Magnetic conductive material, preparation method thereof and cooking utensil containing magnetic conductive material

A technology of magnetic conductive material and ceramic material, applied in the direction of magnetic material, inorganic material magnetic, inductance/transformer/magnet manufacturing, etc., can solve the problems of loose bonding, high cost, large electromagnetic noise, etc., and achieve strong plastic deformation resistance. , Low Curie temperature, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] According to the present invention, in some embodiments, there is also provided a method for preparing a magnetically conductive material, comprising the following steps:

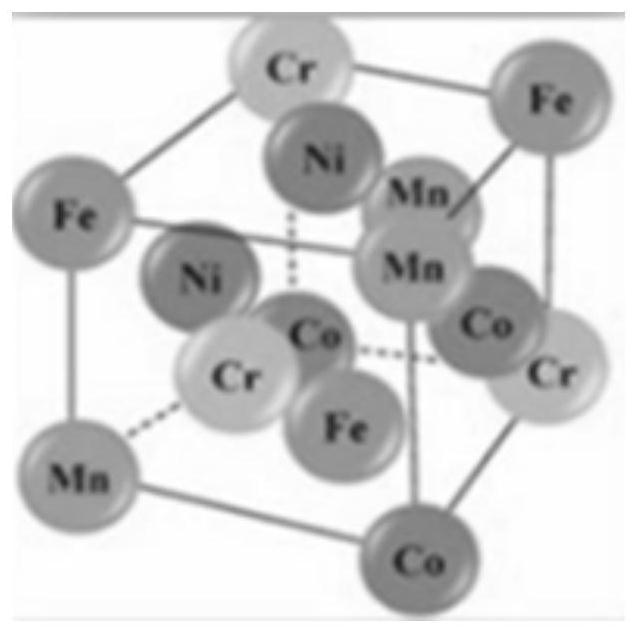

[0083] Mixing the high-entropy alloy and the filler, and granulating to obtain the magnetically permeable material;

[0084] Wherein, the constituent elements of the high-entropy alloy include Mg, Al, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Sn, Hf, Ta, W, Pb, Si and at least four of B, and the constituent elements include at least one or more of Fe, Co and Ni;

[0085] The filler includes at least one of inorganic porous materials and ceramic materials.

[0086] In the preparation method, the mixed powder including high-entropy alloy and filler is used for mixing, and the magnetic conductive material obtained by granulation has excellent magnetic permeability, can realize electromagnetic induction heating, and has uniform heat generation during use, Constant temperature, can reduce or avoid ...

Embodiment 1

[0131] A magnetic conductive material, comprising a high-entropy alloy and diatomite, wherein the high-entropy alloy is AlCr 2 Fe 3 Co 3 Ni 2 , the content of diatomite is 5% of the mass of the magnetic conductive material.

[0132] The particle size of the magnetic conductive material is 200 meshes to 300 meshes.

Embodiment 2-5

[0134] The main difference between Examples 2-5 and Example 1 is the type of high-entropy alloy.

[0135] In Example 2, the high-entropy alloy is AlCrFe 2 CoNi 3 Cu;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com