Non-ideal factor correction system for bridge type sensor

A bridge sensor, non-ideal technology, applied in fluid pressure measurement, instrumentation, climate sustainability, etc. by changing ohmic resistance, can solve the problems of being easily affected by temperature gradients, large area overhead, high cost, etc., and achieve good Temperature drift correction effect, avoiding the effect of large area cost and difficult temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments, which are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

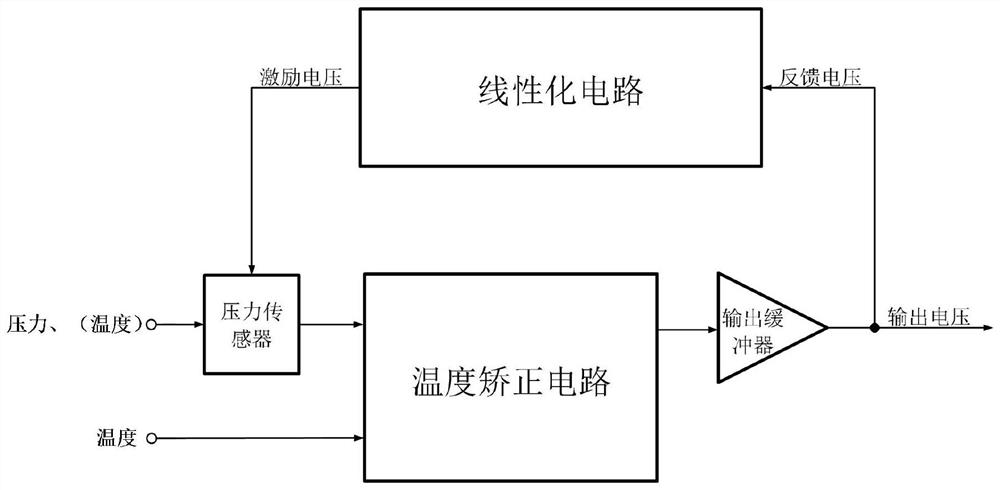

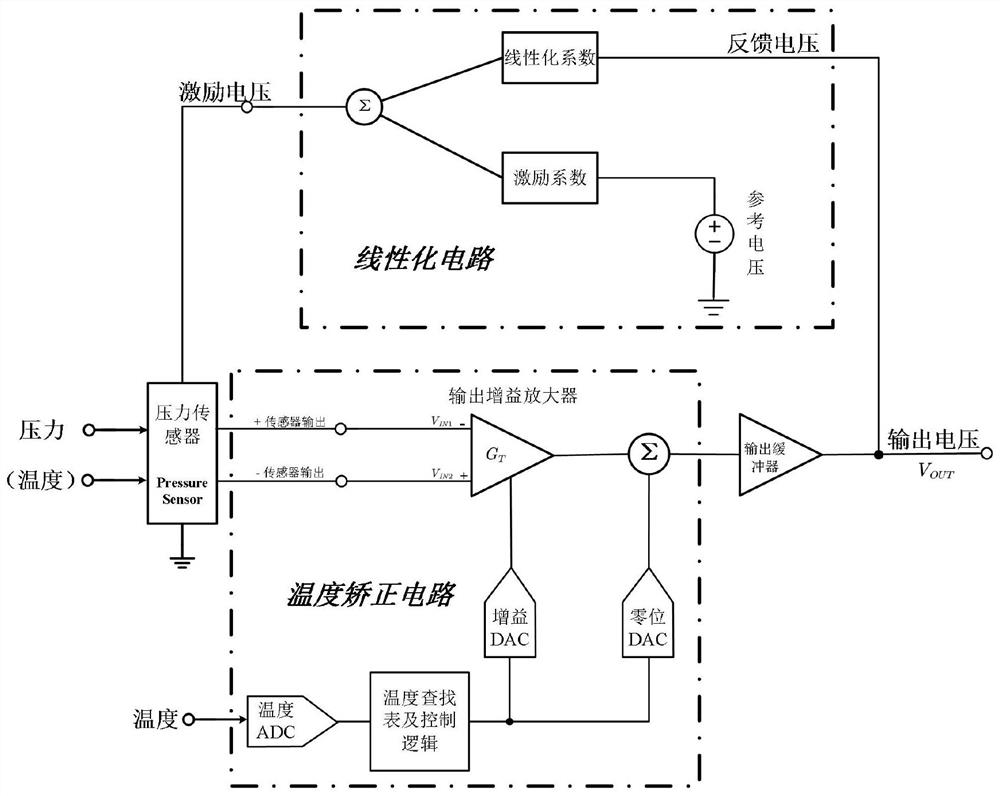

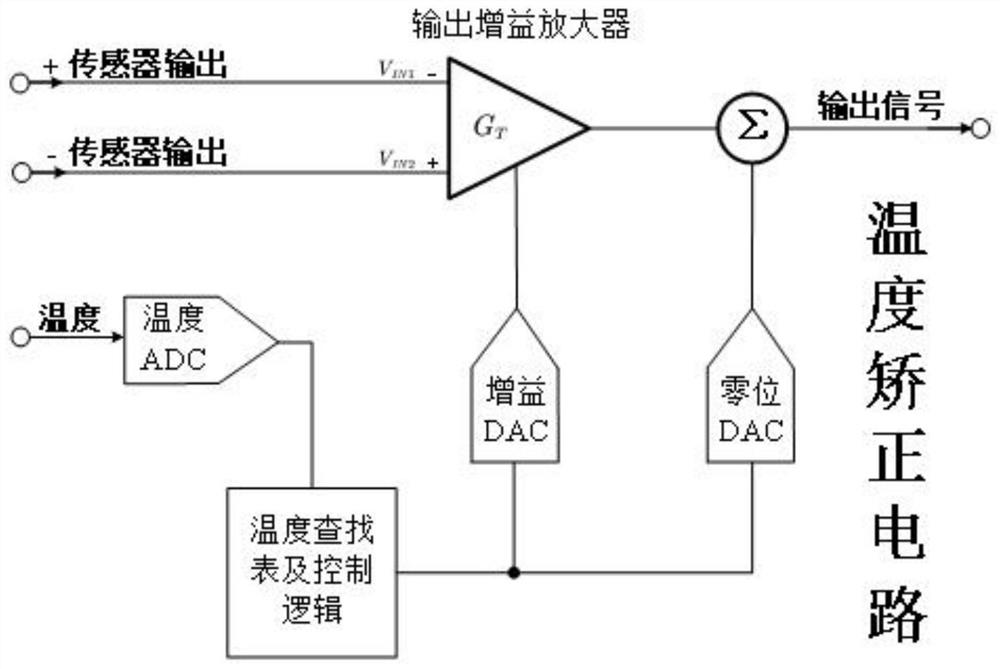

[0032] according to Figure 1-Figure 10 As shown, this embodiment proposes a non-ideal factor correction system for a bridge sensor, including an output buffer for enhancing the load capacity, a linearization circuit for correcting nonlinearity through negative feedback, and A temperature correction circuit for compensating temperature drift, the input end of the temperature correction circuit is connected with the output of the pressure sensor and the external temperature signal, and the temperature correction circuit includes an output gain amplifier, a temperature ADC, a temperature look-up table and a control logic module, The gain DAC, the zero-position DAC and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com