Antistatic polyester composition, preparation method thereof and polyester film

A composition and antistatic technology, which is applied in the field of polyester film, can solve the problems of poor antistatic property, poor dispersibility, and poor film transparency of polyester, and achieve excellent antistatic performance, improved dispersibility, and low humidity dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

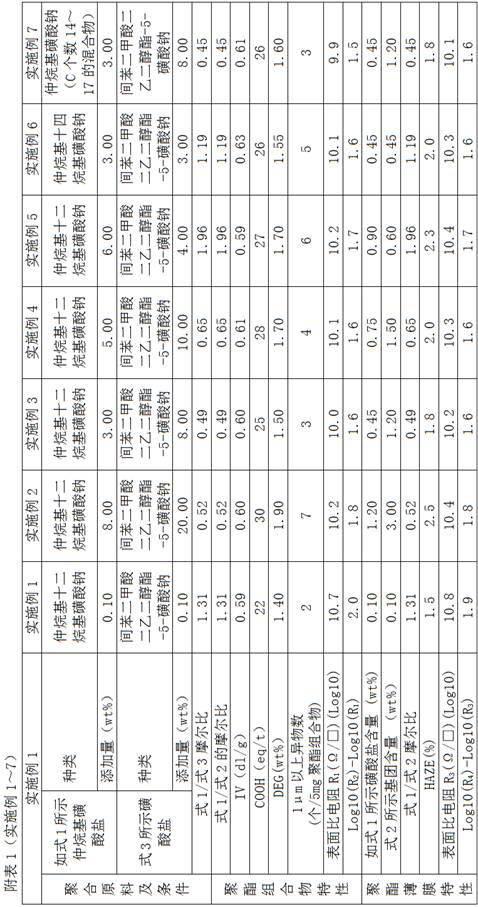

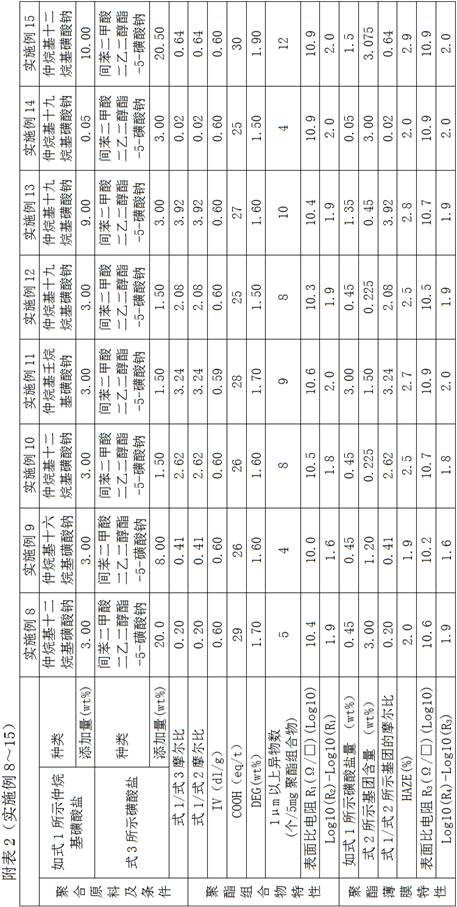

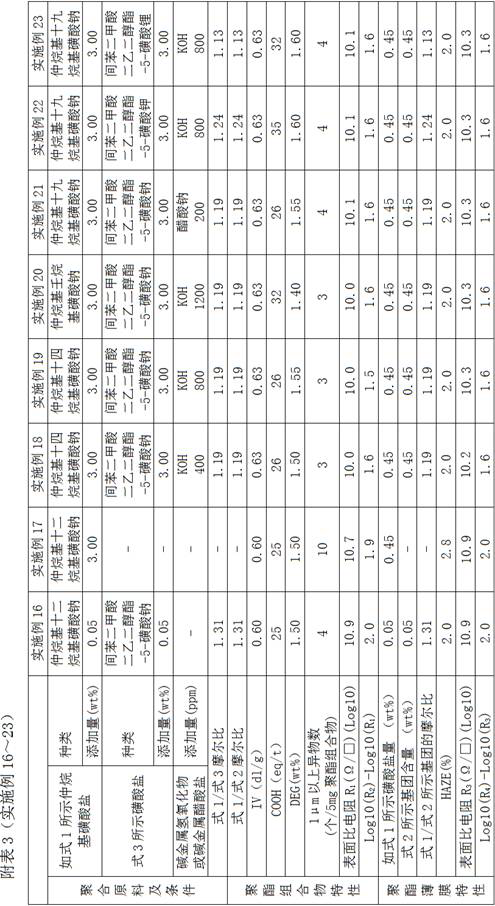

Examples

preparation example Construction

[0073] Another preparation method of the antistatic polyester composition disclosed in the present invention The specific steps of the blending method are as follows: the polyester chip and the secondary alkyl sulfonate shown in formula 1 are passed through a two-shaft kneader to obtain a polyester composition thing. The addition amount of the secondary alkyl sulfonate shown in Formula 1 is 0.05-10.00 wt % relative to the total amount of the polyester composition,

[0074] R 1 SO 3 M formula 1,

[0075] R in formula 1 1 is a secondary alkyl group with 8 to 22 carbon atoms, preferably a secondary alkyl group with 12 to 18 carbon atoms; M is an alkali metal Li, Na or K.

[0076] If the added amount of the secondary alkyl sulfonate shown in Formula 1 is less than 0.05 wt % relative to the total amount of the polyester composition, the sulfonic acid groups floating on the surface of the polyester are too few, and it is difficult to form a conductive path. There is no antistat...

Embodiment 1

[0121] The bishydroxyethyl terephthalate of 15kg was added to the esterification reaction tank, the temperature was maintained at 250°C, and the high-purity terephthalic acid of 8.0kg and the ethylene glycol slurry of 3.4kg were gradually added to the esterification reaction tank, The esterification reaction was carried out at 245° C. while water was flowing out to obtain an esterification reaction product. Then, the esterification reaction product obtained above was transferred into the polymerization reaction tank under heating at 250° C. through a transfer pipe connecting the esterification reaction tank and the polymerization reaction tank. After the transfer was completed, the mixture was stirred at 250°C for 5 minutes. After that, the polymerization catalyst antimony trioxide (AO) equivalent to 84 ppm of the total polyester was added, and after stirring for 5 minutes, diethylene glycol isophthalate-5-sulfonic acid equivalent to 0.10 wt% of the total polyester was added ...

Embodiment 2

[0125] The bishydroxyethyl terephthalate of 15kg was added to the esterification reaction tank, the temperature was maintained at 250°C, and the high-purity terephthalic acid of 8.0kg and the ethylene glycol slurry of 3.4kg were gradually added to the esterification reaction tank, The esterification reaction was carried out at 245° C. while water was flowing out to obtain an esterification reaction product. Then, the esterification reaction product obtained above was transferred into the polymerization reaction tank under heating at 250° C. through a transfer pipe connecting the esterification reaction tank and the polymerization reaction tank. After the transfer was completed, the mixture was stirred at 250°C for 5 minutes. After that, add antimony trioxide (AO), a polymerization catalyst equivalent to 84 ppm of the total polyester, and add diethylene glycol isophthalate-5-sulfonic acid equivalent to 20.00 wt% of the total polyester after stirring for 5 minutes. Sodium, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com