Granular organic matrix device for cultivating orchid and manufacturing method of granular organic matrix device

An organic matrix and granulation technology, which is applied in the direction of planting matrix, culture medium, mold extrusion granulation, etc., can solve the problems of single processing method, inconvenient removal of impurities, and inconvenience for users to replace granulated parts, etc. The effect of stable pressure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and embodiments.

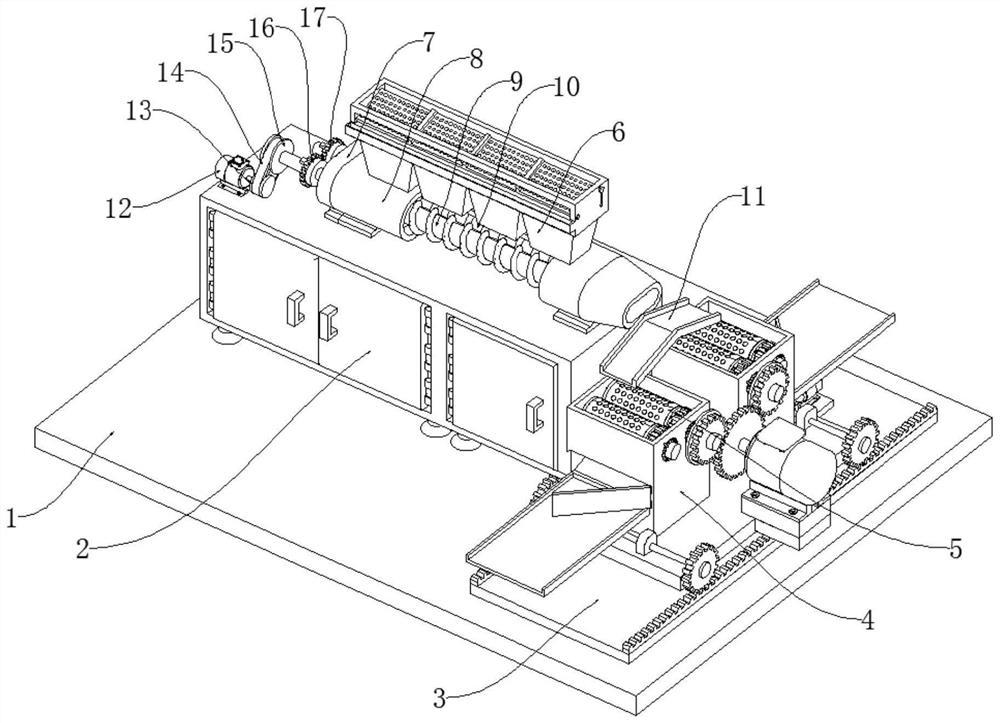

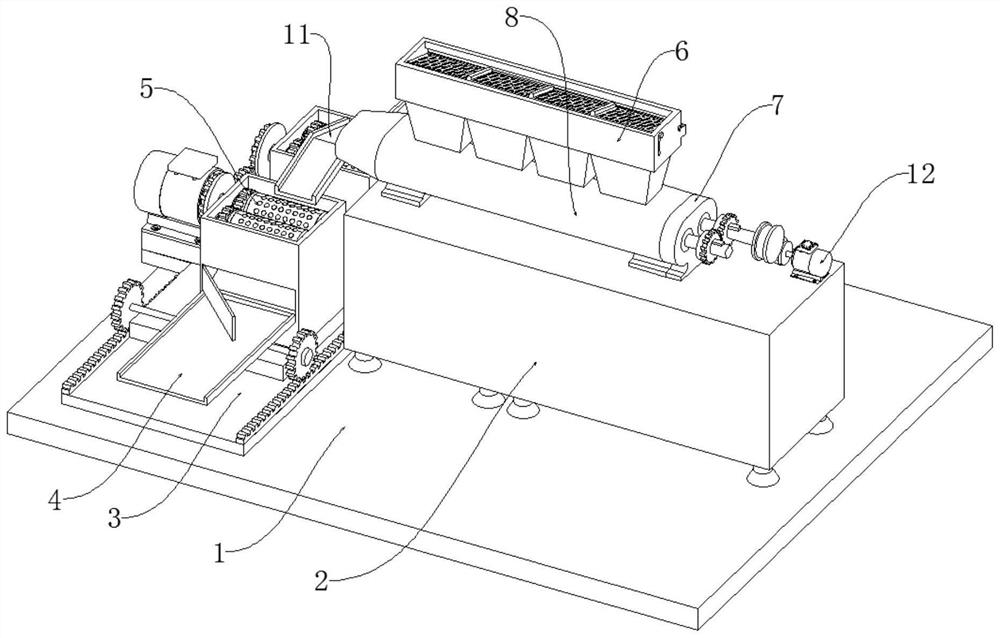

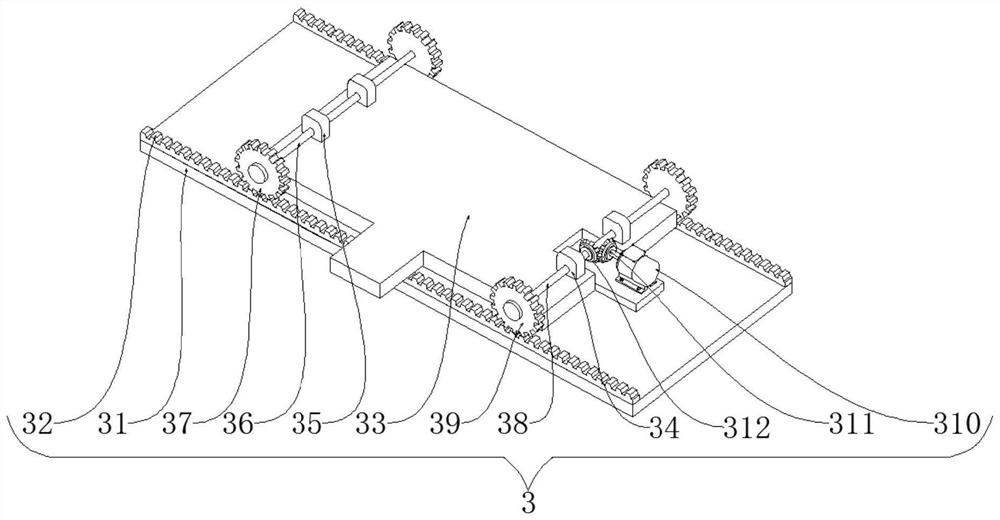

[0035] Please refer to Figure 1 to Figure 6 , a particle organic matrix device for cultivating orchids, comprising a base plate 1, a workbench 2 and a moving mechanism 3 are respectively installed above the base plate 1, a connecting plate 7 and a mixing cylinder 8 are respectively fixed above the workbench 2, and the mixing cylinder is A sorting mechanism 6 is installed above the mixing cylinder 8, a first screw 9 and a second screw 10 are installed inside the mixing cylinder 8, a blanking plate 11 is fixed at the outer end of the mixing cylinder 8, and the upper surface of the worktable 2 is fixed by bolts The hybrid motor 12 is installed, the output shaft keyway of the hybrid motor 12 is connected with the first pulley 13, the outer wall of the first pulley 13 is sleeved with a belt 14, and the inner wall of the belt 14 is located above the first pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com