Inter-flow temperature difference prediction method and structure optimization method for multi-flow tundish

A technology of prediction method and optimization method, applied in the direction of design optimization/simulation, instruments, manufacturing tools, etc., can solve the problems of cumbersome prediction process, finding the optimal solution, disadvantage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

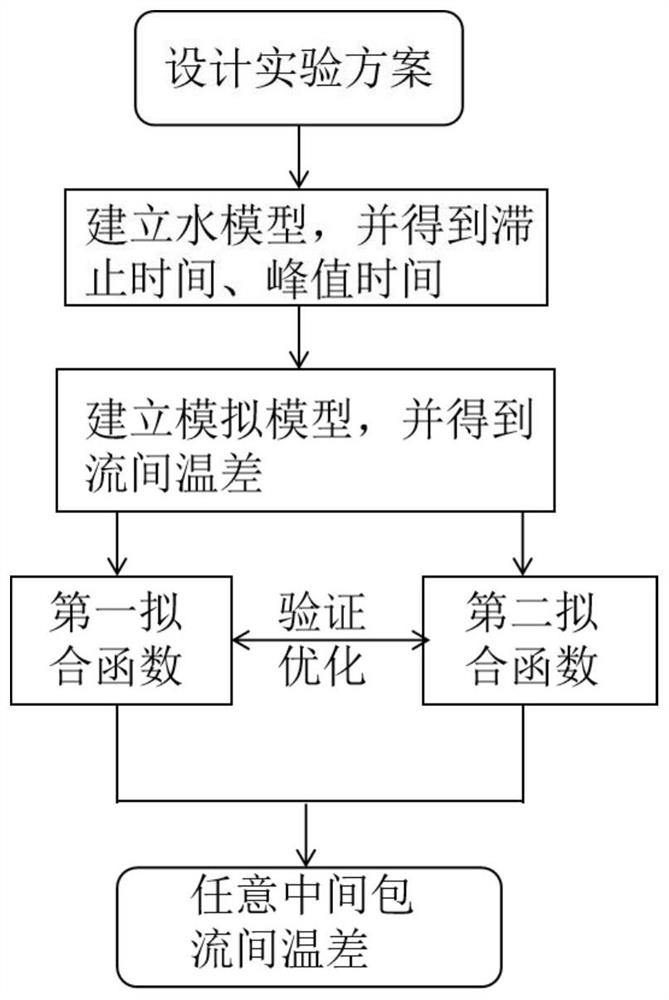

[0055] like figure 1 As shown, the temperature difference prediction method includes the following steps:

[0056] S102. Design the experimental scheme of the inner structure of the tundish;

[0057] The purpose of this step is to provide real and effective experimental data for subsequent function fitting. Since the dam mainly affects the flow of molten steel in the tundish, the optimization scheme takes the dam of the tundish as a parameter variable. And in order to improve the accuracy of the later function fitting results, it is necessary to set multiple sets of reasonably dispersed parameter values.

[0058] This embodiment is specifically carried out on a seven-machine seven-strand continuous casting equipment, the width of the dam is 120-450 mm, and the height of the dam is 100-400 mm. Therefore, when designing the experimental scheme, multiple sets of experimental parameter values are taken at equal intervals of 50 mm within this range.

[0059] S104, establish a...

Embodiment 2

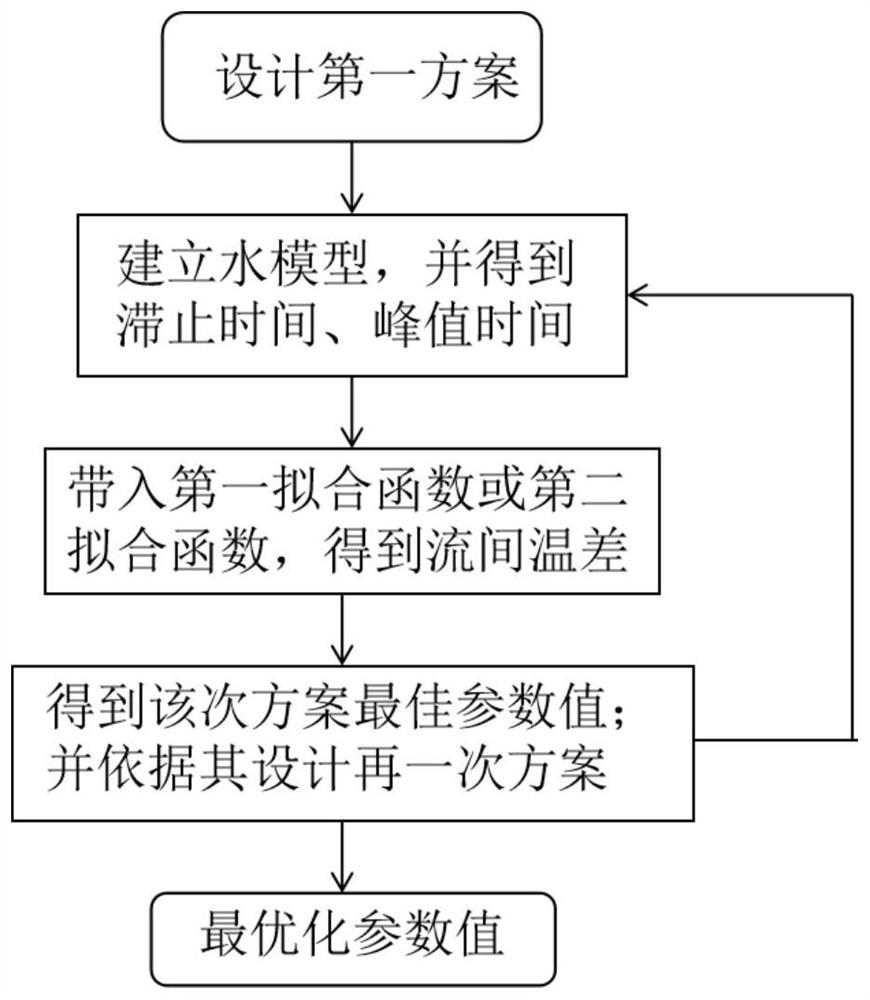

[0085] Based on the first fitting function and the second fitting function obtained above, the prediction of the temperature difference between the intermediate flow and the edge flow of the seven-machine seven-strand continuous casting equipment is carried out, and the specific steps are as follows:

[0086] First, set up an optimization plan to keep the slag retaining wall in the tundish inner structure unchanged, and set up 3 and 4 flow retaining dams with a height of 200mm and a width of 450mm;

[0087] Secondly, the water model experiment with the similarity ratio λ=0.51 is carried out, and the stagnation time under the water model is obtained as t 1 = 84; peak time is t 2 =158;

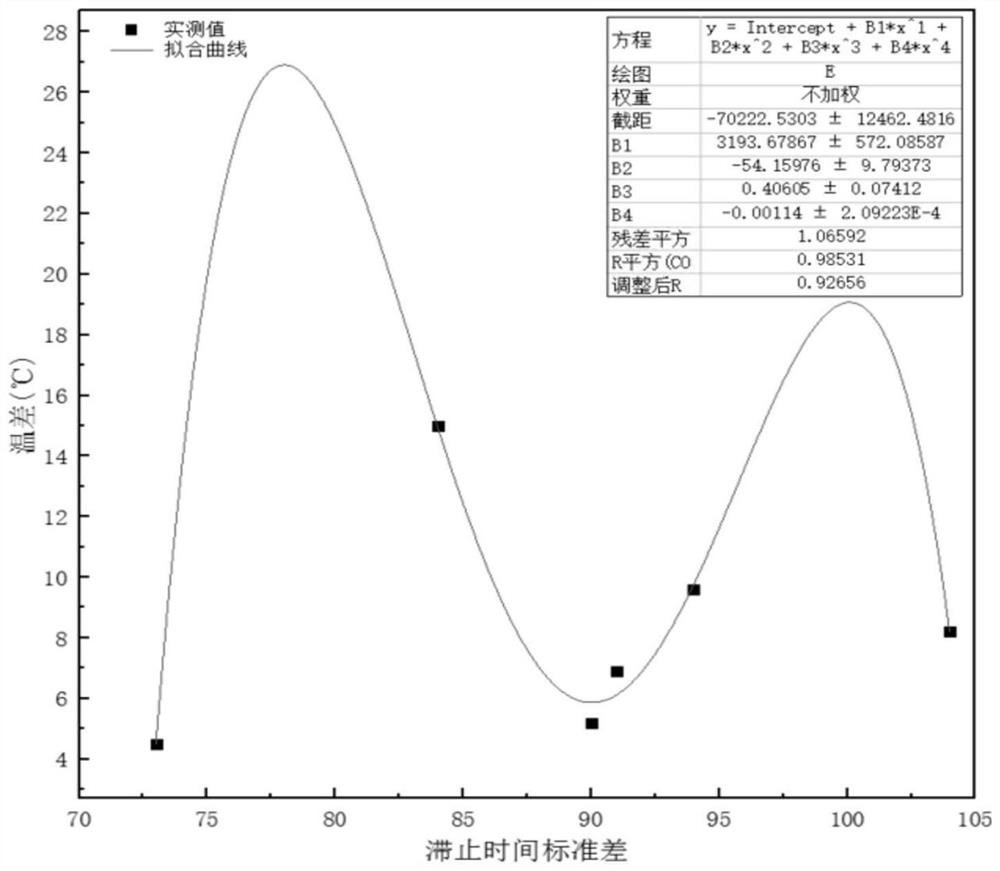

[0088] Finally, set the stagnation time t 1 =84 is substituted into y=a 4 t 1 4 +a 3 t 1 3 +a 2 t 1 2 +a 1 t 1 +a 0 , where a 4 is -0.00114, a 3 is 0.40605, a 2 is -54.15976, a 1 is 3193.67867, a 0 is -70222.5303; the temperature difference between the intermediate flow and th...

Embodiment 3

[0091] Based on the first fitting function and the second fitting function obtained above, the prediction of the temperature difference between the intermediate flow and the edge flow of the seven-machine seven-strand continuous casting equipment is carried out, and the specific steps are as follows:

[0092] First, set the optimization plan to keep the slag retaining wall unchanged in the tundish inner structure. The 3rd and 4th stream dams are set with a height of 400mm and a width of 120mm, and the 2nd and 3rd streams are set with a height of 200mm and a width of 120mm. Dam;

[0093] Secondly, carry out the water model experiment with the similarity ratio λ=0.51, and obtain the stagnation time t under the water model 1 =90; peak time t 2 =103;

[0094] Finally, set the stagnation time t 1 =90 is substituted into y=a 4 t 1 4 +a 3 t 1 3 +a 2 t 1 2 +a 1 t 1 +a 0 , where a 4 is -0.00114, a 3 is 0.40605, a 2 is -54.15976, a 1 is 3193.67867, a 0 is -70222.5303...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com