Preparation method of fruit cultivation bag bioactive coating green degradable antibacterial paper

A bioactive, fruit-cultivating bag technology, applied in coatings, special papers, pigment-containing coatings, etc., to achieve the effects of improving resistance, preventing the decline of antibacterial effects, and strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

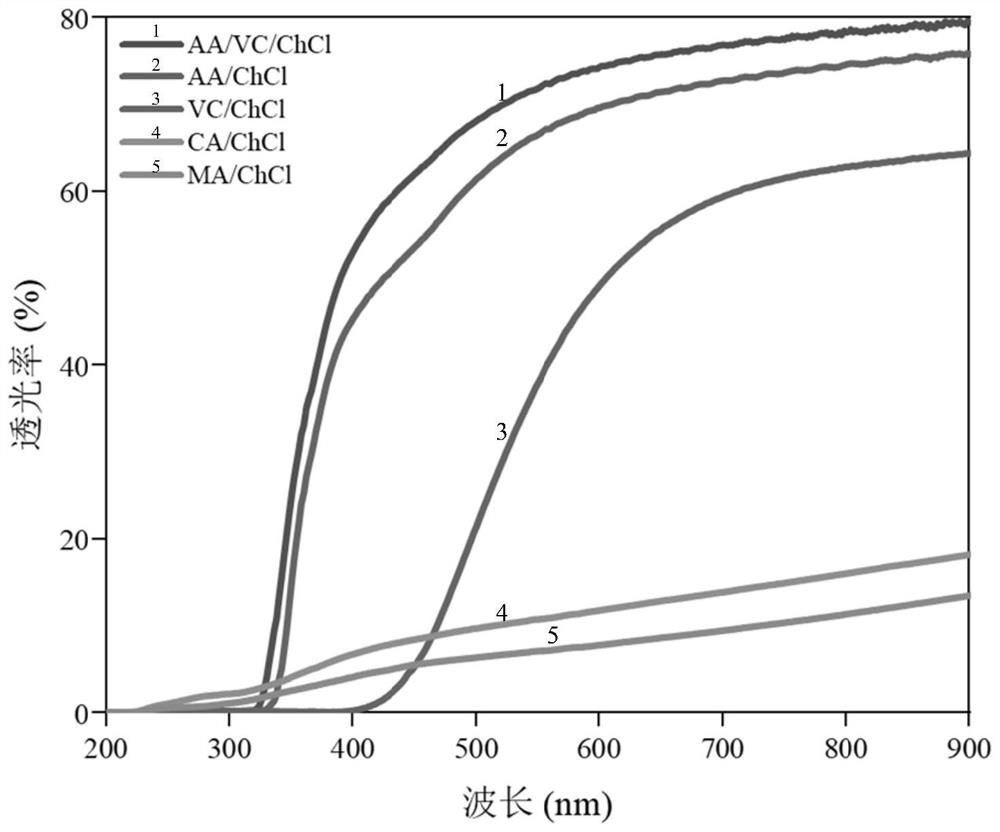

[0034] (1) Add 5g of sodium hexametaphosphate to 500mL of purified water, add 0.5g of nano-TiO 2 Add into the sodium hexametaphosphate solution, stir magnetically for 1 hour; add 50 g of starch to the solution, stir magnetically at 90°C for 1 hour to prepare the first layer of coating solution.

[0035] (2) Add 10 g of chitosan to 500 ml of purified water, add 7.5 mL of acetic acid, and stir magnetically for 1 h at 60°C to prepare a chitosan solution;

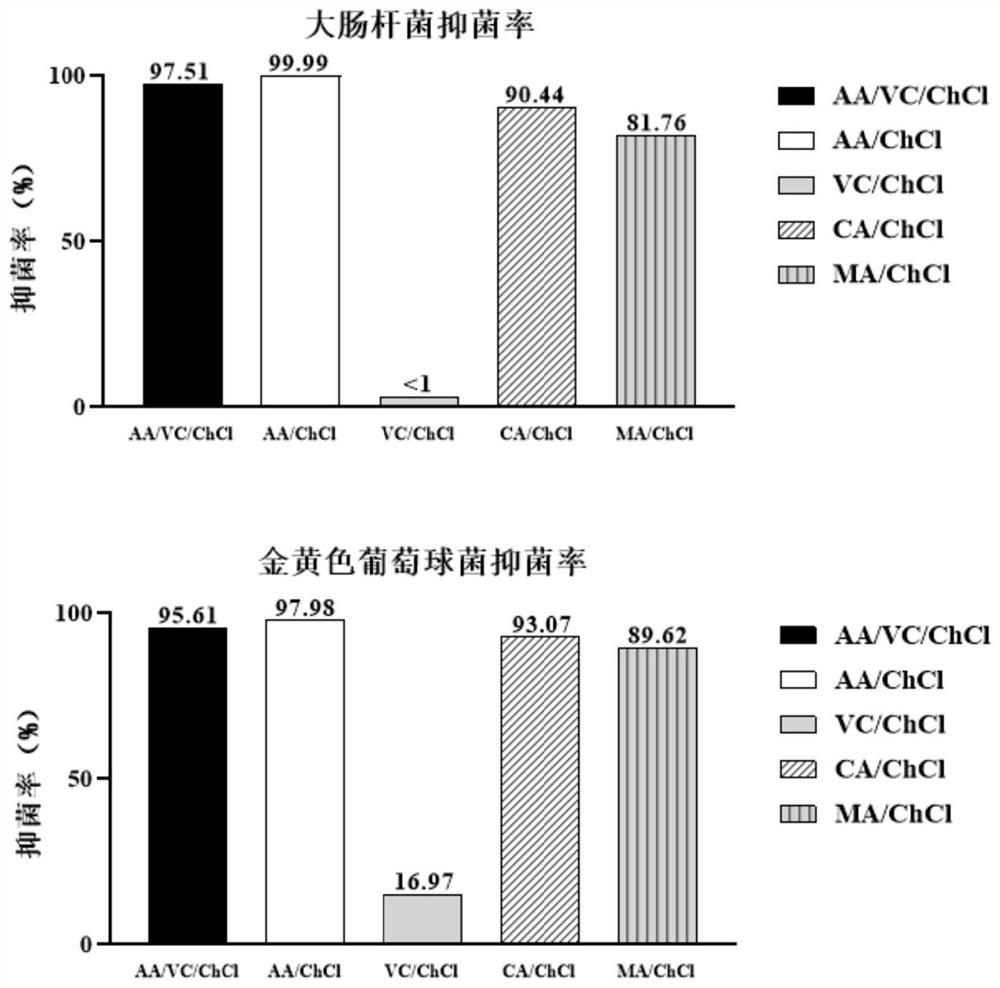

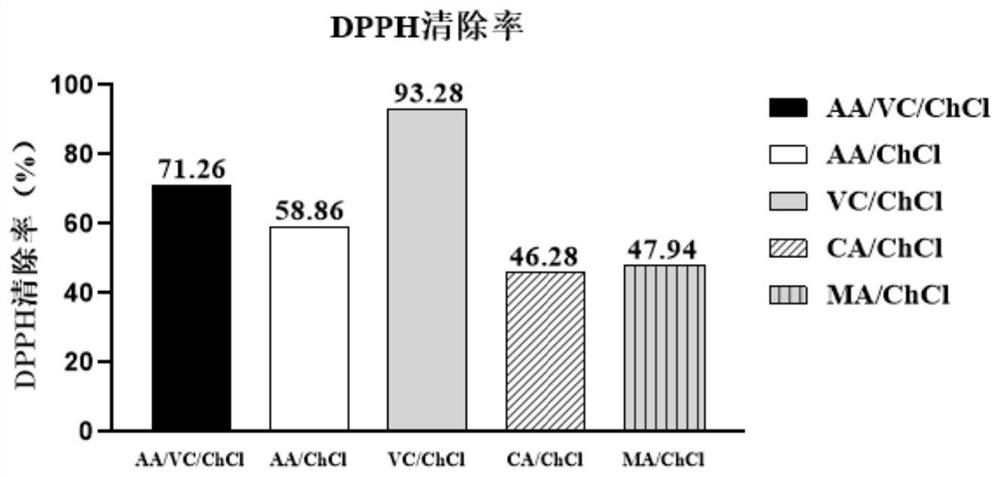

[0036](3) acetylsalicylic acid, ascorbic acid and choline chloride were mixed in a molar ratio of 1:1:3, and ball-milled at 600rpm for 30min at 50°C to obtain an organic acid deep eutectic solvent (AA / VC / CHCl) ;

[0037] (4) Pour more than 6 g of organic acid deep eutectic solvent into 500 mL of chitosan solution, and stir at 60° C. for 2 h to prepare a second layer of coating solution.

[0038] (5) The first layer of coating solution (800mL / m 2 ), the second layer of coating liquid (800mL / m 2 ) Coating the inner layer of t...

Embodiment 2

[0043] (1) Add 5g of sodium hexametaphosphate to 500mL of purified water, add 0.5g of nano-TiO 2 Add into the sodium hexametaphosphate solution and stir magnetically for 1 hour; add 50 g of starch to the solution and stir magnetically for 1 hour to prepare the first layer of coating solution.

[0044] (2) Add 10 g of chitosan to 500 ml of purified water, add 7.5 mL of acetic acid, and stir magnetically for 1 h at 60°C to prepare a chitosan solution;

[0045] (3) acetylsalicylic acid and choline chloride were mixed in a molar ratio of 1:1, and ball-milled at 600rpm for 30min at 50°C to obtain an organic acid deep eutectic solvent (AA / CHCl);

[0046] (4) Pour more than 6 g of organic acid deep eutectic solvent into 500 mL of chitosan solution, and stir at 60° C. for 2 h to prepare a second layer of coating solution.

[0047] (5) The first layer of coating solution (800mL / m 2 ), the second layer of coating liquid (800mL / m 2 ) Coating the inner layer of the fruit bag paper to f...

Embodiment 3

[0052] (1) Add 5g of sodium hexametaphosphate to 500mL of purified water, add 0.5g of nano-TiO 2 Add into the sodium hexametaphosphate solution and stir magnetically for 1 hour; add 50 g of starch to the solution and stir magnetically for 1 hour to prepare the first layer of coating solution.

[0053] (2) Add 10 g of chitosan to 500 ml of purified water, add 7.5 mL of acetic acid, and stir magnetically for 1 h at 60°C to prepare a chitosan solution;

[0054] (3) mixing ascorbic acid and choline chloride in a molar ratio of 1:2, and ball grinding at 600rpm for 30min at 50°C to obtain an organic acid deep eutectic solvent (VC / CHCl);

[0055] (4) Pour 6 g of different organic acid deep eutectic solvents into 500 mL of chitosan solution, and stir at 60° C. for 2 h to prepare a second layer of coating solution.

[0056] (5) Coat the first layer and the second layer of coating liquid on the inner layer of the fruit bag paper in turn to form a film, heat and dry the coated fruit bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com