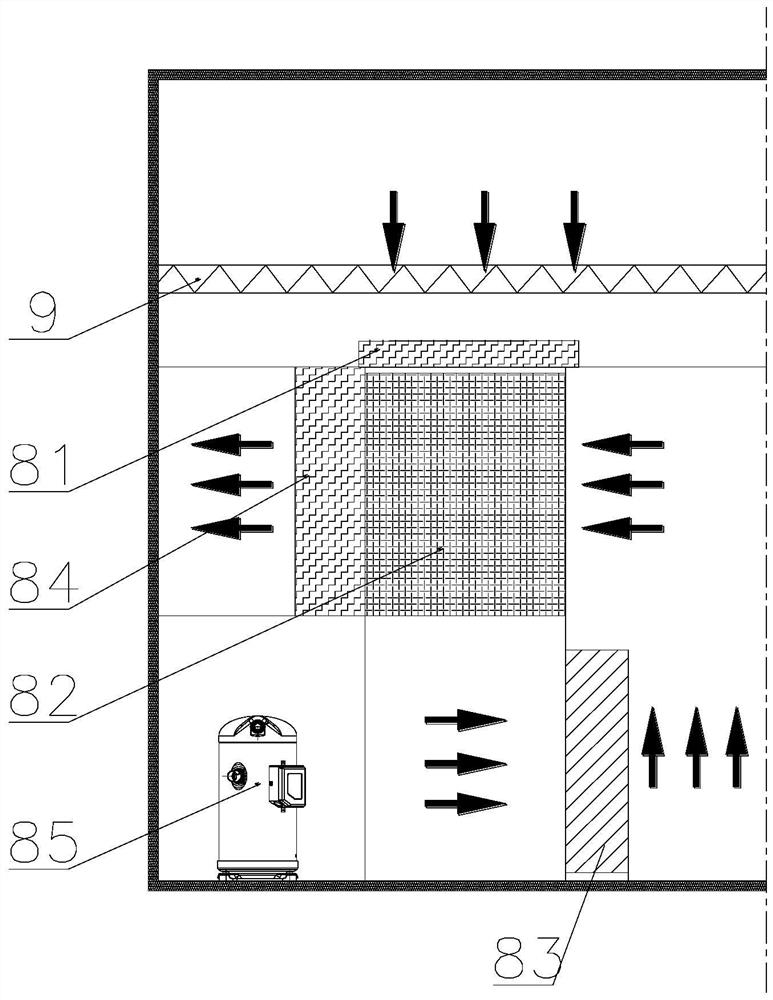

[0021] The present invention will now be described in detail with reference to the accompanying drawings. This figure is a simplified schematic diagram, and only illustrates the basic structure of the present invention in a schematic manner, so it only shows the structure related to the present invention.

[0022] like figure 1 , 2 As shown, a heat pump belt type low-temperature sludge dryer of the present invention includes a body 1, and the outer side of the body 1 is covered with a thermal insulation layer. The machine body 1 is provided with a drying room 2 and a heat pump system 8 for providing dry and hot air to the drying room 2. The drying room 2 is provided with a first conveyor belt 3 and a second conveyor belt 4. The first conveyor belt 3 is arranged above the second conveyor belt 4, the upper space of the body 1 is provided with a first air duct 5 for connecting the drying room 2 and the heat pump system 8, and the first air duct 5 is provided with a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com