Method for converting Z-type alpha, beta-diaryl olefin compound into E-type alpha, beta-diaryl olefin compound

A technology for diaryl olefins and compounds, which is used in the preparation of chemicals, the conversion of α, β-diaryl olefin compounds from Z formula to E formula, which can solve the problem of large catalyst dosage, unstable conversion rate and broad substrate spectrum. problems such as poor performance, to achieve the effect of less catalyst dosage, low production cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] n=2, R 1 is n-propyl, R 2 , R 4 is a hydrogen atom, R 3 When it is a chlorine atom;

[0034] Preparation of compound II:

[0035]

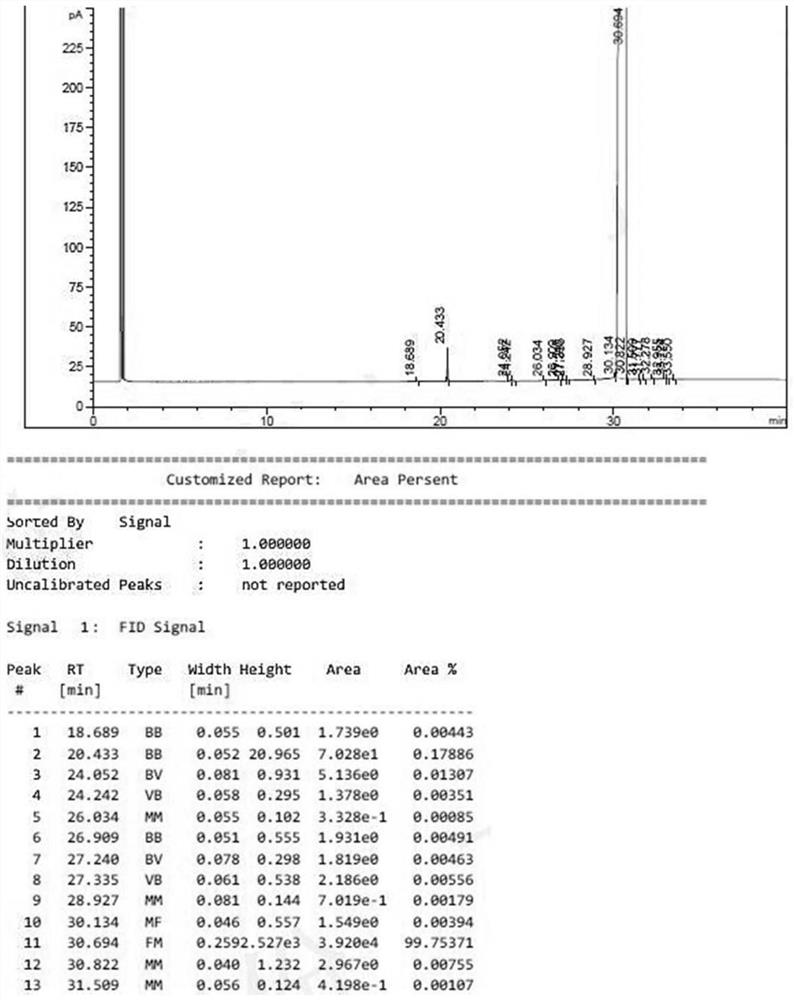

[0036] Under nitrogen protection, 166g (0.5mol) of compound I (compound I is the reaction substrate, wherein the composition GC ratio of compound I is E:Z=13:87), 498g of ethanol (solvent) were successively added to the clean and dry reaction flask. The feeding amount is based on the amount of compound I, the same below), 0.05g (0.00022mol) Pd(OAc) 2 , 0.19g (0.00044mol) CXA·HBr (the palladium catalyst and the phosphine ligand charging amount are converted according to the GC purity of Z formula in compound I, the same below), mechanically stir until the system is uniform, and it is a yellow and clear system.

[0037] Feeding is finished, be warmed up to 78 ℃ of temperature in the reaction flask, reflux insulation reaction for 8 hours, complete the reaction, be cooled to 50 ℃, cross 17g diatomaceous earth, filter, and dehydrate the ...

Embodiment 2

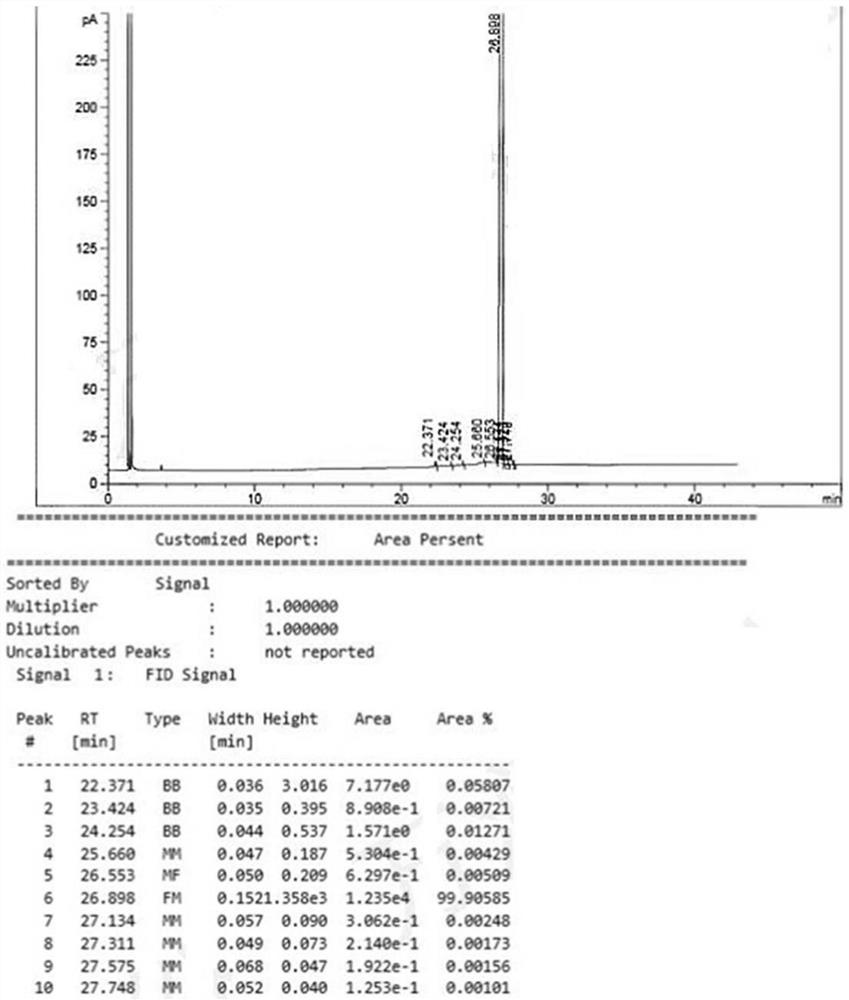

[0039] With embodiment 1, wherein different step is to use the PdCl of 0.04g 2 Instead of 0.05g (0.00022mol) Pd(OAc) 2 , the reflux holding time is 12h, and finally 149g of compound II is obtained, the yield is 90%, and the GC purity is 99.8%.

Embodiment 3

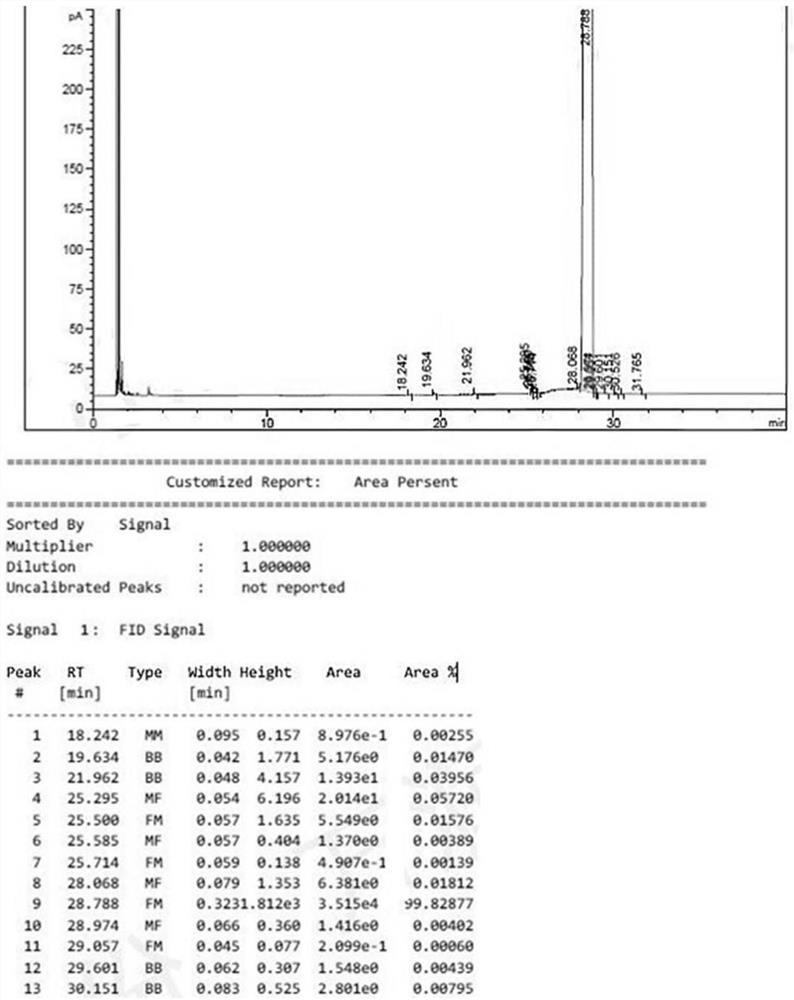

[0041] With embodiment 1, wherein different step is to use the PPh of 0.12g 3 Instead of 0.19 g (0.00044 mol) CXA·HBr, the reflux holding time was 10 h, and finally 141 g of compound II was obtained, the yield was 90%, and the GC purity was 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com