Spiral climbing robot for wind power generation tower

A robot and spiral technology, which is applied in the field of wind power tower spiral climbing robots, can solve the problems of peeling and rusting of shell paint, low work efficiency, deepening corrosion, etc., and achieve the effects of simplified machine structure, simple and compact structure, and small rotational torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

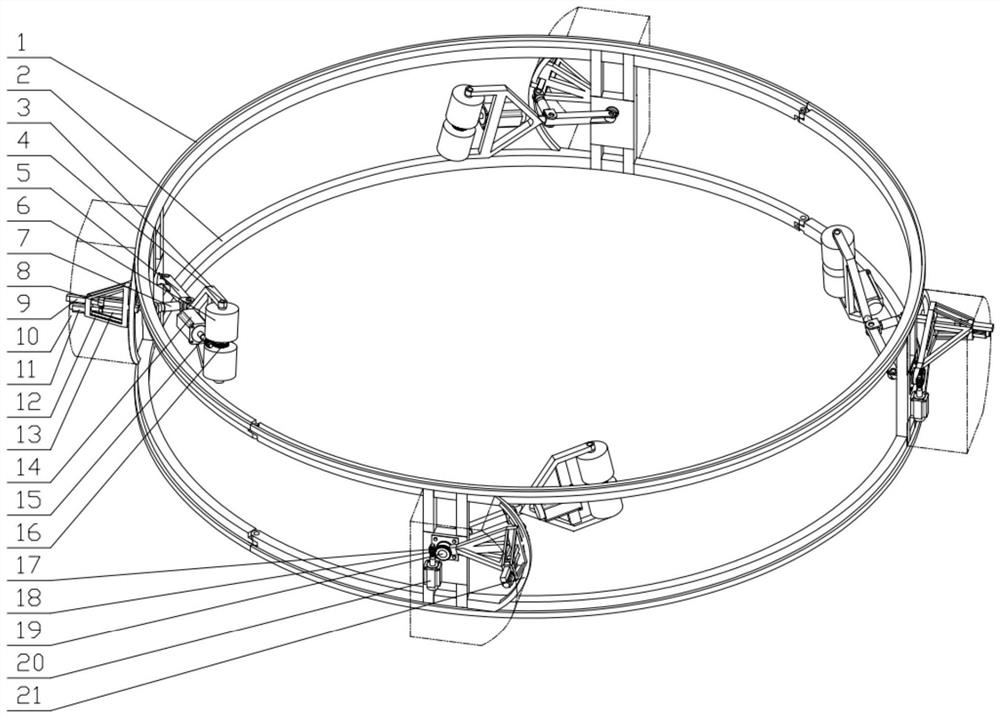

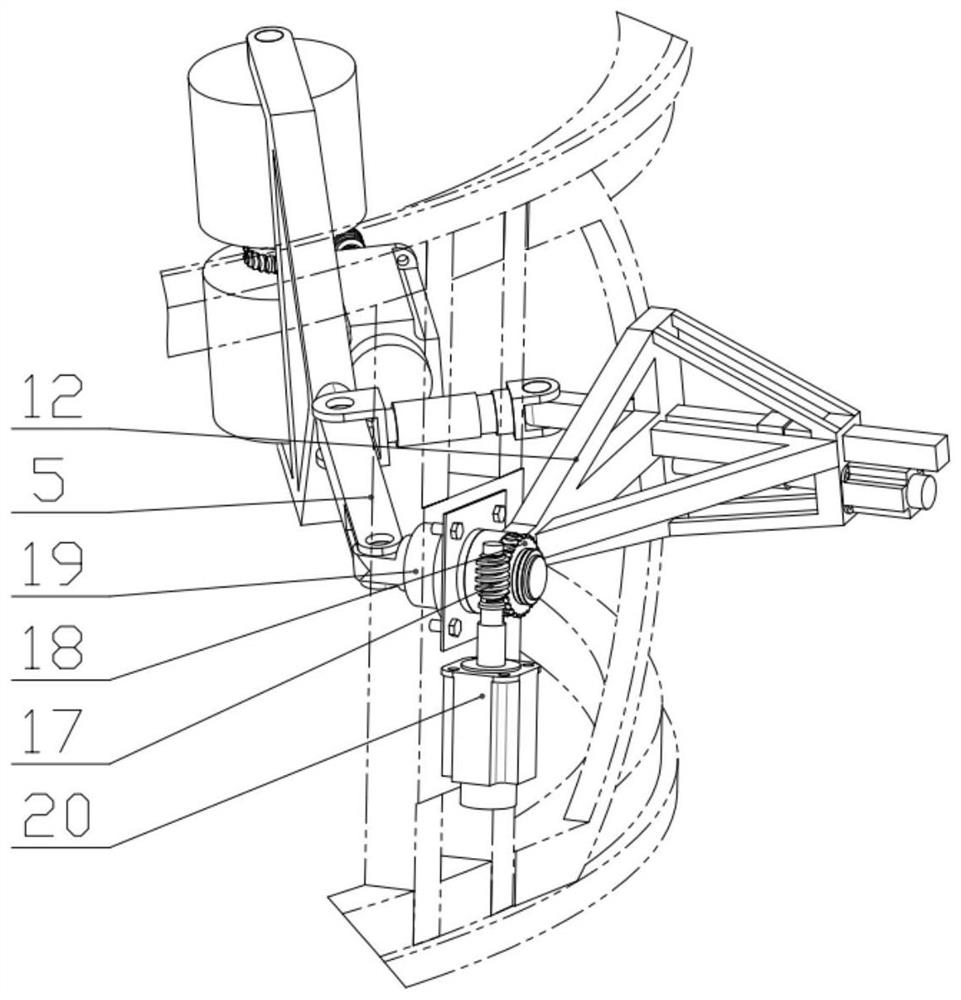

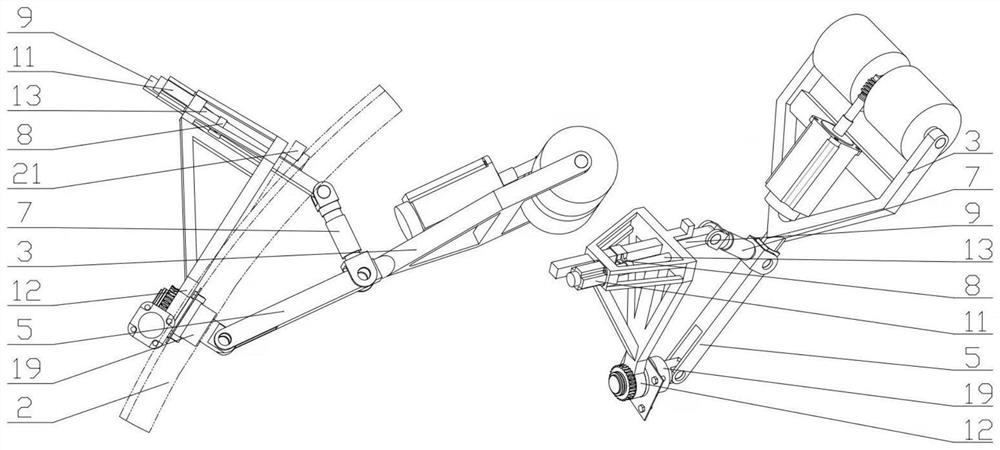

[0045] see Figure 1-4 The invention is a spiral climbing robot for a wind power tower. The center of the robot symmetrically surrounds the outer wall of the wind power tower, and the friction wheel is driven by a motor to spiral up and down on the tower wall. The four groups of angle adjustment mechanism, pressing mechanism and climbing mechanism on 2; during the working process of the spiral climbing robot, the motor works in coordination with each mechanism.

[0046] The climbing robot is also provided with a chassis 10 to prevent dust and foreign objects from entering.

[0047] The angle adjustment mechanism is used to adjust the lead of the helical track at all times. When running to the taper position, the four symmetrically installed pressing mechanisms are synchronously pressed, and the rotating pressure rods 3 of the four climbing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com