Automatic production line for blow molding of plastic bottles

An automatic production line and plastic bottle technology, which is applied in the field of blow molding machines, can solve the problems of being unable to adapt to the continuous feeding speed, continuous flipping and feeding, difficulty in controlling the uniform heating inside and outside the preform, and high requirements for the preform heating process to achieve continuous Preheating operation, docking transfer is smooth and efficient, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

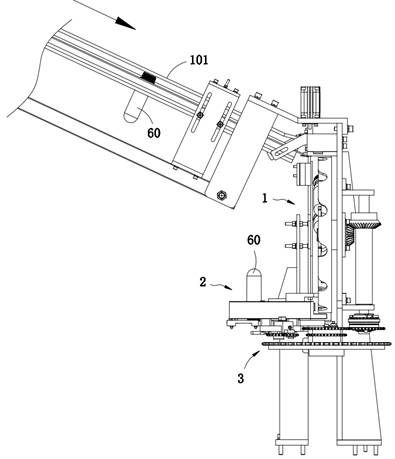

[0045] Preferably, the bottle body heating lamp group 42 includes: several groups of lamp tubes 420 covering the height distribution of the bottle body of the preform 60, such as Figure 9 As shown, the side of the lamp tube 420 facing the heating delivery channel 410 is set as a light-transmitting structure 421 , and the side of the lamp tube 420 facing away from the heating delivery channel 410 is set as a light-reflecting structure 422 .

[0046] Preferably, the directional preheating unit 4 further includes: a bottle finish cooling mechanism 44 installed on the heating box 41 below the bottle body heating lamp group 42 .

[0047] In this embodiment, a reflector 43 is provided on the side of the heating box 41 opposite to the bottle body heating lamp group 42. After the heat energy generated by the bottle body heating lamp group 42 is output, it can be fully reflected to the body of the bottle through the reflector 43, reducing The heat is dissipated, and the structure of t...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com