Appetizing pepper processing technology

A processing technology, green pepper technology, applied in the field of appetizing pepper processing technology, can solve the problems of affecting the quality of processed green pepper products, green peppers are easy to fade green, unfavorable to human health, etc., to achieve fully automatic operation, short pickling time, Good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The appetizer pepper processing technology of the present embodiment, the concrete steps are as follows:

[0041] Step 1), selection: Specifically, choose fresh green peppers with smooth skin and intact pulp;

[0042] Step 2), cleaning: Wash the selected peppers in the usual way and drain the water on the surface of the peppers;

[0043] Step 3), cutting: Cut the green peppers that have been cleaned and drained into two pieces, but are connected near the pedicle, and then remove the seeds;

[0044] Step 4), rolling and kneading: pour the cut green peppers into the conventional rolling and kneading equipment, and add salt to the rolling and kneading equipment. The amount of salt added is 5% of the weight of the fresh green peppers, and the rolling time is 35min;

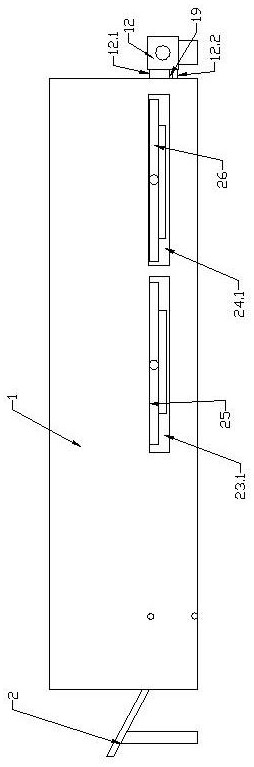

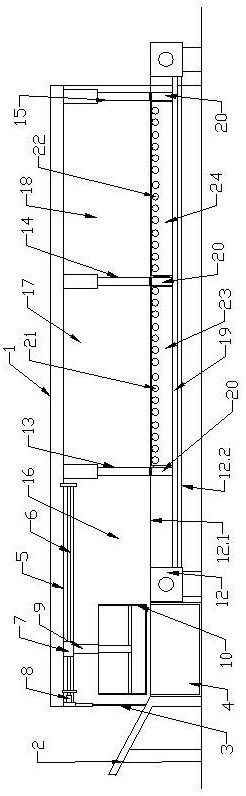

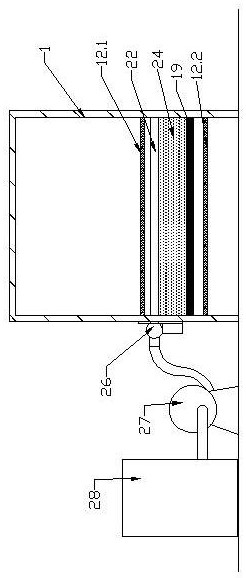

[0045] Step 5), drying: open the first electric lift door 3, pour the tumbled green peppers into the inclined chute 2, and the green peppers slide from the inclined chute 2 into the hanging basket 10 in the b...

Embodiment 2

[0049] The appetizer pepper processing technology of the present embodiment, the concrete steps are as follows:

[0050] Step 1), selection: Specifically, choose fresh green peppers with smooth skin and intact pulp;

[0051] Step 2), cleaning: Wash the selected peppers in the usual way and drain the water on the surface of the peppers;

[0052] Step 3), cutting: Cut the green peppers that have been cleaned and drained into two pieces, but are connected near the pedicle, and then remove the seeds;

[0053] Step 4), rolling and kneading: pour the cut green peppers into the conventional rolling and kneading equipment, and add salt to the rolling and kneading equipment. The amount of salt added is 6% of the weight of the fresh green peppers, and the rolling and kneading time is 35min;

[0054]Step 5), drying: open the first electric lift door 3, pour the tumbled green peppers into the inclined chute 2, and the green peppers are slid from the inclined chute 2 into the hanging bas...

Embodiment 3

[0058] The appetizer pepper processing technology of the present embodiment, the concrete steps are as follows:

[0059] Step 1), selection: Specifically, choose fresh green peppers with smooth skin and intact pulp;

[0060] Step 2), cleaning: Wash the selected peppers in the usual way and drain the water on the surface of the peppers;

[0061] Step 3), cutting: Cut the green peppers that have been cleaned and drained into two pieces, but are connected near the pedicle, and then remove the seeds;

[0062] Step 4), rolling and kneading: pour the cut green peppers into the conventional rolling and kneading equipment, and add salt to the rolling and kneading equipment. The amount of salt added is 6% of the weight of the fresh green peppers, and the rolling and kneading time is 35min;

[0063] Step 5), drying: open the first electric lift door 3, pour the tumbled green peppers into the inclined chute 2, and the green peppers slide from the inclined chute 2 into the hanging baske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com