Environment-friendly antibacterial polymer emulsion building waterproof coating and preparation method thereof

A technology of polymer emulsion and building waterproofing, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc. It can solve the problems of unsustainable antibacterial effect, poor antibacterial stability, and poor compatibility of bactericidal systems, etc. , to achieve long-term antibacterial performance, stable performance, and excellent waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method based on the environmental protection antibacterial polymer emulsion construction waterproof coating as described in any one of the above, comprising the following preparation steps:

[0038]Weigh the raw materials according to the proportion, add the deionized water into the liquid material mixing tank after metering, turn on the disperser of the mixing tank, keep the rotation speed at 180-220r / min, add the dispersant and defoamer in turn, and stir for 2-5 minutes ;

[0039] Add ethylene-polyvinyl acetate emulsion and plasticizer in turn, keep rotating speed 250-350r / min and stir for 3-6 minutes;

[0040] Slowly add nano-titanium dioxide, mica powder, and precipitated barium sulfate in turn, keep the rotating speed at 750-850r / min and stir for 18-22 minutes;

[0041] Slowly add basic magnesium hypochlorite and polyquaternary phosphine salt bactericides in turn, keep the rotating speed at 550-650r / min and stir fo...

Embodiment 1

[0047] Preparation of sample 1:

[0048] Weigh 400 parts of ethylene-polyvinyl acetate emulsion, 2 parts of polyquaternary phosphonium salt bactericide, 5 parts of basic magnesium hypochlorite, 20 parts of nano titanium dioxide, 150 parts of mica powder, 300 parts of precipitated barium sulfate, 30 parts of plasticizer parts, 4 parts of dispersant, 6 parts of defoamer and 90 parts of deionized water;

[0049] Add deionized water into the liquid material stirring tank, turn on the disperser of the stirring tank, keep the rotating speed at 200r / min, add dispersant and defoamer in turn, and stir for 3 minutes;

[0050] Add ethylene-polyvinyl acetate emulsion and plasticizer in turn, keep the rotating speed at 300r / min and stir for 5 minutes;

[0051] Slowly add mica powder, precipitated barium sulfate and nano-titanium dioxide in turn, keep the rotating speed at 800r / min and stir for 20 minutes;

[0052] Finally, slowly add polyquaternary phosphonium salt bactericide and basic ...

Embodiment 2

[0056] Preparation of sample 2:

[0057] The preparation method of sample 2 is the same as that of sample 1, except that 350 parts of ethylene-polyvinyl acetate emulsion, 1 part of polyquaternary phosphonium salt fungicide, 10 parts of nano-titanium dioxide, 100 parts of mica powder, 250 parts of precipitated barium sulfate, 20 parts of plasticizer, 3 parts of dispersant, 3 parts of defoamer, the properties obtained are shown in Table 1.

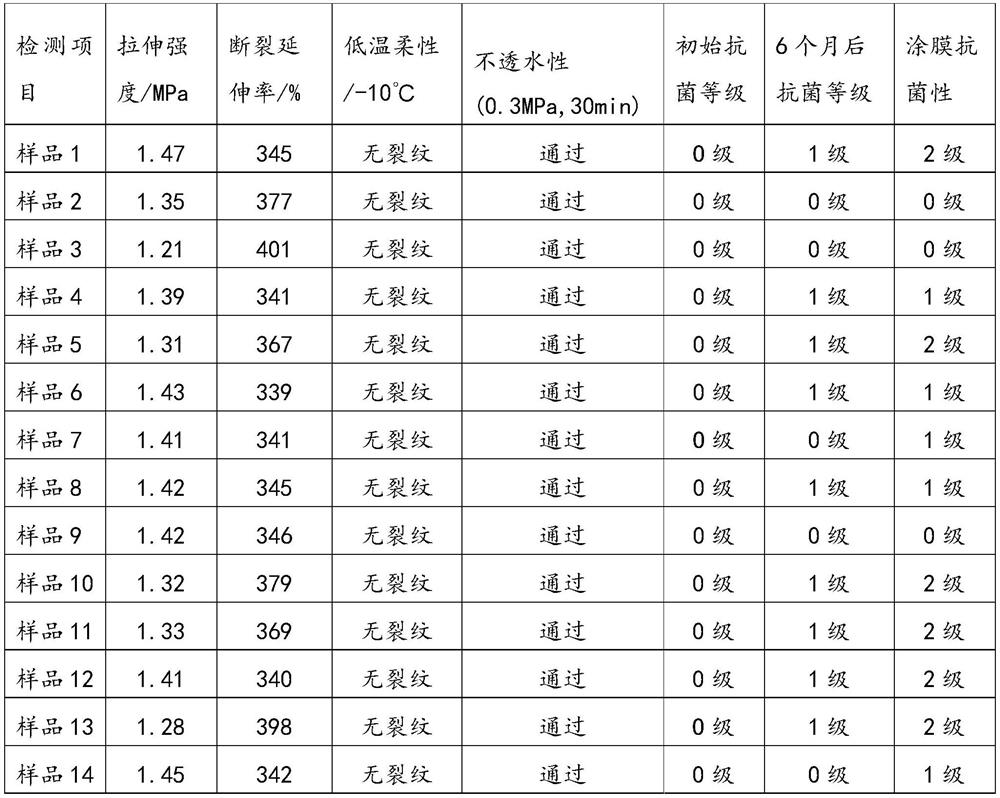

[0058] Through the comparison of sample 1 and sample 2, it is found that sample 1 is better than sample 2 in terms of tensile strength, elongation at break and antibacterial effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com