Method for forming bit line air space in semiconductor device manufacturing process

A manufacturing process and air spacing technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical solid-state devices, etc., can solve problems such as bit line damage, and achieve the effect of reducing parasitic capacitance and minimizing pattern damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

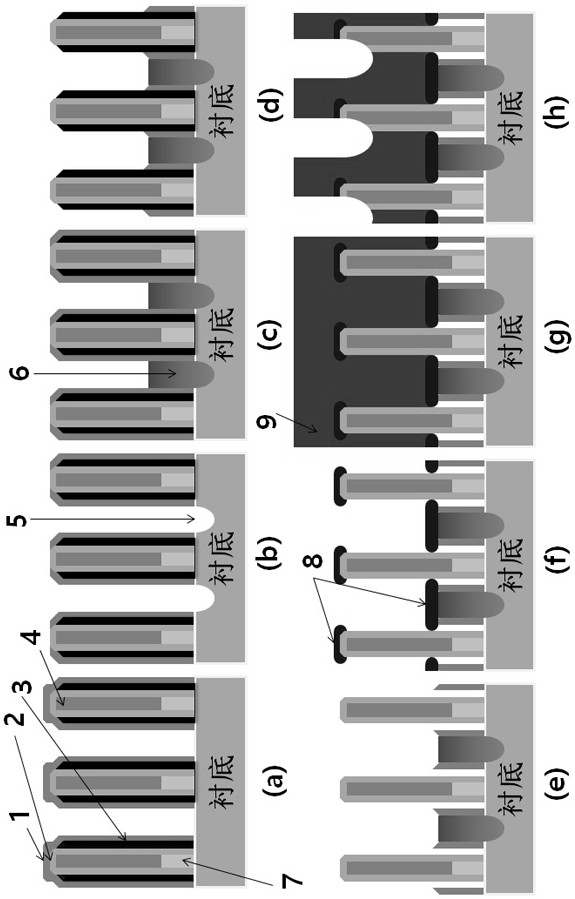

Embodiment 1

[0021] In the process of forming the air space by using the traditional technology, to achieve the technical effect basically equivalent to that of the present invention, it is necessary to ensure that the process conditions of the film etching selection ratio are sufficiently excellent, and the DRAM operation technology that can control the parasitic capacitance is required. It is very difficult to secure a film quality condition with a low dielectric constant that can control parasitic capacitance. Therefore, the present invention proposes a new solution to form air gaps to solve the problems raised in the background art. In a specific implementation process, an embodiment of the present invention provides a method for forming a bit line air spacer in a semiconductor device manufacturing process, including the following steps:

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com