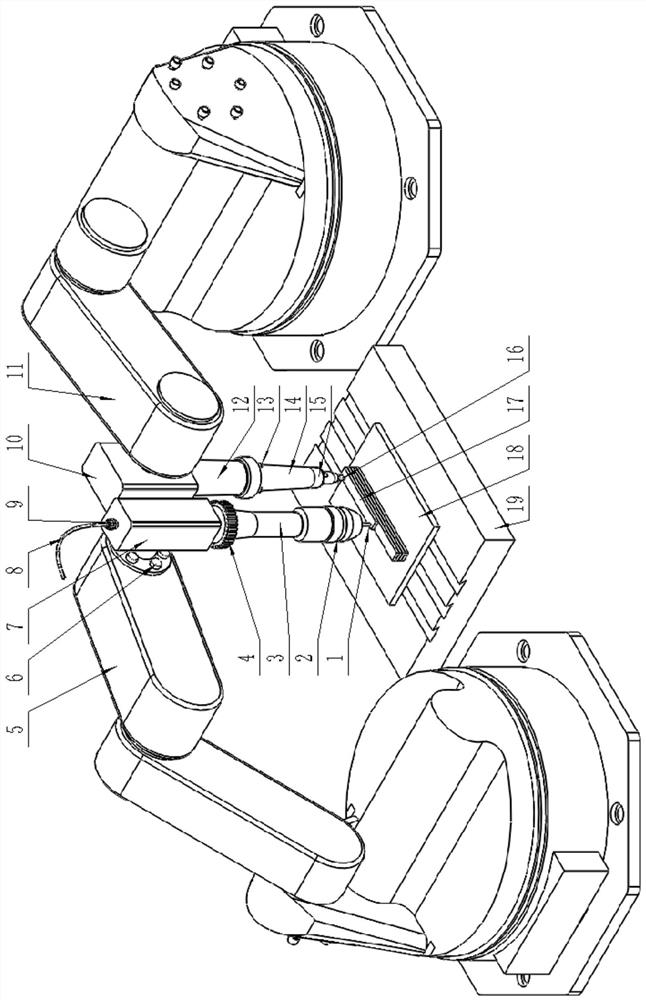

Interlayer ultrasonic peening assisted high-performance CMT electric arc additive manufacturing method and device

A technology of ultrasonic impact and additive manufacturing, applied in the direction of electrode support devices, cleaning methods and appliances, manufacturing tools, etc., can solve the problems of deformation, collapse and growth of formed parts, reduce anisotropy and improve density , Improve the effect of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention are described below to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those skilled in the art, as long as various changes Such changes are obvious within the spirit and scope of the present invention as defined and determined by the appended claims, and all inventions and creations utilizing the inventive concept are within the scope of protection.

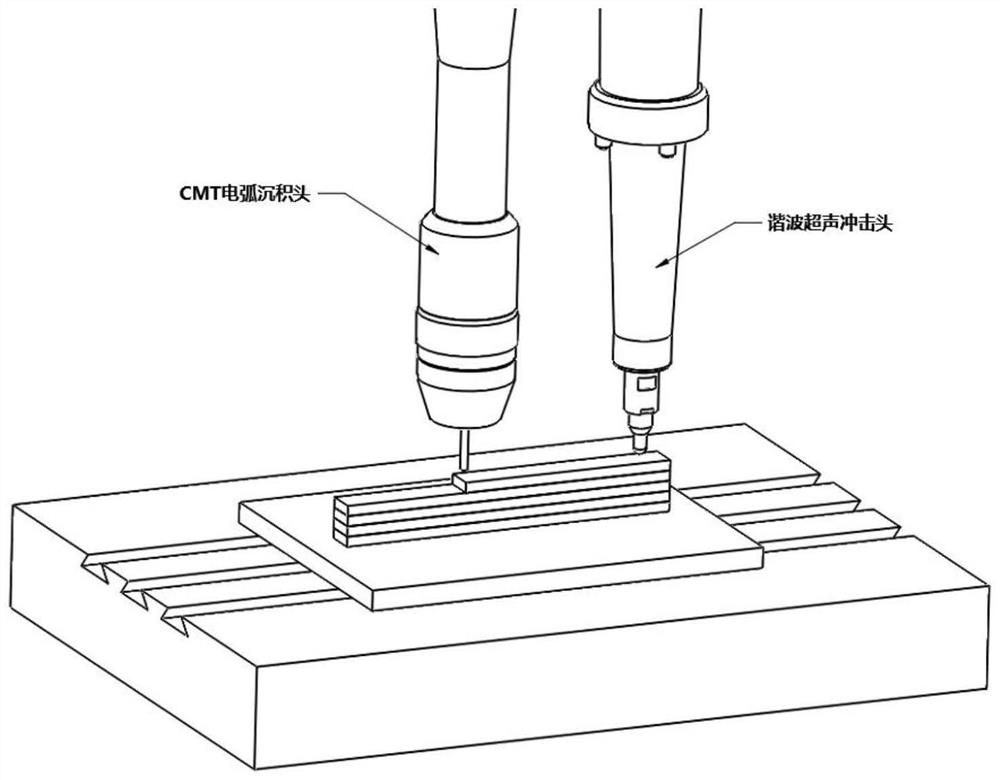

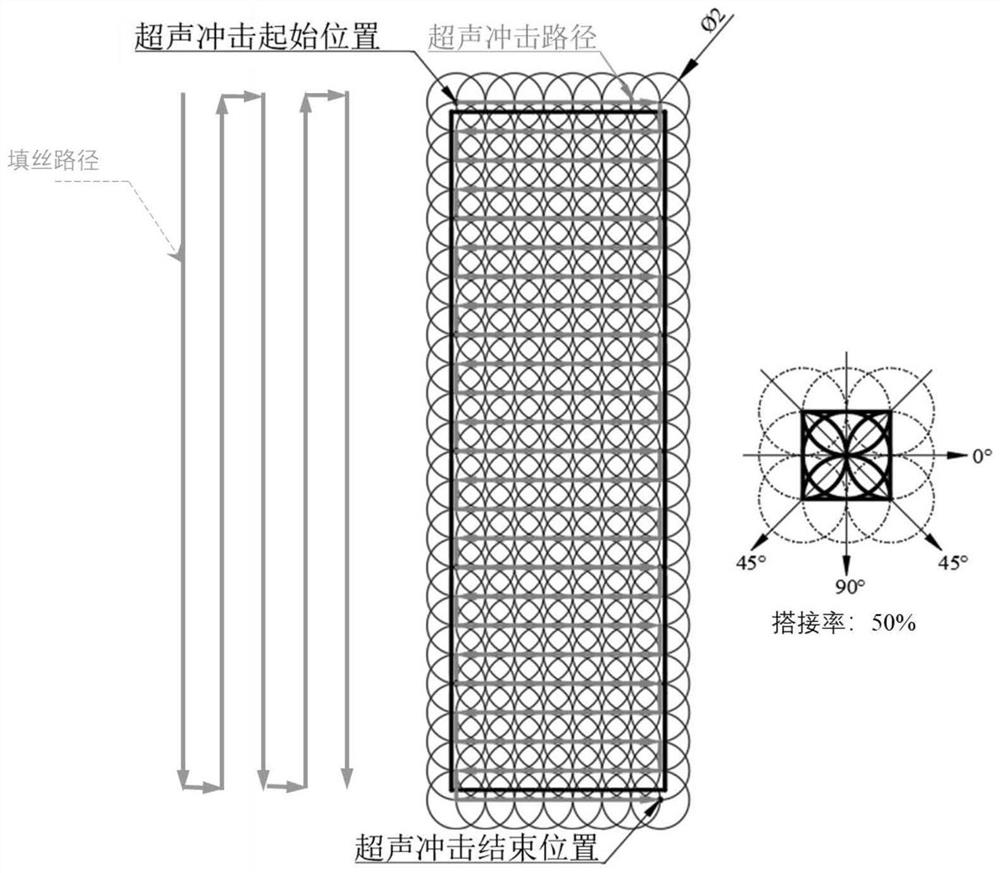

[0025] In the invention, ultrasonic impact treatment is performed on the interlayer bonding interface in the CMT arc additive manufacturing process, so as to eliminate the residual tensile stress at the interface and make the forming surface of the component uniformly plastically deform. The periodicity of equiaxed crystals is uniformly distributed, thereby effectively blocking the growth of coarse columnar β-crystals, improving the anisotr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com