Hydraulic motor pump with forced flow heat dissipation function

A technology of hydraulic motor and forced flow, which is applied to components of pumping devices for elastic fluids, machines/engines, liquid variable displacement machinery, etc., which can solve problems such as poor performance, and achieve performance improvement, temperature reduction, and reduction effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

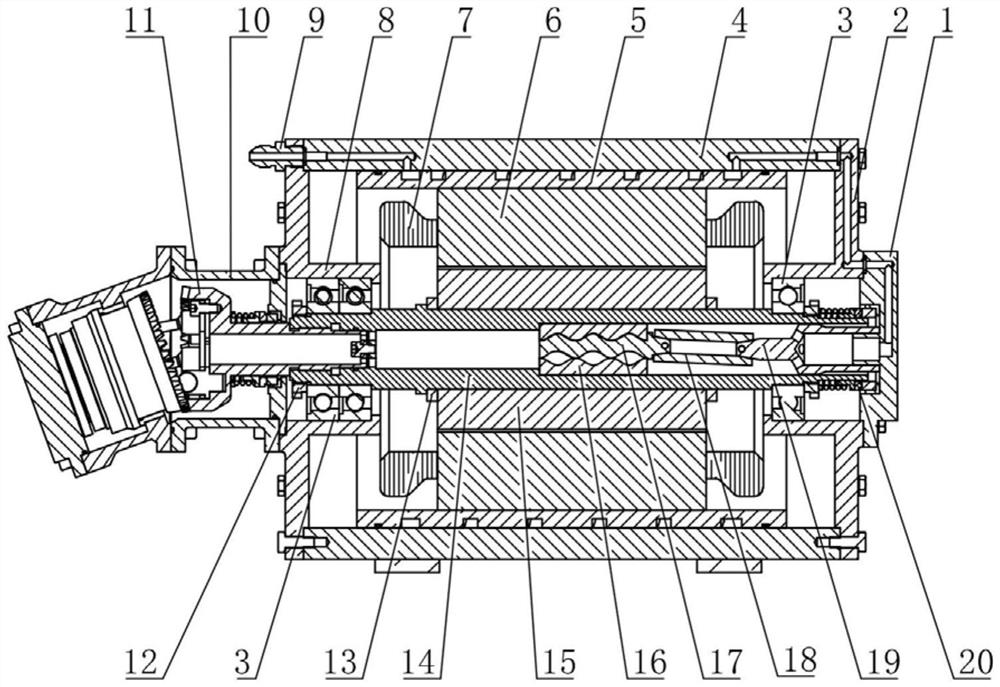

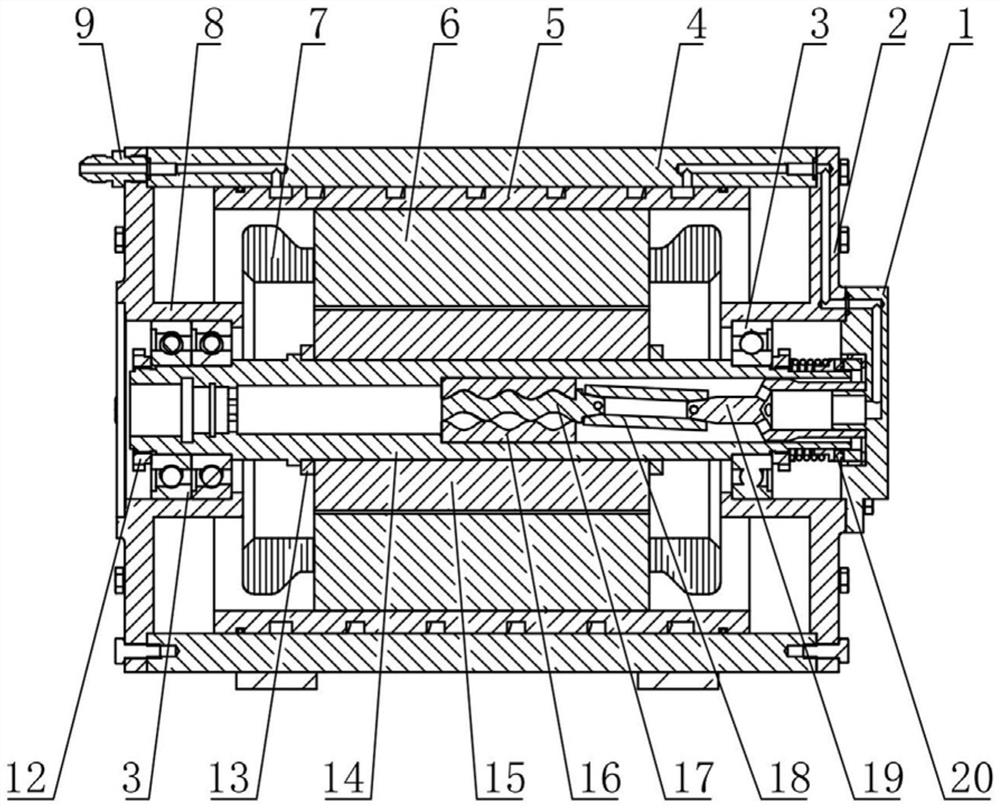

[0041] like figure 1 As shown, the hydraulic motor pump with forced flow heat dissipation function of the present invention includes a motor, a hydraulic pump and a transmission shaft 11, wherein the motor includes a motor casing, a stator 6, a rotor 15 and a rotating shaft 14, the stator 6 is provided with a coil 7, the rotor 15 is sleeved on the rotating shaft 14 and fixed by the rotor positioning ring 13, and the rotating shaft 14 is driven by the rotor 15 to rotate. In this embodiment, the hydraulic pump is an oblique axis pump, and the specific structure is the same as that of the oblique axis pump in the Chinese invention patent application with the application publication number CN114001007A. Since the specific structure of the oblique axis pump is not the protection point of the present invention, in the This will not be described in detail.

[0042] like figure 1 As shown, the left end of the motor casing is provided with a left end cover 8, and the right end is pro...

Embodiment 1

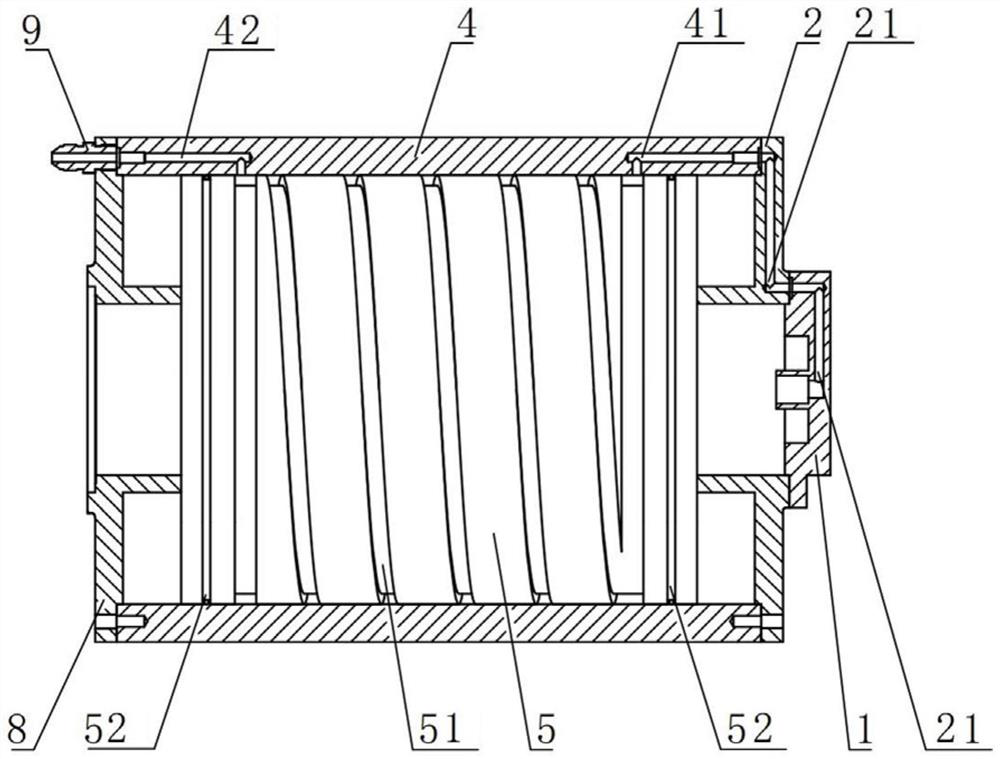

[0050] In Embodiment 1, the inner wall of the fixing sleeve is provided with a spiral groove, and a spiral rod serving as a central rod is inserted into the fixing sleeve. The outer peripheral surface of the spiral rod and the spiral groove together constitute a spiral pumping structure. In this embodiment, different from Embodiment 1, the inner wall of the fixing sleeve is provided with a spiral groove, the central rod is not inserted into the fixing sleeve, and the spiral pumping structure is formed only by the spiral groove.

specific Embodiment 3

[0052] The central rod in Example 1 is a screw rod. In this embodiment, the difference from Embodiment 1 is that the outer peripheral surface of the central rod is a rod with helical blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com