Preparation of acetylacetonato carbonyl rhodium and method for synthesizing butyraldehyde from propylene carbonyl

A technology of acetone carbonyl rhodium and acetylacetone, which is applied in the field of precious metal catalyst synthesis, can solve the problems of high product chlorine content, long preparation process, complicated post-treatment, etc., and achieves low chloride ion content, high product purity, and improved product yield. and the effect of purity

Pending Publication Date: 2022-06-03

JINCHUAN GROUP LIMITED +1

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The object of the present invention is to provide a kind of one-step synthesis high-yield, the preparation method of rhodium carbonyl acetylacetonate with low chlorine content for the technical problem that above-mentioned rhodium carbonyl acetylacetonate preparation process flow is long, aftertreatment is complicated, product chlorine content is high, Simultaneously also provide a kind of method that utilizes the rhodium acetylacetonate carbonyl prepared by this method to catalyze the carbonylation of propylene to butyraldehyde

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

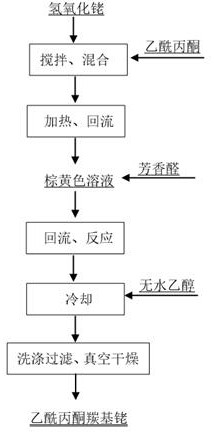

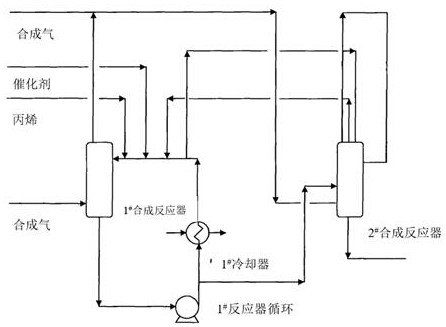

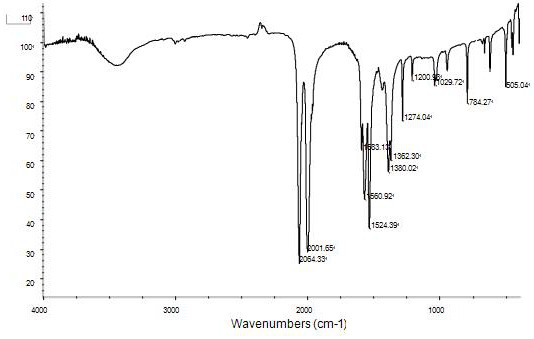

The method comprises the following steps: stirring and mixing rhodium hydroxide and acetylacetone, heating to a reflux temperature, reacting, adding aromatic aldehyde after the system becomes brown yellow from light yellow, and continuously reacting at the reflux temperature, so as to obtain the acetylacetone carbonyl rhodium. After the reaction is finished, adding absolute ethyl alcohol, filtering, washing a filter cake with absolute ethyl alcohol, and carrying out vacuum drying on the filter cake to obtain carbonyl rhodium acetylacetonate; the acetylacetonatocarbonyl rhodium prepared by the method and triphenylphosphine are dissolved in liquid-phase propane, carbon monoxide and hydrogen are introduced into a hydroxyl synthesis kettle for hydroxyl synthesis reaction, and finally butyraldehyde is prepared. The preparation method provided by the invention can be used for preparing acetylacetone carbonyl rhodium without chlorine impurities causing poisoning of the catalyst, and acetylacetone is both a reactant and a solvent in the reaction, so that no side reaction occurs, and the obtained acetylacetone carbonyl rhodium product is high in purity and can be directly applied to a reaction for synthesizing butyraldehyde through carbonyl of propylene without a recrystallization process.

Description

technical field [0001] The invention relates to the field of precious metal catalyst synthesis, in particular to the preparation of rhodium acetylacetone carbonyl and a method for synthesizing butyraldehyde by propylene carbonyl. Background technique [0002] Acetylacetone carbonyl rhodium is a ligand-coordinated chelated rhodium organic compound, which can be directly used to catalyze the hydroformylation of olefins when the corresponding ligand is used. Hydroformylation, also known as oxo, is an industrial method for preparing aldehydes by reacting olefins with hydrogen and carbon monoxide under high pressure (10-100 atm) heating (40-200 °C) and metal catalysis. Rhodium acetylacetonate carbonyl is usually prepared from water and rhodium trichloride. According to the preparation method of a kind of acetylacetonate dicarbonyl rhodium disclosed in CN102030781A, hydrated rhodium trichloride is dissolved in methanol or ethanol solution, the temperature is raised to 80 ° C and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07F15/00B01J31/22C07C47/02C07C45/50

CPCC07F15/0073B01J31/2213C07C45/505B01J2531/822B01J2231/321C07C47/02Y02P20/584

Inventor 张静刘国旗白延利胡家彦任志勇李欢王红梅孟俊杰郅欢欢高嵩张宗磊王一帆朱婷高志磊

Owner JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com