Hydrogenation catalyst, preparation method and application thereof, and preparation method of cyclohexyl formic acid

A technology of hydrogenation catalyst and auxiliary agent, which is used in catalyst activation/preparation, ozone oxidation to prepare carboxylic acid, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of high unit consumption of precious metal catalyst, high separation difficulty, Reaction selectivity decline and other problems, to achieve the effect of continuous and stable operation, continuous and convenient operation, and improve catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

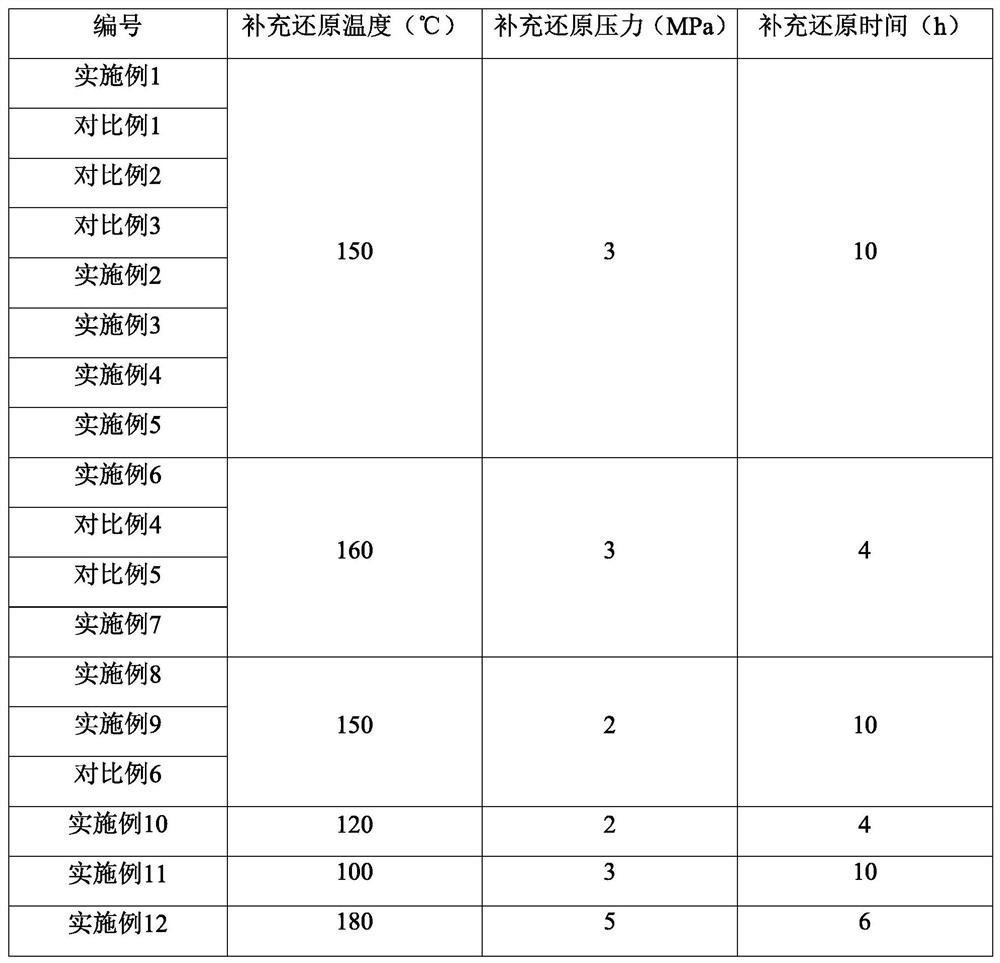

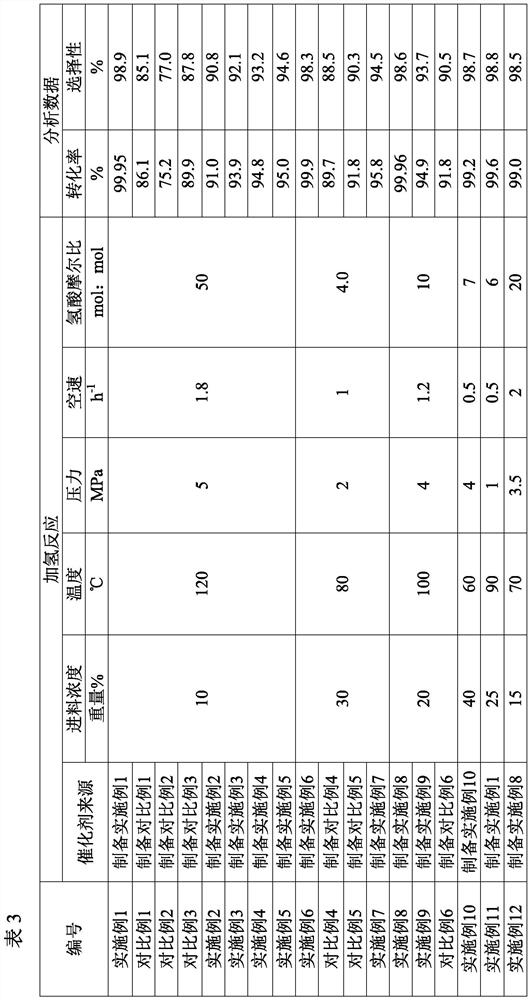

Examples

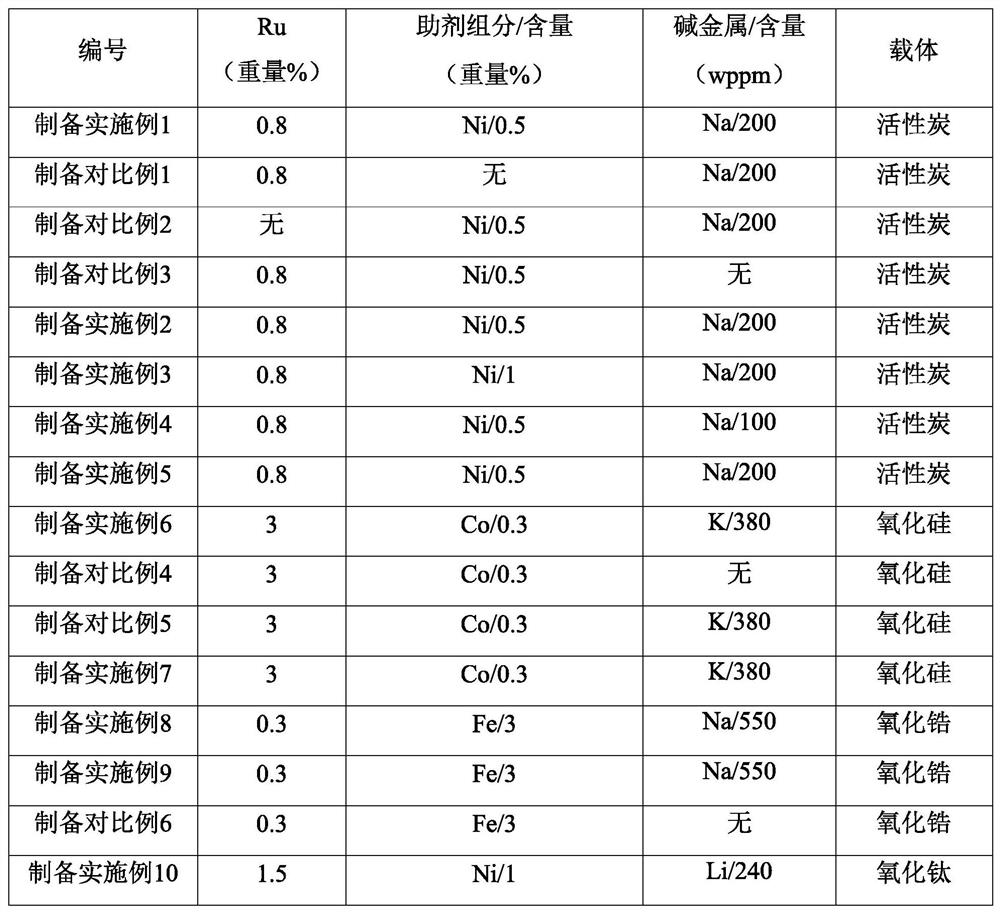

preparation example Construction

[0031] The preparation method according to the present invention includes step (2): contacting the modified carrier with a solution containing the precursor of the active component and the precursor of the auxiliary component to obtain the precursor loaded with the active component and the auxiliary component The supported carrier of the precursor is calcined after removing at least part of the volatile components in the supported carrier to obtain a hydrogenation catalyst precursor.

[0032] In step (2), the active component is ruthenium. In the present invention, the term "active component precursor" refers to a substance that can form an active component in the catalyst during the catalyst preparation process. The active component precursor is preferably one or more of ruthenium chloride, ruthenium nitrate and ruthenium acetate. The auxiliary components are one or more of nickel, iron and cobalt. In the present invention, the term "auxiliary component precursor" refers to...

preparation Embodiment 1

[0065] (1) At a temperature of 20 °C, impregnated activated carbon (purchased from Shenhua Group, with a specific surface area of 950 m) with 25 mL of sodium hydroxide aqueous solution 2 / g) for 2 hours, then the impregnated activated carbon was washed with deionized water until the pH value of the washed water was 7.2, and then the washed solid matter was dried at 100° C. for 10 hours to obtain a modified carrier.

[0066] (2) At a temperature of 50 °C, use 25 mL of RuCl 3 and NiCl 2 The modified carrier prepared in step (1) was impregnated with the aqueous solution for 15 hours, and the impregnated modified carrier was dried at 80°C for 20h, and then calcined in an air atmosphere at 180°C for 10h to obtain a catalyst precursor. Wherein, in the aqueous solution that step (2) adopts, RuCl 3 The concentration is 3.68×10 -5 mol / mL, NiCl 2 The concentration is 3.45×10 -5 mol / mL, the molar ratio of the NaOH used in step (1) to the total amount of Ru and Ni in step (2) is 3:...

preparation Embodiment 2

[0075] The hydrogenation catalyst was prepared by the same method as in Preparation Example 1, except that in step (2), the calcination was carried out at a temperature of 300°C. The compositions of the prepared hydrogenation catalysts are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com