Testing machine with broadband amplitude vibration test/rheological measurement integrated function

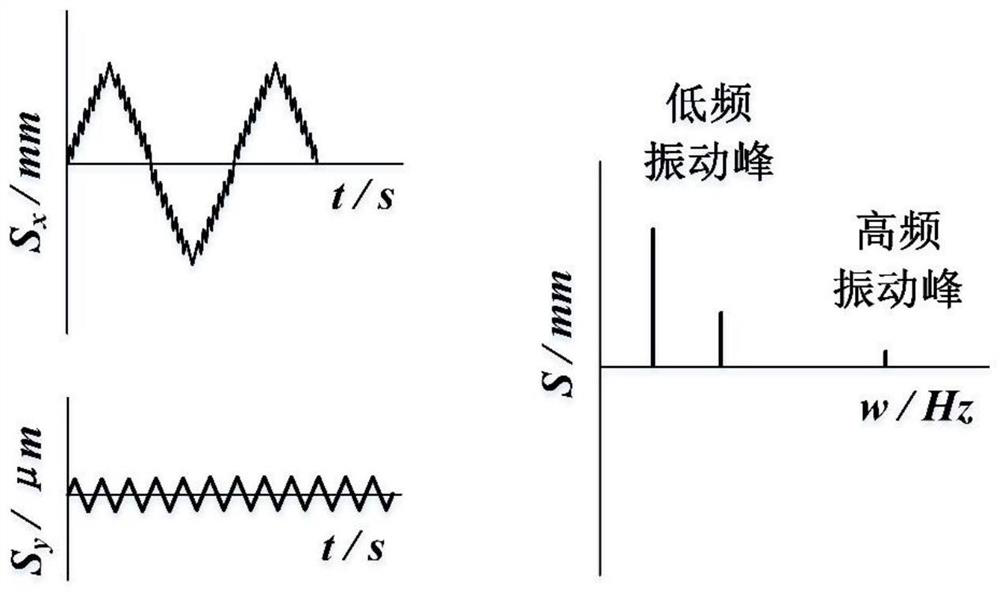

A technology of vibration test and testing machine, which is applied in the field of polymer fine structure manufacturing, can solve the problems of inability to reveal the rules of competition and synergy of multiple vibration modes, inability to discover new phenomena of polymer molecular orientation and disentanglement, inability to obtain flow Change new data and other issues to achieve the effect of improving processing efficiency and mechanical properties, short processing time and wide frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

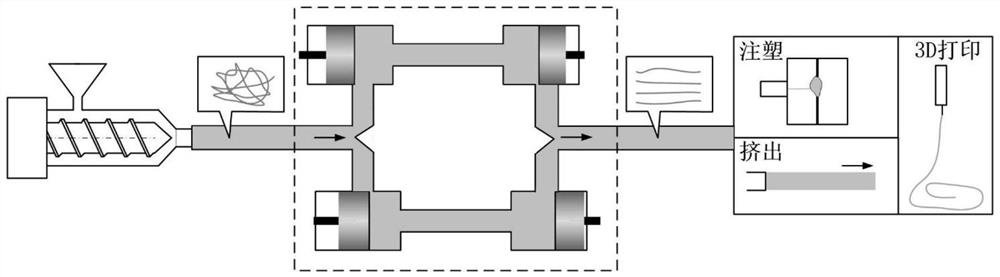

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below according to the accompanying drawings and preferred embodiments, and the purpose and effects of the present invention will become clearer.

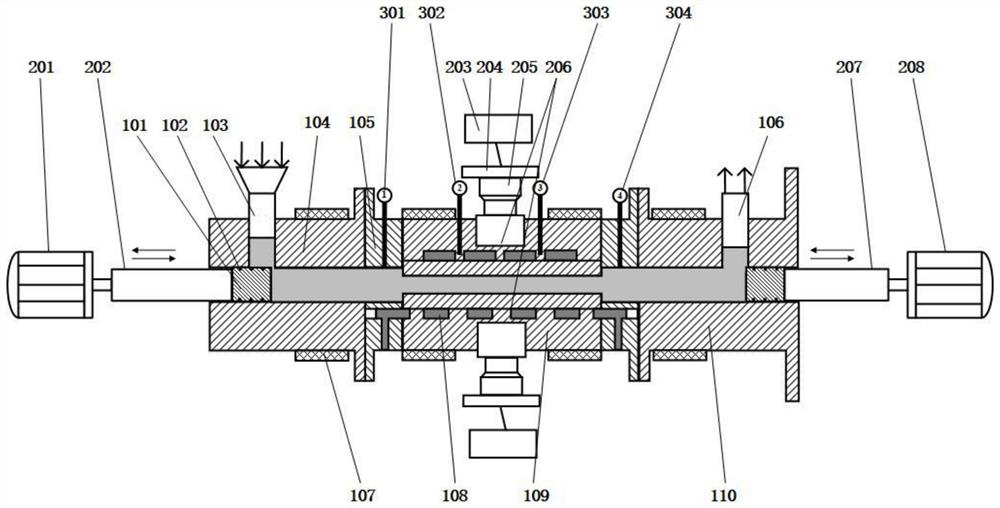

[0036] The mold assembly includes a piston 101 , a sealing ring 102 , an inlet 103 , a left mold 104 , a mold jacket 105 , an outlet 106 , a heating coil 107 , a cooling water channel 108 , a center mold 109 , and a right mold 110 . The left mold 104 , the center mold 109 , and the right mold 110 adopt a combined structure, and the mold jacket 105 is used for combined assembly between the left mold 104 and the center mold 109 , and the center mold 109 and the right mold 110 . The left mold 104 , the mold jacket 105 , the center mold 109 , and the right mold 110 are provided with mold cavities inside. The inner diameter of a section of the channel located inside the center mold 109 in the mold cavity is between several micrometers and several millimeters, and the aspect ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com