Preparation method of one-steel multi-stage titanium microalloyed structural steel

A technology of micro-alloying and structural steel, which is applied in the field of metallurgy, can solve the problems of simultaneous production of multi-grade steel, etc., and achieve the effects of ensuring strength, reducing the amount of addition, and improving low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

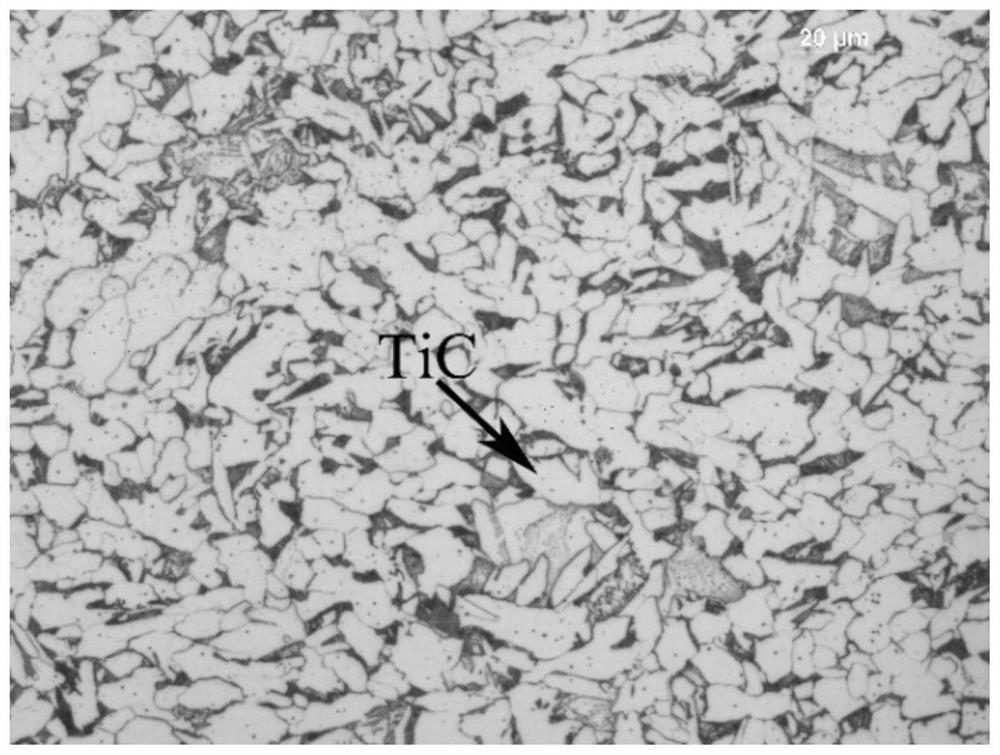

Image

Examples

Embodiment 1

[0024] The preparation method of one-steel multi-level titanium microalloyed structural steel according to the present invention comprises the following steps:

[0025] (1) Smelting and casting

[0026] Chemical composition design: C 0.18%, Si 0.18%, Mn 0.350%, Ti 0.04%, P 0.011%, S0.012%, Alt 0.018%, CEV 0.23%, the balance is Fe and other inevitable impurities; will be as above The chemical composition is converted into a steel billet by converter smelting and casting, and the thickness of the steel billet is 230mm;

[0027] (2) Heating and hot rolling

[0028] The billet obtained in step (1) is heated, the temperature of the soaking section is set to 1230 ° C, and the soaking time is 40 minutes; rough rolling and finishing rolling are used for hot rolling, and the pass distribution of the rough rolling mill and the finishing rolling mill and the reduction ratio of each pass are changed from two. The rough rolling setting model of the grade system is calculated, the rough r...

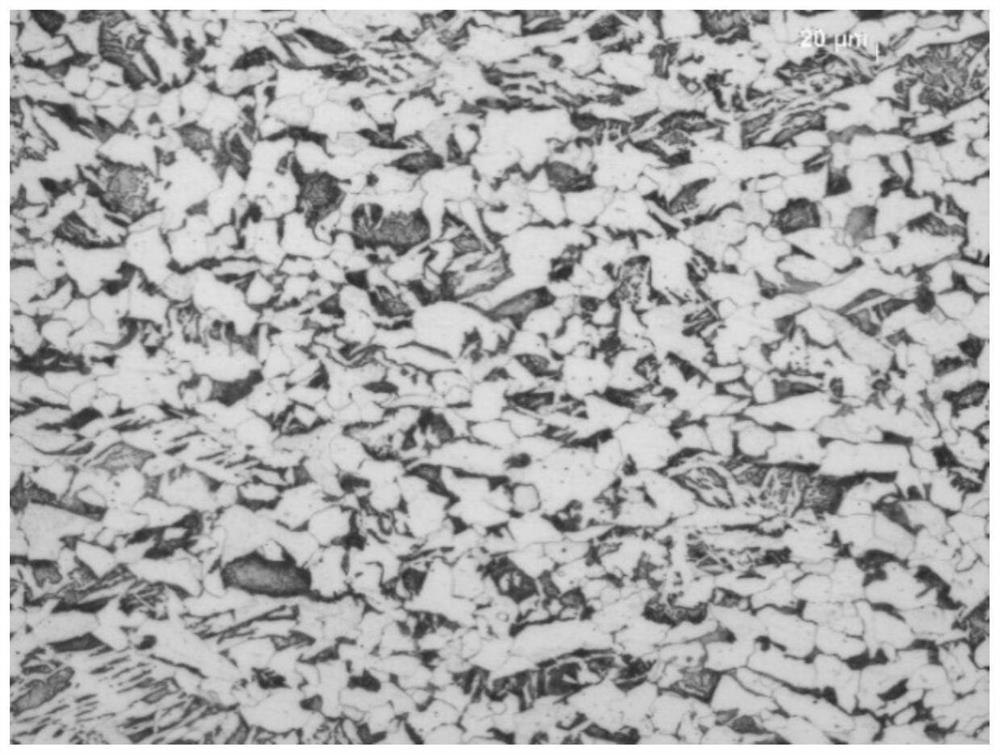

Embodiment 2

[0034] The preparation method of one-steel multi-level titanium microalloyed structural steel according to the present invention comprises the following steps:

[0035] (1) Smelting and casting

[0036] Chemical composition design: C 0.19%, Si 0.19%, Mn 0.30%, Ti 0.04%, P 0.013%, S0.010%, Alt 0.019%, CEV 0.24%, the balance is Fe and other inevitable impurities; will be as above The chemical composition is converted into a steel billet by converter smelting and casting, and the thickness of the steel billet is 230mm;

[0037] (4) Heating and hot rolling

[0038] The billet obtained in step (1) is heated, the temperature of the soaking section is set to 1230 ° C, and the soaking time is 40 minutes; rough rolling and finishing rolling are used for hot rolling, and the pass distribution of the rough rolling mill and the finishing rolling mill and the reduction ratio of each pass are changed from two. The rough rolling setting model of the grade system is calculated, the rough ro...

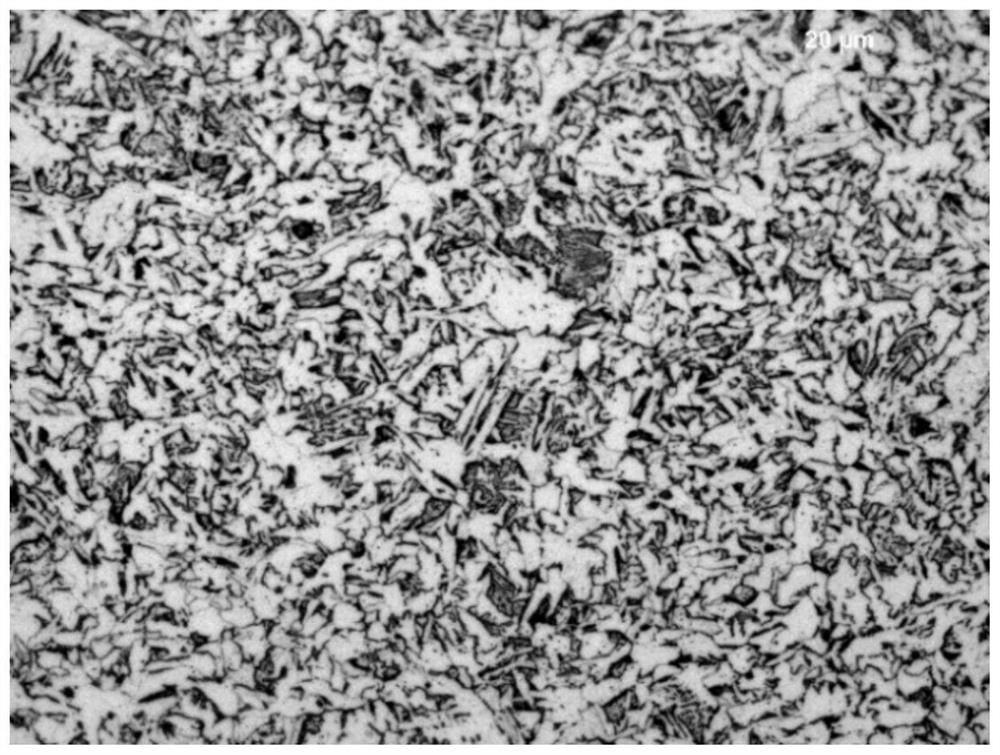

Embodiment 3

[0044] The preparation method of one-steel multi-level titanium microalloyed structural steel according to the present invention comprises the following steps:

[0045] (1) Smelting and casting

[0046] Chemical composition design: C 0.20%, Si 0.21%, Mn 0.32%, Ti 0.04%, P 0.011%, S0.009%, Alt 0.017%, CEV 0.25%, the balance is Fe and other inevitable impurities; will be as above The chemical composition is converted into a steel billet by converter smelting and casting, and the thickness of the steel billet is 230mm;

[0047] (6) Heating and hot rolling

[0048] The billet obtained in step (1) is heated, the temperature of the soaking section is set to 1230 ° C, and the soaking time is 40 minutes; rough rolling and finishing rolling are used for hot rolling, and the pass distribution of the rough rolling mill and the finishing rolling mill and the reduction ratio of each pass are changed from two. The rough rolling setting model of the grade system is calculated, the rough ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com