Method and equipment for low-carbon manufacturing of iron by using hydrogen and oxygen mixed gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

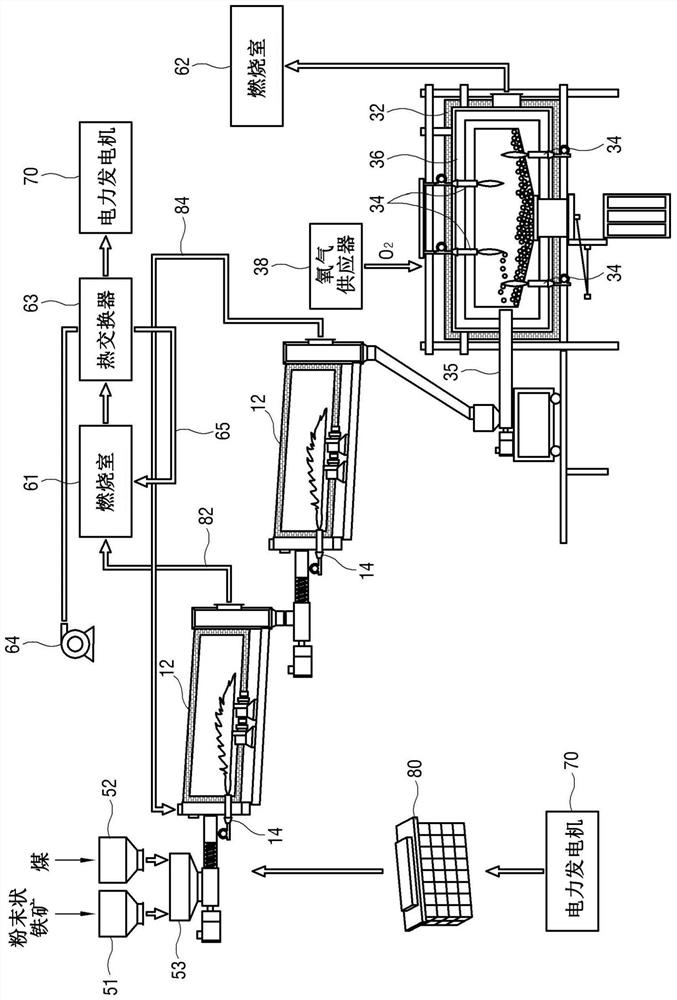

Image

Examples

Embodiment Construction

[0036] As a heat source with very few harmful substances, gas mixed with hydrogen and oxygen has attracted attention. The present application provides a method of using a hydrogen / oxygen gas mixture as a heat source to provide the temperature required for iron production.

[0037] The hydrogen / oxygen mixed gas is a gas in which gaseous hydrogen and gaseous oxygen are mixed, and is also called Brown's gas, water gas, or the like. Brown gas can be easily produced by electrolyzing water, so Brown gas can be directly produced and used at a construction site using an electrolysis device. Therefore, unlike hydrogen, no high-pressure storage tanks are required, which significantly reduces the burden and cost of storage or transportation. In addition, Brown gas can raise the temperature of the object to be heated from room temperature to over 1800°C within 2 to 3 seconds, therefore, compared with fossil fuels (LNG, LPG, diesel, etc.), a very high combustion temperature.

[0038] Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com