Clean high-pressure cavitation energy extraction technology

A technology of clean energy and technology, applied in the direction of liquid variable displacement machinery, machine/engine, pump device, etc., can solve the problem that energy cannot be collected and stored, there is no solution and technical measures, and it cannot achieve high pressure gas production and To achieve the effect of comprehensive utilization and comprehensive treatment promotion, improvement of energy consumption structure, and promotion of national economic development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

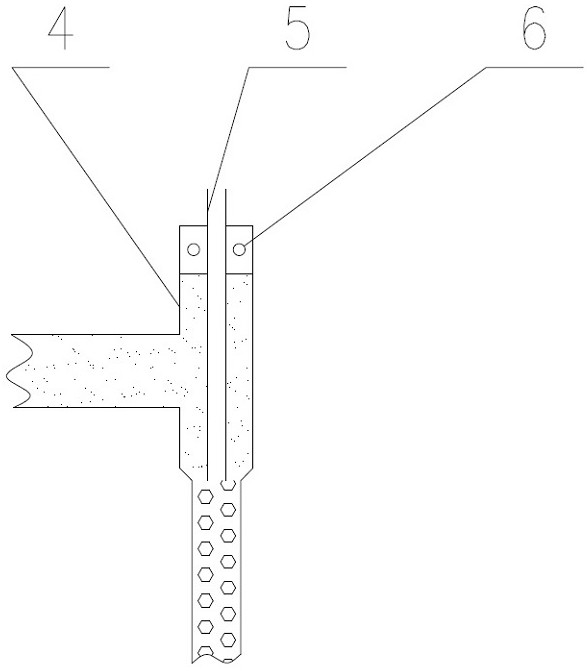

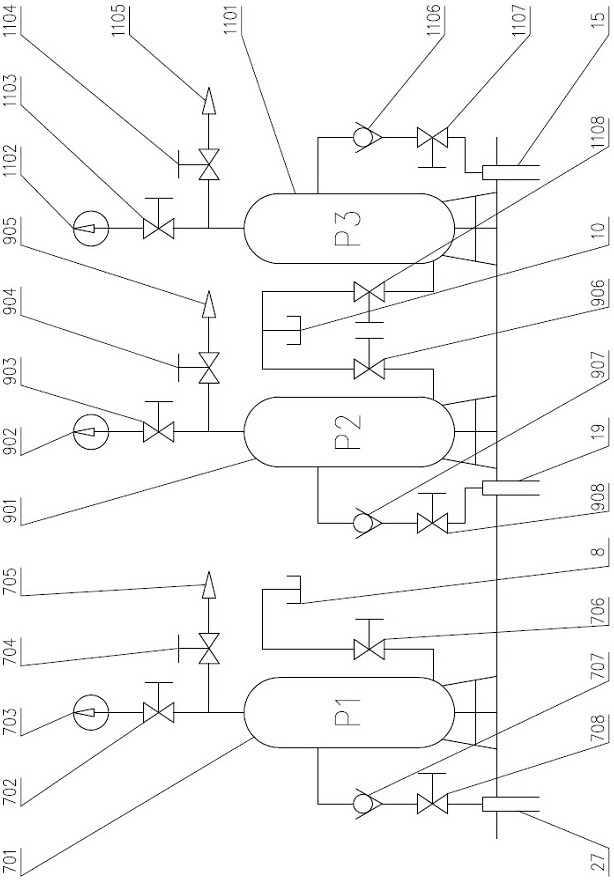

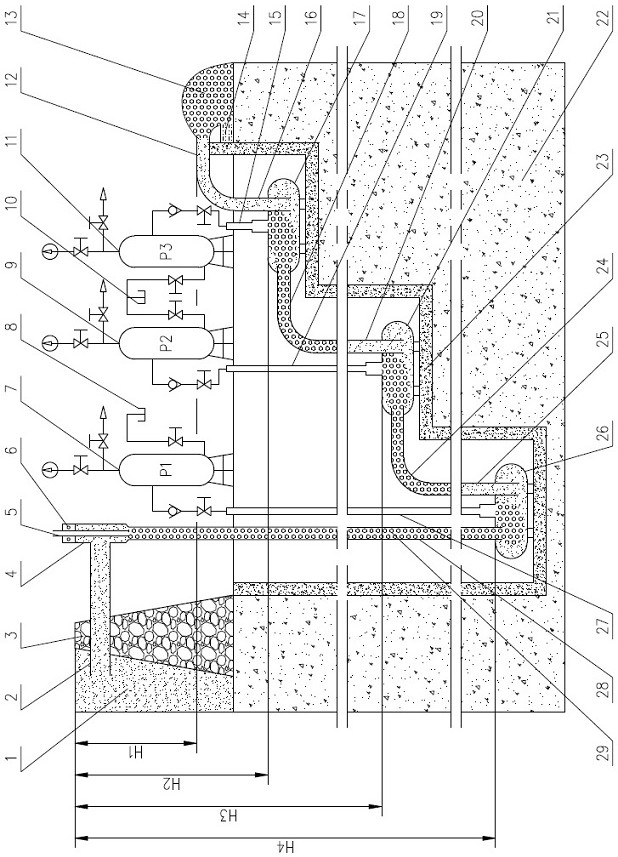

[0022] combine figure 1 , the present invention is a clean energy extraction technology - high-pressure cavitation energy extraction technology, including a horizontal drainage pipe 2, which is connected with a gas-liquid mixing three-way pipe assembly 4, and its lower end is connected with a vertical drainage pipe 28 through a variable diameter, so The lower end of the vertical drainage pipe 28 is connected with the first-level gas-liquid energy conversion tank 26, and the first-level water outlet pipe 25 is installed on the upper right part of the tank body of the first-level gas-liquid energy conversion tank 26. The water inlet pipe 24 is connected, the secondary water inlet pipe 24 is connected with the secondary gas-liquid energy conversion tank 21, and the upper right part of the tank body of the secondary gas-liquid energy conversion tank 21 is installed with a secondary water outlet pipe 20. The water outlet pipe 20 is connected with the tertiary water inlet pipe 18, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com