Electric heating steel plate laminating method and laminating machine thereof

A technology of electric heating and laminator, which is applied in the direction of lamination, lamination devices, chemical instruments and methods, etc., and can solve problems such as inability to meet production needs, failure to become mainstream products, and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

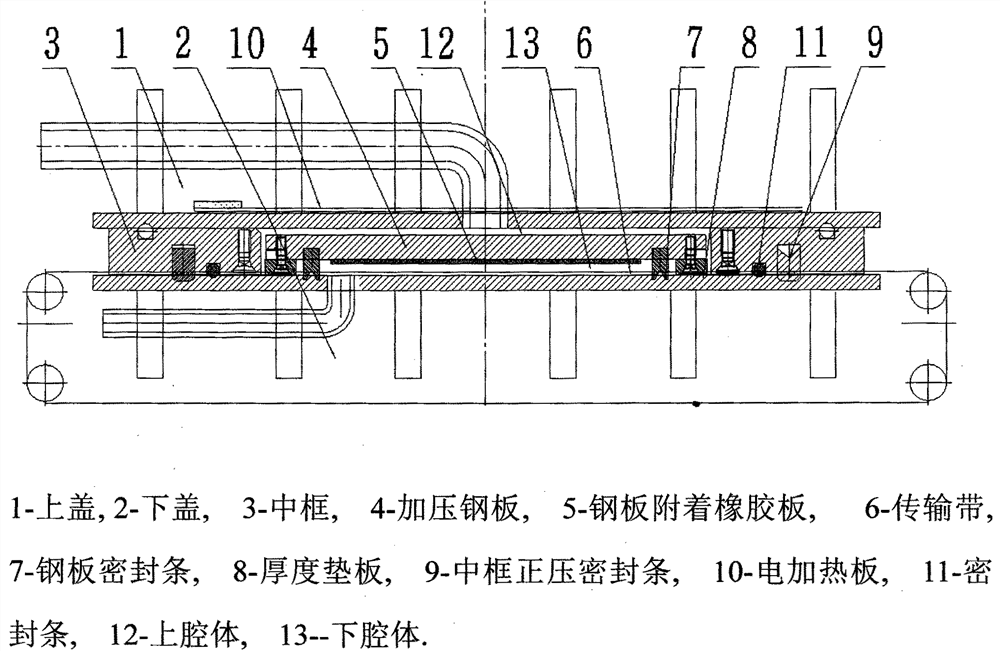

[0022] like figure 1 As shown, taking the laminator of solar cell pvb film double glass components as an example, the middle frame (3) is made of 30*100mm flat steel, the upper and lower sealing grooves are inlaid with sealing strips, and the upper cover (1), the lower cover ( 2) A sealed box is formed, the thickness of the steel plate (4) is 15mm, the lower wall (13) is formed by the sealing strip (7) and the lower cover (2), and the upper cavity is formed by the sealing strip (7) and the upper cover (1). (12).

[0023] The workpiece to be laminated, for example, the double-glass battery assembly to be laminated, enters the lower cavity (13) through the conveyor belt (6), the upper cavity (12) and the lower cavity (13) are evacuated at the same time, and heated, and the The laminated workpiece is heated to a certain temperature, such as 120 degrees Celsius, in a vacuum environment, the upper chamber (12) is slightly inflated, the vacuum is reduced by 30%, and the lower chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com