Pre-laid waterproof impervious coiled material with high puncture resistance and aging resistance and preparation method of pre-laid waterproof impervious coiled material

A waterproof, anti-seepage and anti-aging technology, which is applied in cement coatings, adhesive types, infrastructure engineering, etc., can solve problems such as uneven feeding, increased material costs, and reduced flexibility of coils, achieving good anti-permeation and Effects of puncture resistance, aging resistance improvement, and penetration resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

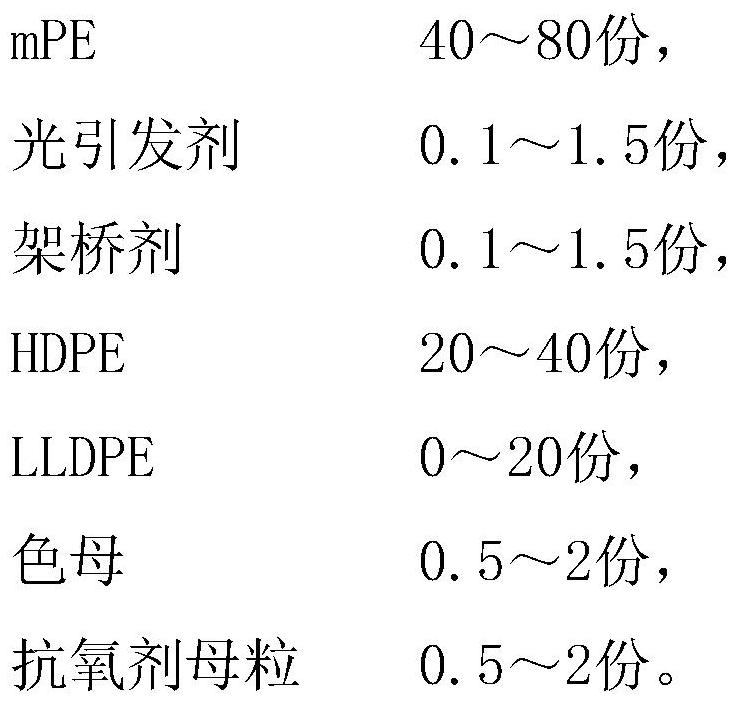

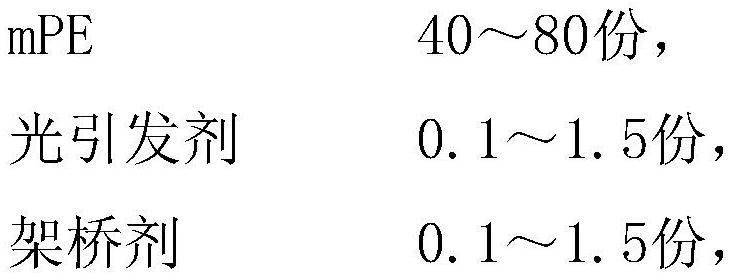

[0046]Weigh 60 parts by weight of mPE resin with a melt index of 2g / 10min, 0.5 part of photoinitiator (2-hydroxy-2methyl-1-phenyl-1-propanone), 0.3 part of bridging agent (triene) propyl isocyanurate) into the mixing kettle for full mixing, and the stirring speed is 200 RPM; the mixture is put into the twin-screw granulator, extruded and plasticized, pulled by strands, and water-cooled and dried to obtain a diameter of 0.6-0.9 mm. The extruded strip; the extruded strip is irradiated by an ultraviolet irradiation lamp in the band of 300-400 nm, and the cumulative irradiation amount is 5000 mJ / cm 2 , and then pelletized by a pelletizer to obtain extruded pellets;

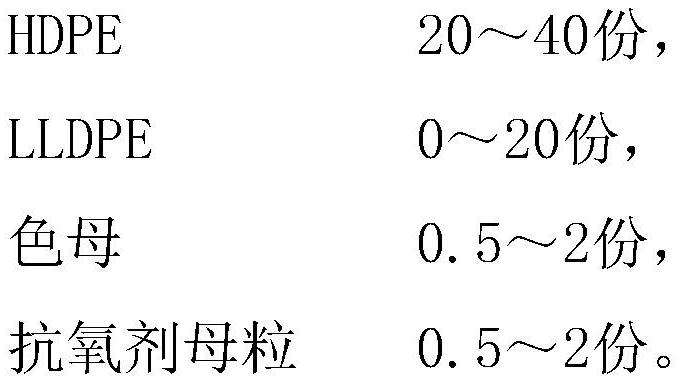

[0047] Weigh 60.7 parts of the above-mentioned extruded particles, 30 parts of HDPE with a melt index of 2.5g / 10min, 10 parts of LLDPE with a melt index of 1.9, 1 part of color masterbatch and 1 part of antioxidant masterbatch (antioxidant Tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythrito...

Embodiment 2

[0051] Weigh 60 parts by weight of mPE resin with a melt index of 2g / 10min, 1 part of photoinitiator (2-hydroxy-2methyl-1-phenyl-1-propanone), 0.8 part of bridging agent (triene) propyl isocyanurate) into the mixing kettle for full mixing, and the stirring speed is 200 RPM; the mixture is put into the twin-screw granulator, extruded and plasticized, pulled by strands, and water-cooled and dried to obtain a diameter of 0.6-0.9 mm. The extruded strip; the extruded strip is irradiated by an ultraviolet irradiation lamp in the band of 300-400 nm, and the cumulative irradiation amount is 5000 mJ / cm 2 , and then pelletized by a pelletizer to obtain extruded pellets;

[0052] Weigh 61.8 parts of the above-mentioned extruded particles and 30 parts of HDPE with a melt index of 2.5g / 10min, 10 parts of LLDPE with a melt index of 1.9, 1 part of color masterbatch and 2 parts of antioxidant masterbatch (antioxidant masterbatch) by weight. Tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)pr...

Embodiment 3

[0055] Weigh 60 parts by weight of mPE resin with a melt index of 2g / 10min, 0.5 part of photoinitiator (2-hydroxy-2methyl-1-phenyl-1-propanone), 0.3 part of bridging agent (triene) propyl isocyanurate) into the mixing kettle for full mixing, and the stirring speed is 200 RPM; the mixture is put into the twin-screw granulator, extruded and plasticized, pulled by strands, and water-cooled and dried to obtain a diameter of 0.6-0.9 mm. The extruded strip; the extruded strip is irradiated by an ultraviolet irradiation lamp in the band of 300-400 nm, and the cumulative irradiation amount is 5000 mJ / cm 2 , and then pelletized by a pelletizer to obtain extruded pellets;

[0056] Weigh 60.8 parts of the above-mentioned extruded particles and 30 parts of HDPE with a melt index of 2.5g / 10min, 10 parts of LLDPE with a melt index of 1.9, 1 part of color masterbatch and 0.5 parts of antioxidant masterbatch (antioxidant masterbatch) by weight. Tetrakis[beta-(3,5-di-tert-butyl-4-hydroxypheny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com