Method for preparing porous microspheres from waste nylon 6 fabric

A technology of waste nylon and porous microspheres, which is applied in the preparation of microspheres, textile/flexible product manufacturing, microcapsule preparation, etc., can solve the problems of small particle size of nylon microspheres, cannot be uniformly distributed, and cannot be formed, and achieves gentle processing. conditions, beneficial to environmental protection and resource utilization, and the effect of high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

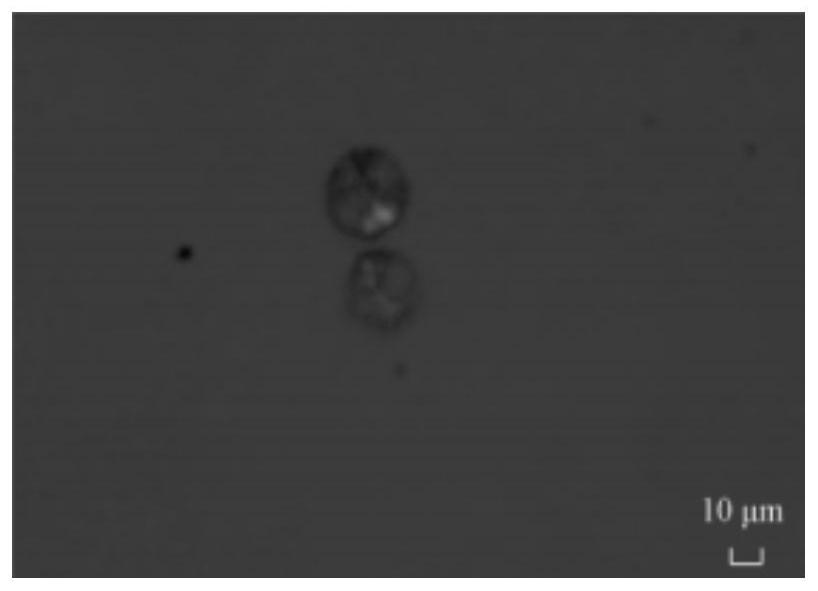

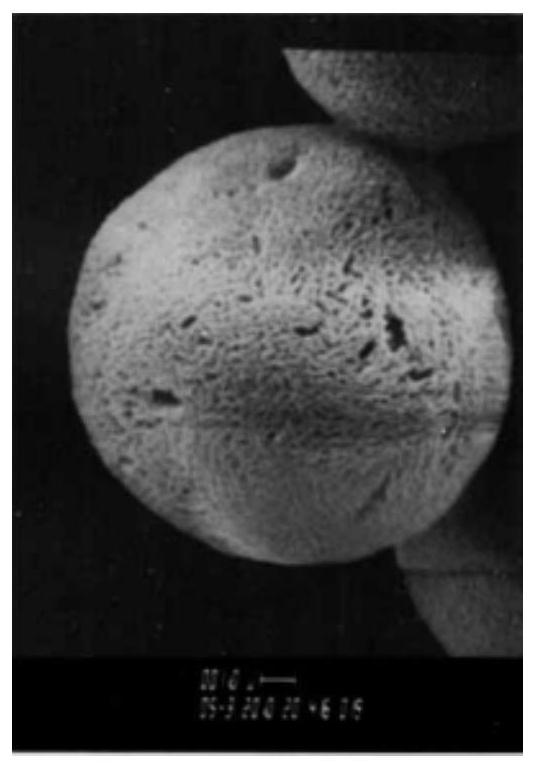

Image

Examples

Embodiment 1

[0056] A method for preparing porous microspheres from waste nylon 6 fabrics, the specific steps are as follows:

[0057] (1) At 25°C, waste nylon 6 fabric (colorless waste nylon 6 fabric fragments, Wujiang Fuhua Weaving Co., Ltd., Suzhou City, Jiangsu Province, weight 100g / cm) 2 ) was immersed in a soaping solution with a concentration of 2g / L, washed for 1 hour, and then dried at 25°C for 24 hours; the bath ratio of waste nylon 6 fabric and soaping solution was 1:50;

[0058] (2) adding the waste nylon 6 fabric after drying in step (1) into anhydrous formic acid, heating and stirring for 2 hours at a temperature of 70 ° C, and filtering to obtain a transparent and uniform nylon 6 solution with a concentration of 5wt%; The pore used in the head is 450nm;

[0059] (3) adding deionized water dropwise to the nylon 6 solution obtained in step (2), the nylon 6 in the nylon 6 solution is separated out; the amount of deionized water added is 80% of the quality of the nylon 6 soluti...

Embodiment 2

[0064] A method for preparing porous microspheres from waste nylon 6 fabrics, the specific steps are as follows:

[0065] (1) At 26 ° C, waste nylon 6 fabric (colorless waste nylon 6 fabric fragments, Wujiang Fuhua Weaving Co., Ltd., Suzhou City, Jiangsu Province, gram weight 100g / cm 2 ) was immersed in soaping solution with a concentration of 2g / L, washed for 1 hour, and then dried at 26°C for 24 hours; the bath ratio of waste nylon 6 fabric and soaping solution was 1:50;

[0066] (2) adding the waste nylon 6 fabric after drying in step (1) into anhydrous formic acid, heating and stirring for 1.8 h at a temperature of 80° C., and filtering to obtain a transparent and uniform nylon 6 solution with a concentration of 5wt%; wherein, filtering The pore used in the filter head is 450nm;

[0067] (3) adding deionized water dropwise to the nylon 6 solution obtained in step (2), the nylon 6 in the nylon 6 solution is separated out; the amount of deionized water added is 80% of the q...

Embodiment 3

[0072] A method for preparing porous microspheres from waste nylon 6 fabrics, the specific steps are as follows:

[0073] (1) At 27 °C, waste nylon 6 fabric (colorless waste nylon 6 fabric fragments, Wujiang Fuhua Weaving Co., Ltd., Suzhou City, Jiangsu Province, gram weight 100g / m2) 2 ) was immersed in soaping solution with a concentration of 2g / L, washed for 1 hour, and then dried at 27°C for 24 hours; the bath ratio of waste nylon 6 fabric and soaping solution was 1:50;

[0074] (2) adding the waste nylon 6 fabric after drying in step (1) into anhydrous formic acid, heating and stirring for 2 hours at a temperature of 80° C., and filtering to obtain a transparent and uniform nylon 6 solution with a concentration of 5wt%; The pore used in the head is 450nm;

[0075] (3) adding deionized water dropwise to the nylon 6 solution obtained in step (2), the nylon 6 in the nylon 6 solution is separated out; the amount of deionized water added is 80% of the quality of the nylon 6 so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com