Powdery emulsion explosive for explosive welding

A technology of powdery emulsion explosives and explosive welding, which is applied in the fields of explosives, explosive composite components, explosive processing equipment, etc., can solve the problems that clay and sensitizers cannot be fully fused and blasting is not guaranteed, and achieve adjustable detonation velocity and easy mixing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

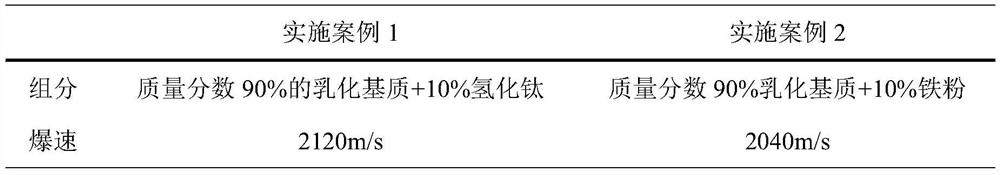

Examples

Embodiment example 1

[0028] St1: Preparation of water phase: add raw material water (8%) and sodium nitrate (7%) into the water phase proportioning tank, stir well under pressure and heating conditions, and then pass the crushed ammonium nitrate (79%) through the transport The hopper is added to the water-phase proportioning tank according to the preset ratio, and after it is completely dissolved, the temperature is kept at 100-110 °C for backup, or it is put into the water-phase storage tank for pressurization and insulation for backup.

[0029] St2: Preparation of oil phase: Paraffin (3%) emulsifier T-152 (2%) light diesel oil (1%) is mixed and added to the oil phase blending tank, under heating conditions, wait for all to melt and reach 90-100 ℃ When the mixture is mixed, it can be put into a mixer to mix evenly for later use, or put into an oil phase storage tank for later use.

[0030] St3: Forming an emulsified matrix: the water phase and the oil phase are respectively filtered by suction an...

Embodiment example 2

[0033] St1: Preparation of water phase: add raw material water (8%) and sodium nitrate (7%) into the water phase proportioning tank, stir well under pressure and heating conditions, and then pass the crushed ammonium nitrate (79%) through the transport The hopper is added to the water-phase proportioning tank according to the preset ratio, and after it is completely dissolved, the temperature is kept at 100-110 °C for backup, or it is put into the water-phase storage tank for pressurization and insulation for backup.

[0034] St2: Preparation of oil phase: Paraffin (3%) emulsifier T-152 (2%) light diesel oil (1%) is mixed and added to the oil phase blending tank, under heating conditions, wait for all to melt and reach 90-100 ℃ When the mixture is mixed, it can be put into a mixer to mix evenly for later use, or put into an oil phase storage tank for later use.

[0035] St3: Forming an emulsified matrix: the water phase and the oil phase are respectively filtered by suction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com