Columnar electromagnetic wave lens

An electromagnetic wave, cylindrical technology, applied in the lens, electrical components, antennas and other directions, can solve the problems of high cost, insufficient density, two-dimensional randomness, etc., and achieve the effect of easy mass production, high product consistency, and stable electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

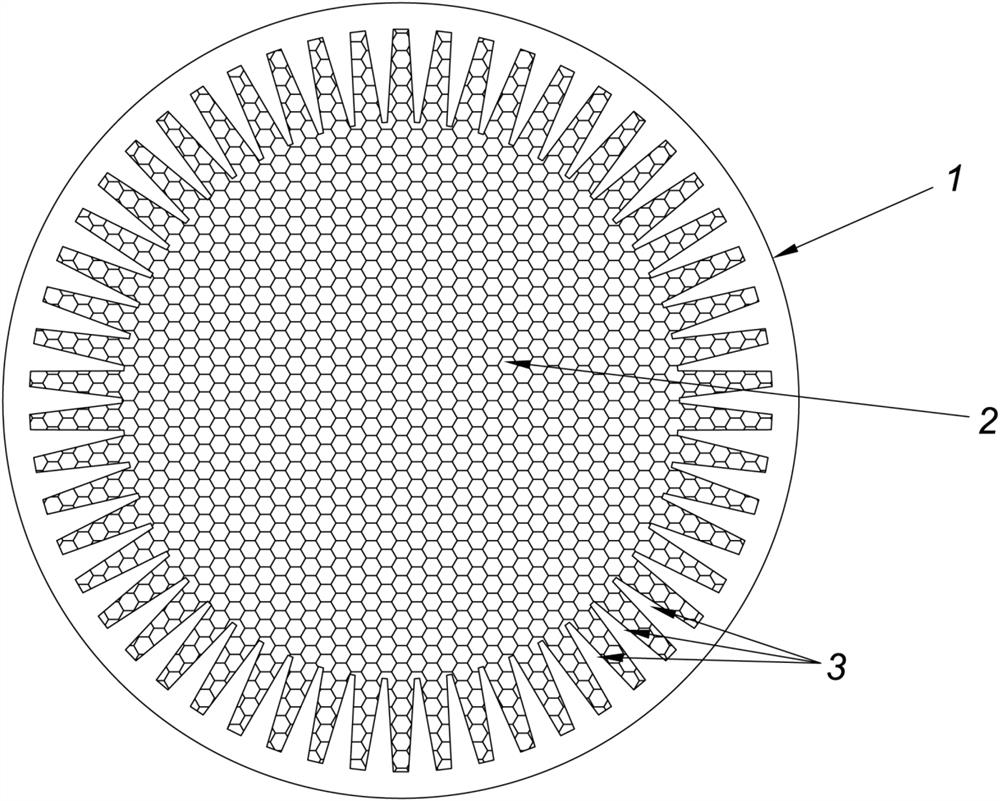

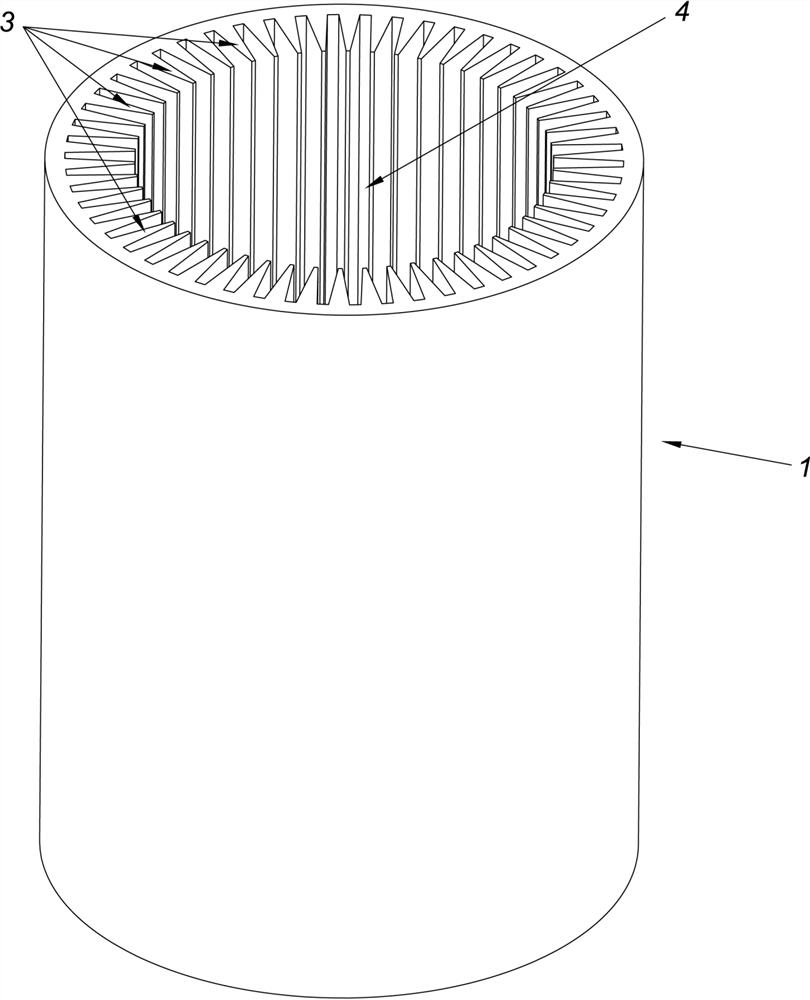

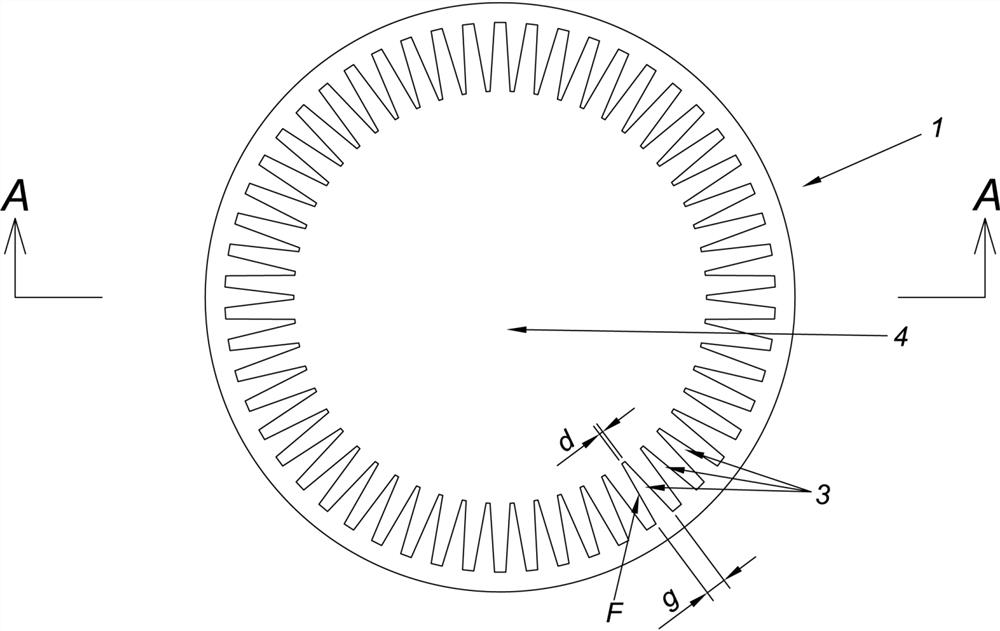

[0042] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the cylindrical electromagnetic wave lens of this embodiment includes: an outer body 1 , a medium particle 2 , an upper end cap and a lower end cap (the upper end cap and the lower end cap are not shown in the figure). Among them: as figure 2 , image 3 , Figure 4 As shown, the outer body 1 is a cylindrical structure, and there are 54 tooth-like structures 3 evenly distributed in the circumferential direction inside the outer body 1. The outer body 1 and its tooth-like structures 3 are made of foamed materials through the mold. Made of foam. The tops of the tooth-like structures 3 are all facing the central axis C of the outer body 1; the space inside the outer body 1 is called the medium cavity 4, and the medium particles 2 are filled in the medium cavity 4, and there is no space between the medium particles 2. adhesive. The dielectric constant values of the exobody 1 and the tooth-like structure 3 ...

Embodiment 2

[0046] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the medium particles are divided into first-type medium particles 21 and second-type medium particles 22 . The dielectric constant value of the first type of dielectric particles 21 is 1.8, the dielectric constant value of the second type of dielectric particles 22 is 2.1, and the layer formed by the first type of dielectric particles 21 is larger than that of the second type of dielectric particles 22 The layer is further away from the central axis of the exosome.

[0047] The physical structures of the first medium particles 21 and the second medium particles 22 are almost the same, and metal wire segments are embedded between the two layers of foamed materials, the difference lies in the number and / or length of the embedded metal wire segments. , so that they have different dielectric constant values.

Embodiment 3

[0049] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the number of tooth-like structures 3 of the outer body 1 is larger, and the roots of the tooth-like structures 3 are not connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com