Intelligent control system of biomass gasification power generation system

A technology of an intelligent control system and power generation system, which is applied in the manufacture of pyrolignoic acid, energy input, special forms of dry distillation, etc., to achieve the effect of remarkable intelligence, simple operation and high control precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

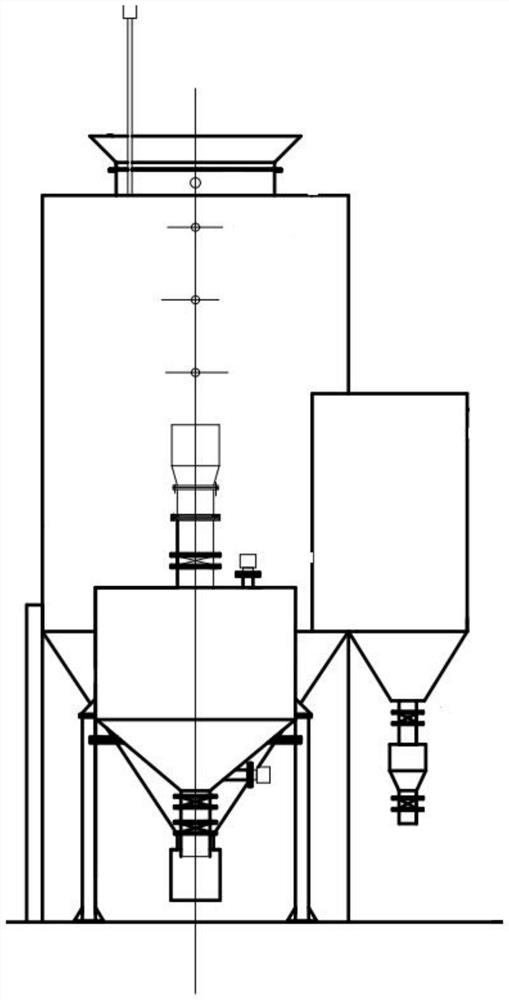

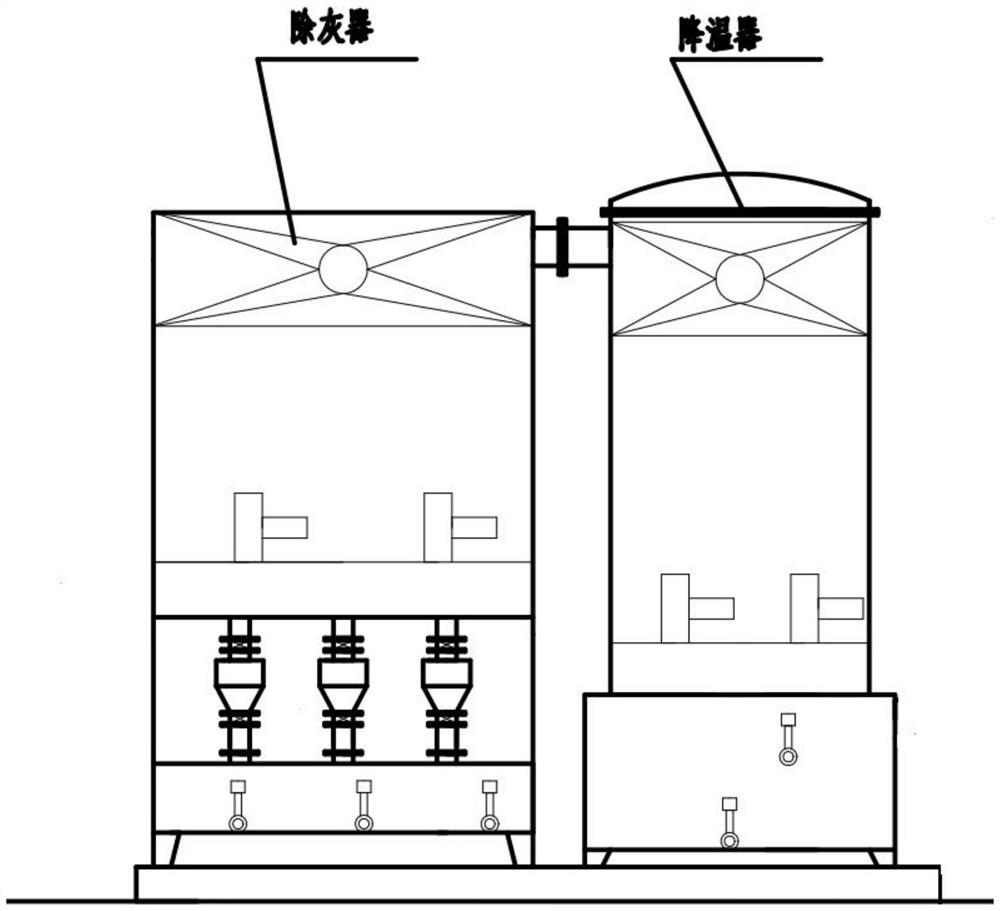

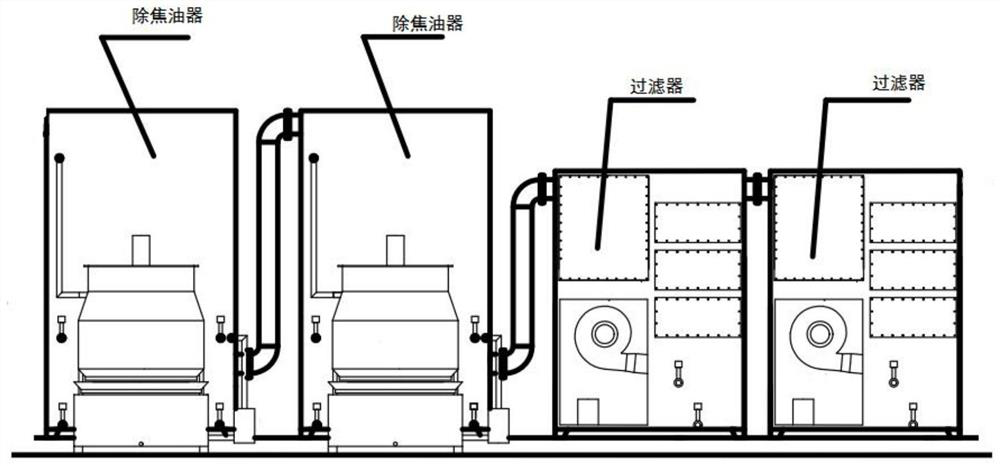

Image

Examples

Embodiment 1

[0035] This embodiment discloses an intelligent control system of a biomass gasification power generation system, and specifically discloses the specific implementation content of the system in the independent control mode of each subsystem.

[0036] specific:

[0037] In practical application, in addition to the biomass gasification power generation system, there is also a biomass raw material conveying system as the prior art to assist in the conveying of biomass raw materials, wherein the biomass raw material conveying system includes: belt conveyor, wood vinegar spray system, multiple biomass raw material storage bins, multiple level switch sensors;

[0038] When the biomass raw material conveying system works independently, multiple level switch sensors detect the biomass raw material level in multiple biomass raw material raw material storage bins, and send signals to the belt conveyor and wood vinegar spray according to the material level detection results. System; bel...

Embodiment 2

[0048] This embodiment discloses an intelligent control system of a biomass gasification power generation system, and specifically discloses the specific implementation content of the PLC control method adopted by the system on the basis of Embodiment 1.

[0049] specific:

[0050] In the PLC control mode, the biomass raw material conveying system controls the startup and shutdown sequence through the PLC control system. Start-up sequence: First, the PLC control system controls the belt conveyor to start, and then according to the preset time in the PLC control system, the variable frequency water pump is controlled to start. Shutdown sequence: PLC control system controls the variable frequency water pump to shut down first, and then shut down the belt conveyor. Through the PLC control system, the gasification control system controls the preparatory work and the sequence of startup and shutdown before starting the machine. Preparatory work: PLC control system controls each c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com